Yes, you can use a drill machine to drive screws. It’s a common practice.

But, there are some important things to know. Using a drill machine to drive screws can save time and effort. Many people prefer this method over a manual screwdriver. But, not all drills are the same. Some drills are better suited for driving screws than others.

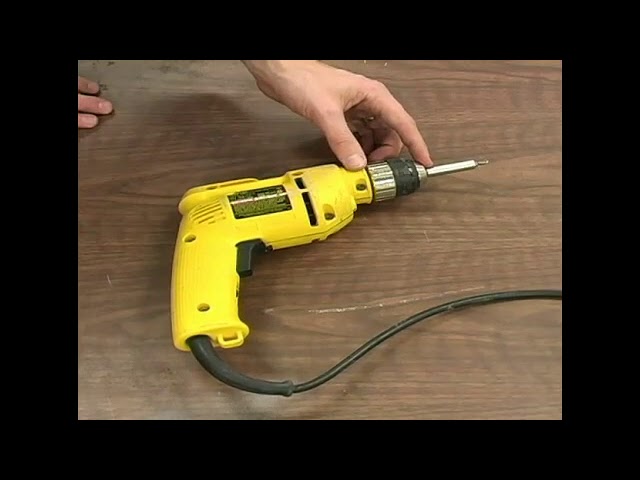

In this post, we’ll explore the best ways to use a drill machine for driving screws. We’ll discuss the types of drills and bits you need. We’ll also cover tips for getting the best results. By the end, you’ll know how to use your drill machine efficiently and safely. So, let’s get started!

Introduction To Using Drill Machines For Screws

Many people wonder, can we use a drill machine to drive screws? It’s a common question for both beginners and experienced DIY enthusiasts. Using a drill machine for screws can be a practical solution. Let’s dive into the benefits and clear up some common misconceptions.

Benefits Of Drill Machines

Drill machines save time. They can drive screws faster than manual screwdrivers. This is especially useful for large projects. Drill machines also reduce physical strain. Your hands and wrists won’t tire as quickly. They offer more power. Tough materials are easier to handle. Drill machines come with adjustable settings. You can control the speed and torque. This helps prevent overdriving or damaging screws.

Common Misconceptions

Some think drill machines are only for drilling holes. This is not true. Drill machines can drive screws effectively. Another misconception is that drill machines will damage screws. Using the right bit and settings can prevent this. People also believe drill machines are hard to control. With practice, anyone can handle them well. Some think drill machines are expensive. But, there are affordable options available.

Choosing The Right Drill Machine

Choosing the right drill machine is crucial for driving screws effectively. Not all drill machines are suitable for the task, so it’s important to select one that fits your needs. This section will guide you through the different types of drill machines and key features to look for.

Types Of Drill Machines

There are various types of drill machines available, each designed for specific tasks. Understanding the differences can help you choose the right one.

- Cordless Drill: Portable and easy to use. Ideal for light to medium tasks.

- Corded Drill: More powerful and doesn’t rely on battery life. Great for heavy-duty tasks.

- Hammer Drill: Suitable for drilling into hard materials like concrete and brick.

- Impact Driver: Specially designed for driving screws. Provides high torque and prevents stripping screws.

Key Features To Look For

When choosing a drill machine for driving screws, consider these key features:

- Torque Settings: Adjustable torque settings help control the driving force. Prevents overdriving or stripping screws.

- Variable Speed: Allows you to adjust the speed based on the task. Slower speeds are better for driving screws.

- Comfortable Grip: Ergonomic handles reduce hand fatigue. Look for soft rubber grips.

- Battery Life: For cordless drills, a long-lasting battery is crucial. Check the battery capacity before buying.

- Weight and Balance: A lightweight and well-balanced drill is easier to handle. Reduces strain during extended use.

Choosing the right drill machine involves understanding the types available and the key features that make driving screws easier. With the right tool, you can ensure efficient and effective work.

Essential Accessories For Driving Screws

Using a drill machine to drive screws can save you time and effort. To do this effectively, you need some essential accessories. These accessories ensure you can drive screws efficiently and securely. Below, we discuss the key accessories you should have.

Drill Bits

Drill bits are crucial when driving screws with a drill machine. Different screws require different bits. Ensure you have a variety of bits to handle various tasks. Below is a table listing common drill bits and their uses:

| Drill Bit Type | Use |

|---|---|

| Twist Drill Bits | General purpose, suitable for wood, metal, and plastic |

| Brad-Point Bits | Best for wood, provides clean holes |

| Masonry Bits | Ideal for concrete, brick, and stone |

Having the right bit makes driving screws easier and prevents damage. Always match the bit to the material you’re working with.

Screwdriver Attachments

Screwdriver attachments are another must-have accessory. These attachments convert your drill into a powerful screwdriver. They are available in various sizes and shapes to fit different screws. Here are some common types:

- Phillips Head: Most common, fits Phillips screws

- Flat Head: For slotted screws

- Torx: Star-shaped, used for higher torque applications

Using the correct attachment ensures a secure fit and prevents slipping. This reduces the risk of stripping the screw head.

In summary, having the right drill bits and screwdriver attachments is essential. These accessories make driving screws with a drill machine efficient and effortless. Equip your toolkit with these must-have items for any screwing task.

Credit: www.youtube.com

Preparing Your Drill Machine

Preparing your drill machine is key to driving screws efficiently. Proper preparation ensures precision and prevents damage. Let’s dive into the essential steps.

Setting The Torque

First, adjust the torque setting on your drill. Torque controls the force applied to the screw. Too much torque can strip the screw or damage the material. Check the manual for recommended settings. Use a low to medium torque for most tasks. This ensures control and prevents issues.

