Adjusting a chainsaw carburetor can seem daunting. But it’s easier than you think.

Understanding how to adjust a chainsaw carburetor is crucial for its performance. The carburetor controls the engine’s fuel and air mixture. A well-adjusted carburetor ensures smooth operation and extends the chainsaw’s life. Many chainsaw owners struggle with this task, but with the right guidance, you can do it yourself.

This guide will help you adjust your chainsaw carburetor with simple steps. You don’t need to be a mechanic to follow along. Whether you’re a beginner or experienced user, this will help you keep your chainsaw running efficiently. Ready to learn? Let’s dive in and make your chainsaw work like new.

Credit: deerassociation.com

Introduction To Chainsaw Carburetors

A chainsaw carburetor is a crucial component. It ensures the engine runs smoothly. A carburetor mixes fuel and air in the right ratio. This mixture is then sent to the engine for combustion.

Proper adjustment of the carburetor is essential. It affects the chainsaw’s performance and longevity. If the mixture is too rich or too lean, problems arise. Adjusting the carburetor can seem daunting but is manageable with the right knowledge.

Importance Of Proper Adjustment

Correctly adjusting the carburetor keeps your chainsaw running efficiently. It helps in maintaining the optimal performance. A well-adjusted carburetor ensures the chainsaw starts easily. It also reduces fuel consumption and minimizes emissions.

Proper adjustment prevents engine damage. It keeps the chainsaw from stalling. Inconsistent engine speed or power loss indicates a need for adjustment. Regular adjustment extends the chainsaw’s lifespan.

Common Carburetor Problems

Several issues can arise with a chainsaw carburetor. Identifying these problems is the first step in fixing them.

- Engine Flooding: Too much fuel entering the engine causes flooding. The chainsaw may not start.

- Lean Mixture: Not enough fuel in the mixture. This causes the engine to overheat. It also leads to a loss of power.

- Rich Mixture: Too much fuel in the mixture. This results in excessive smoke and poor performance.

- Idle Problems: The engine may not idle correctly. It can stall or run too fast.

Regular maintenance can prevent these issues. Keeping the carburetor clean is vital. Use the proper tools and methods for adjustments.

Credit: www.youtube.com

Tools And Safety Gear

Adjusting the carburetor on your chainsaw requires the right tools and safety gear. Proper preparation ensures the process is smooth and safe. Let’s explore the essential tools and necessary safety precautions.

Essential Tools

You’ll need a few basic tools to adjust the carburetor. A screwdriver set is crucial. Ensure you have both flat-head and Phillips screwdrivers. You might also need a special carburetor adjustment tool, often available at hardware stores. A tachometer can help measure the engine’s RPM, ensuring accurate adjustments. A clean cloth is useful for wiping away debris from the carburetor area.

Safety Precautions

Safety should always be a priority when working with a chainsaw. Wear protective gloves to prevent cuts and abrasions. Safety goggles shield your eyes from debris. A face mask can protect you from inhaling dust and fumes. Ensure your work area is well-ventilated. Keep a first-aid kit nearby in case of any accidents. Never work on a hot chainsaw. Allow it to cool down before starting any adjustments.

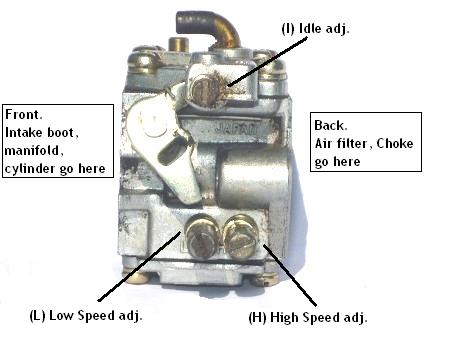

Identifying Carburetor Components

Understanding your chainsaw’s carburetor is crucial for optimal performance. This small device mixes fuel and air for combustion. Identifying its components helps in proper adjustments. Let’s break down the main parts and their functions.

Main Parts

The carburetor has several key parts. These include the diaphragm, needle valve, idle jet, and high-speed jet. Each part has a specific role. Knowing these will make adjustments easier.

Functions Of Each Component

The diaphragm regulates fuel flow. It responds to engine pressure changes. The needle valve controls fuel entering the carburetor. It ensures the correct amount is delivered.

The idle jet adjusts fuel for low-speed operations. It affects how smoothly the chainsaw runs at idle. The high-speed jet manages fuel for high-speed operations. It ensures enough fuel for cutting tasks.

