A central air compressor is a powerful, stationary air system designed to supply compressed air to multiple locations within a workshop, garage, or even a home. Unlike portable compressors, it’s a permanently installed unit that provides a consistent and ample air supply for various tools and applications, making it ideal for serious DIYers and professionals seeking reliable performance.

Navigating the world of air compressors can feel a bit like trying to decipher a secret code, especially when you’re just starting out. You might be eyeing that nail gun for your next project or dreaming of a perfectly smooth finish with a spray painter. But then you hear terms like “CFM,” “PSI,” and suddenly you wonder, “What exactly is a central air compressor?” It’s a common question, and honestly, it can be a bit overwhelming. But don’t you worry! Think of me as your friendly guide. We’re going to break down what a central air compressor is, why you might want one, and how to understand its key features. By the end of this, you’ll feel much more confident about making the right choice for your needs.

Understanding the Basics: What is a Central Air Compressor?

At its heart, a central air compressor is a machine that takes in ambient air, compresses it, and stores it under pressure in a tank. This pressurized air can then be delivered through a network of pipes or hoses to various points where you need it. Think of it as the robust, workhorse of compressed air systems, designed for continuous or frequent use across a larger area.

Unlike smaller, portable compressors that you might wheel out for a specific task, a central air compressor is typically a larger, stationary unit. It’s often installed in a dedicated space, like a workshop or garage, and connected to a distribution system that can run throughout your workspace. This means you can plug in your air tools or connect your spray gun at multiple locations without having to move the compressor itself.

Why Choose a Central Air Compressor?

The decision to invest in a central air compressor usually comes down to the scale and nature of your projects. If you’re a serious DIY enthusiast, a hobbyist with a passion for automotive restoration, or someone who frequently uses multiple pneumatic tools, a central system offers significant advantages:

- Convenience: The biggest draw is the ability to access compressed air exactly where you need it. No more dragging a heavy compressor across the shop or constantly repositioning it.

- Power and Performance: Central units are generally more powerful and designed for higher duty cycles, meaning they can run tools that require a lot of air for extended periods without overheating or losing pressure.

- Durability: They are built to last and handle demanding work, often featuring cast-iron cylinders and robust construction.

- Efficiency: For larger operations, a single, well-sized central compressor can be more energy-efficient than running multiple smaller compressors.

- Versatility: From powering framing nailers and impact wrenches to running sanders, grinders, and paint sprayers, a central system can handle a wide array of pneumatic tools.

Key Components of a Central Air Compressor

To truly understand what a central air compressor is, it’s helpful to know its main parts and what they do:

1. Motor: This is the power source that drives the compressor pump. Motors can be electric (either single-phase or three-phase) or gas-powered. For most home workshops, electric is the standard.

2. Compressor Pump: This is the heart of the system. It’s responsible for drawing in air and compressing it. Pumps can be:

- Piston Pumps: The most common type. They work like an engine’s pistons, moving up and down to compress air. These can be single-stage (one compression stroke) or two-stage (air is compressed once, then compressed again for higher pressure). Two-stage is generally preferred for heavier-duty applications.

- Rotary Screw Compressors: Less common in home settings but found in industrial applications. They use two interlocking helical screws to compress air.

3. Air Tank: This is where the compressed air is stored. The size of the tank is crucial, as it acts as a buffer, providing a steady supply of air and allowing the motor to cycle less frequently. Larger tanks mean less frequent motor starts, which can extend the life of the compressor.

4. Pressure Switch: This automatically turns the motor on and off to maintain the desired pressure level within the tank. When the pressure drops below a set point, it turns the motor on; when it reaches the upper limit, it turns the motor off.

5. Safety Relief Valve: A critical safety feature that automatically releases excess pressure from the tank if the pressure switch fails, preventing a dangerous over-pressurization.

6. Check Valve: This valve prevents compressed air from flowing back from the tank into the pump when the compressor is running or stopped, ensuring that the pump doesn’t have to work against stored pressure when it starts up.

7. Drain Valve: Located at the bottom of the tank, this is used to release condensed water that naturally forms as air is compressed and cools. Regular draining is essential for preventing rust and maintaining air quality.