Adjusting The Speed

Next, adjust the speed of your drill. Speed settings vary for different materials. Use a lower speed for softer materials like wood. Higher speeds work better for harder materials like metal. Start slow and increase speed as needed. This gives you better control and precision. Always test on a scrap piece first. It helps you find the perfect speed.

By setting the torque and adjusting the speed, you prepare your drill machine effectively. This makes driving screws easier and more efficient.

Step-by-step Guide To Driving Screws

Using a drill machine to drive screws can save time and effort. Follow these simple steps to get the job done efficiently. This guide will walk you through the process, making it easy even for beginners.

Marking The Spot

First, decide where you want the screw to go. Use a pencil to mark the spot. This ensures precision and helps keep your project aligned. A clear mark also reduces mistakes during drilling.

Drilling Pilot Holes

Next, drill a pilot hole. This step is crucial to prevent wood from splitting. Choose a drill bit smaller than your screw. Place the bit on your mark and start drilling. Go slow and steady. Drill to the depth of the screw.

Common Mistakes To Avoid

Using a drill machine to drive screws can be convenient. Yet, many make common mistakes that can lead to frustration or damage. Knowing what to avoid can save time and effort.

Overdriving Screws

One common mistake is overdriving screws. This happens if you use too much force. The screw can go too deep into the material. This can weaken the hold and damage the surface. Use a clutch setting on the drill to control the depth. Adjusting it to a lower setting can prevent overdriving.

Using The Wrong Bit

Another frequent error is using the wrong bit. Different screws need different bits. A mismatched bit can strip the screw head. This makes it hard to drive or remove. Always match the bit to the screw type. Check the size and shape before starting the job. This ensures a better fit and smoother operation.

Safety Tips For Using Drill Machines

Using a drill machine to drive screws can be very efficient. But it can also be risky if not handled properly. To stay safe, follow these essential safety tips.

Wearing Protective Gear

Always wear protective gear. This includes safety goggles, gloves, and ear protection.

- Safety goggles: Protect your eyes from flying debris.

- Gloves: Keep your hands safe from sharp objects and vibration.

- Ear protection: Protect your hearing from loud noise.

Maintaining The Drill

Regular maintenance of your drill machine is crucial. Check the drill bits for wear and tear. Replace any damaged bits immediately.

- Keep the drill clean. Dust and debris can cause it to overheat.

- Lubricate the moving parts. This ensures smooth operation.

- Check the power cord. A damaged cord can be a fire hazard.

By following these safety tips, you can use your drill machine effectively and safely.

Credit: www.homedepot.com

Expert Tips And Tricks

Using a drill machine to drive screws can save time and effort. But, many people struggle with this task. Here are some expert tips and tricks to help you.

Choosing The Right Screws

Selecting the right screws is vital. Not all screws are the same.

- Wood Screws: Perfect for wood projects. They have a sharp point.

- Machine Screws: Used with nuts. They are not pointed.

- Sheet Metal Screws: Ideal for metal. They have sharp threads.

- Drywall Screws: Best for drywall. They have bugle-shaped heads.

Choose the screw based on your material. The right screw makes the job easier.

Handling Different Materials

Driving screws into different materials requires unique approaches.

| Material | Tips |

|---|---|

| Wood | Use a pilot hole to avoid splitting. Use a wood screw. |

| Metal | Use a self-tapping screw. Apply oil to reduce friction. |

| Drywall | Use drywall screws. Do not over-tighten to avoid damage. |

| Plastic | Use a low torque setting. Use a plastic screw. |

Each material has specific needs. Adjust your technique accordingly.

Maintenance And Care For Drill Machines

Using a drill machine to drive screws is possible but requires caution. Select the right bit and control the speed. This ensures screws are driven properly without damaging materials.

Maintaining your drill machine ensures it works efficiently for a long time. Proper care helps avoid frequent repairs and replacements. Here, you will learn simple steps to keep your drill in top shape.Cleaning The Drill

Regular cleaning keeps your drill running smoothly. After each use, wipe the exterior with a clean cloth. Remove dust and debris from the vents to prevent overheating. Use compressed air to blow out dirt from tight spots. Clean the chuck by opening it and brushing out any trapped particles. This prevents jamming and ensures secure bit holding.Storing Properly

Proper storage extends your drill machine’s lifespan. Store it in a cool, dry place to avoid rust and corrosion. Keep the drill in its case to protect it from dust and moisture. Avoid placing heavy objects on top to prevent damage. Ensure the battery is removed and stored separately if the drill is cordless. This prevents battery drain and prolongs its life. “`

Credit: www.homedepot.com

Frequently Asked Questions

Can A Drill Be Used As A Screwdriver?

Yes, a drill can be used as a screwdriver. Ensure you use the correct drill bit and set the torque to avoid stripping screws.

What Type Of Drill Is Best For Driving Screws?

A cordless drill is best for driving screws. It provides versatility and control, making the task easier and more efficient.

How Do You Drive Screws With A Drill?

To drive screws with a drill, select the right bit, set the torque, and apply steady pressure.

Is It Safe To Use A Drill For Screws?

Yes, it is safe to use a drill for screws. Use the proper settings and bits to avoid damage.

Conclusion

Using a drill machine to drive screws can be effective. It saves time and effort. Choose the right bit and settings for best results. Ensure the drill’s speed matches the screw type. Practice helps improve precision. Always keep safety in mind while working.

With these tips, you can drive screws efficiently with a drill machine. Happy DIYing!