Understanding these components is vital. It helps you keep your chainsaw running smoothly. Proper adjustments can extend its lifespan and efficiency.

Preparing Your Chainsaw

Adjusting your chainsaw carburetor requires careful preparation. Ensuring your chainsaw is in good condition is crucial. This involves a few key steps to make sure everything runs smoothly. Let’s dive into the essential preparations.

Cleaning The Chainsaw

Begin by cleaning your chainsaw. Remove any dirt and debris. A clean chainsaw works more efficiently. Wipe down the exterior with a clean cloth. Pay special attention to the air filter. A dirty air filter affects performance. Clean or replace it if necessary. Also, check the spark plug for any buildup. Clean it or replace it to ensure a strong spark.

Checking Fuel And Oil Levels

Next, check the fuel and oil levels. A chainsaw needs the right fuel mixture. Use fresh fuel to avoid problems. Stale fuel can cause issues. Ensure the oil reservoir is full. Proper lubrication keeps the chainsaw running smoothly. Regular checks prevent damage and extend the life of your tool. Lastly, inspect the fuel lines for cracks. Replace any damaged lines to prevent leaks.

Adjusting The Idle Speed

Adjusting the idle speed of your chainsaw is crucial for its performance. A well-adjusted idle speed ensures the chainsaw runs smoothly when not actively cutting. It also helps prevent engine stalling and unnecessary wear. To achieve this, you need to locate the idle screw and set the correct speed.

Locating The Idle Screw

First, find the idle screw on your chainsaw. It is usually near the carburetor. Look for a small, flat-head screw labeled “T” or “I”. This screw controls the idle speed of the engine. Check your chainsaw’s manual if you have trouble finding it.

Setting The Correct Speed

Turn on your chainsaw and let it warm up. Use a flat-head screwdriver to adjust the idle screw. Turn the screw clockwise to increase the idle speed. Turn it counterclockwise to decrease the idle speed. Adjust until the chainsaw runs smoothly without engaging the chain. Make small adjustments and check the engine’s response each time.

Tuning The Low-speed Jet

Tuning the low-speed jet on your chainsaw is crucial. It ensures smooth idling and efficient performance. This process involves locating and adjusting the low-speed screw. Let’s dive into the details.

Finding The Low-speed Screw

The first step is to find the low-speed screw. Look near the carburetor. Usually, it’s marked with an “L” on the body. This screw controls the fuel mixture at low speeds. It’s important to identify it correctly to avoid confusion with other screws.

Adjusting For Optimal Performance

Turn the low-speed screw gently clockwise until it lightly seats. Do not force it. Next, turn it counterclockwise one to one and a half turns. Start the chainsaw and let it warm up for a few minutes. Listen to the engine.

If the engine idles roughly, adjust the screw. Turn it slowly clockwise or counterclockwise. Find the point where the engine idles smoothly. Ensure the chainsaw responds well when the throttle is applied. This adjustment balances the fuel and air mixture at low speeds.

Patience is key. Small adjustments can make a big difference. Once the chainsaw runs smoothly at idle, your tuning of the low-speed jet is complete.

Adjusting The High-speed Jet

Adjusting the high-speed jet on your chainsaw can improve its performance. This adjustment controls the fuel mixture at full throttle. Correctly setting this ensures your chainsaw runs smoothly and efficiently.

Locating The High-speed Screw

First, find the high-speed screw on your chainsaw. It’s usually marked with an “H” on the carburetor. This screw adjusts the fuel flow at high speeds.

Use the chainsaw manual if needed. Every model may have slight differences. Ensure you have the right tool for the adjustment.

Fine-tuning For Peak Performance

Start the chainsaw and let it warm up. Once it’s ready, slowly turn the high-speed screw clockwise. This decreases the fuel flow.

Pay attention to the engine sound. If it starts to rev too high, turn the screw counterclockwise. This increases the fuel flow and lowers the RPM.

Find the sweet spot where the engine runs smoothly. Test by cutting some wood. Make small adjustments if needed.

Remember, fine-tuning is key. Patience will help you achieve the best performance.

Testing And Final Adjustments

After making the initial adjustments to your chainsaw carburetor, the next step is crucial. This involves testing and making final adjustments. This ensures your chainsaw runs smoothly and efficiently. Let’s dive into the details of this process.

Running The Chainsaw

Start your chainsaw and let it run for a few minutes. This warms up the engine. A warm engine gives more accurate readings. Pay close attention to the engine’s behavior.

- Listen for unusual sounds.

- Check the idle speed.

- Ensure the chainsaw runs smoothly.

If you notice any issues, you may need to make further adjustments.

Making Necessary Tweaks

Adjust the Low-Speed (L) and High-Speed (H) screws if needed. Use a screwdriver to make small adjustments.

- Turn the Low-Speed (L) screw clockwise until the engine runs smoothly.

- Turn the High-Speed (H) screw clockwise to increase RPM. Then, turn it counterclockwise until the engine sounds steady.

Check the throttle response. Squeeze the throttle trigger and let go. The chainsaw should accelerate smoothly. If it hesitates, tweak the screws again. Repeat until you achieve the desired performance.

| Adjustment | Purpose |

|---|---|

| Low-Speed (L) | Controls engine behavior at idle |

| High-Speed (H) | Controls engine behavior at full throttle |

Once you are satisfied with the adjustments, turn off the chainsaw. Let it cool down. Check the screws again. They should be tight. Your chainsaw is now ready for use.

Maintenance Tips

Regular maintenance of your chainsaw carburetor ensures it runs smoothly. Keeping it in good condition prevents potential problems. Here are some essential maintenance tips.

Regular Cleaning

Clean the air filter often. Dirt and debris can clog it. A clogged air filter reduces performance. It also affects fuel efficiency. Remove the air filter and clean it with soapy water. Let it dry completely before reinstalling.

Use a brush to remove dirt from the carburetor. Focus on the small parts. Ensure no debris remains. This helps the carburetor function properly.

Periodic Adjustments

Adjust the carburetor settings periodically. Use the adjustment screws for this. There are usually three screws. They control the idle speed, low speed, and high speed. Turn the screws slightly to find the best setting. This keeps the chainsaw running efficiently.

Listen to the engine sound. It should run smoothly without sputtering. Check the manual for specific instructions. Follow the guidelines for your chainsaw model.

Troubleshooting Common Issues

Adjusting a chainsaw carburetor can sometimes lead to common issues. These issues can affect the performance of your chainsaw. Understanding how to troubleshoot these problems is key. Below, we will discuss some typical problems and their solutions.

Engine Stalling

If your chainsaw engine stalls, it may be due to several reasons. First, check the air filter. A dirty air filter can restrict airflow. Clean or replace it if needed. Next, inspect the fuel filter. A clogged fuel filter can cause the engine to stall. Replace it if necessary.

Another common cause is incorrect carburetor settings. Make sure the idle speed screw is set correctly. Too low of an idle speed can cause stalling. Adjust the idle speed screw slightly to increase the RPMs. This should help stabilize the engine.

Poor Acceleration

Poor acceleration can be frustrating. It can slow down your work. Start by checking the fuel lines. Ensure there are no leaks or blockages. Clean or replace the fuel lines if needed. Next, examine the spark plug. A worn-out spark plug can affect acceleration. Replace it if it looks damaged or dirty.

Incorrect carburetor settings can also cause poor acceleration. The high-speed adjustment screw controls fuel flow at higher RPMs. Adjust the screw to find the right balance. Turn it slightly clockwise for more fuel and counterclockwise for less. Test the chainsaw after each adjustment.

Credit: www.youtube.com

Frequently Asked Questions

How Do I Adjust A Chainsaw Carburetor?

To adjust a chainsaw carburetor, locate the adjustment screws. Turn them to fine-tune the air and fuel mixture. Ensure the chainsaw runs smoothly at different speeds.

Why Is My Chainsaw Not Idling Properly?

A chainsaw may not idle properly due to incorrect carburetor settings. Adjust the idle screw to stabilize the engine. Check for air leaks and clean the air filter.

What Are The Signs Of A Bad Carburetor?

Signs of a bad carburetor include difficulty starting, poor idling, and engine stalling. The chainsaw may also run too rich or too lean.

How Often Should I Clean The Chainsaw Carburetor?

Clean the chainsaw carburetor every 20-30 hours of use. Regular maintenance ensures optimal performance and prevents clogs or build-up.

Conclusion

Adjusting your chainsaw carburetor improves performance and efficiency. Follow the steps carefully. Ensure safety by using protective gear. Regular maintenance keeps your chainsaw running smoothly. Don’t ignore any unusual sounds or behaviors. Proper adjustment ensures optimal fuel usage. Enjoy a smoother and more effective cutting experience.

Keep your chainsaw in top condition for longer life. Remember, a well-tuned carburetor is key to your chainsaw’s health. Happy cutting!