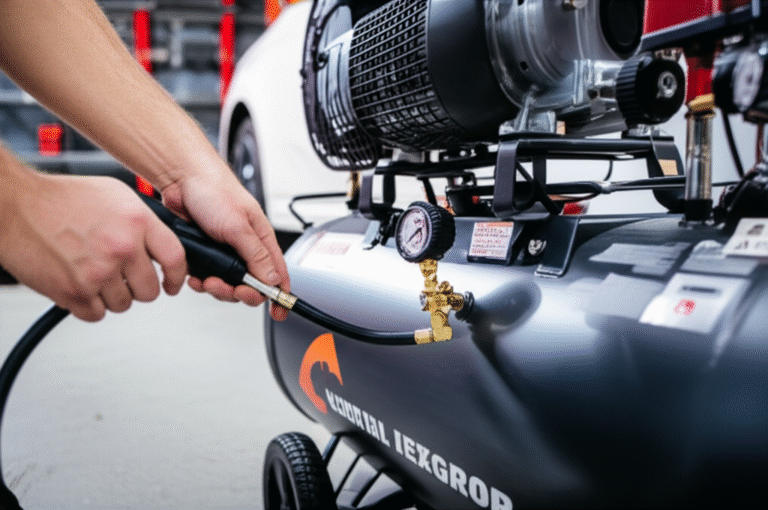

8. Regulator and Gauges: Gauges display the tank pressure and the regulated output pressure. The regulator allows you to set and control the air pressure delivered to your tools, ensuring they receive the correct amount for optimal performance and longevity.

Understanding the Key Specifications: CFM and PSI

When you’re looking at air compressors, two numbers will consistently pop up: CFM and PSI. Understanding these is non-negotiable for selecting the right compressor for your needs.

What is CFM? (Cubic Feet per Minute)

CFM measures the volume of air a compressor can deliver at a specific pressure. Think of it as the “flow rate.” Most air tools have a CFM requirement listed in their specifications. To power a tool effectively, your compressor needs to supply at least that much CFM. It’s often more important than PSI for determining if a compressor can run a particular tool.

Important Note: CFM ratings can vary depending on the pressure at which they are measured. Look for CFM ratings at 90 PSI, as this is a common operating pressure for many air tools.

What is PSI? (Pounds per Square Inch)

PSI measures the pressure of the compressed air. This indicates how much force the air can exert. Most air tools operate within a range of 70-100 PSI. A compressor’s maximum PSI rating tells you the highest pressure it can achieve, but it’s the CFM at your desired PSI that truly matters for tool performance.

How to Determine Your CFM Needs

This is where many beginners get a bit lost. The best way to figure out your CFM requirement is to:

- Identify Your Tools: List all the pneumatic tools you plan to use, now and in the foreseeable future.

- Check Tool Specifications: Look at the manufacturer’s specifications for each tool. They will usually state the required CFM at a specific PSI (e.g., 5 CFM @ 90 PSI).

- Add Them Up: If you plan to use multiple tools simultaneously, you need to add their CFM requirements together.

- Add a Buffer: It’s always wise to add a 25-50% buffer to your total CFM requirement. This accounts for potential future tool purchases, ensures the compressor isn’t constantly running at its absolute limit, and accounts for any slight pressure drops in your air lines.

Example: If your primary tool is a sander that needs 8 CFM @ 90 PSI, and you might occasionally use a smaller impact wrench needing 3 CFM @ 90 PSI, your combined need is 11 CFM @ 90 PSI. Adding a 30% buffer means you should look for a compressor that can deliver at least 14.3 CFM @ 90 PSI.

Compressor Tank Size: How Much is Enough?

Tank size, measured in gallons, determines how much compressed air is stored. A larger tank means:

- The compressor can run tools for longer periods without the motor cycling on.

- The motor cycles less often, leading to less wear and tear.

- A steadier supply of air, especially for tools that consume air rapidly.

While CFM is king for tool performance, tank size is crucial for efficiency and longevity. For a central system, tanks typically range from 60 gallons all the way up to 200+ gallons. A good starting point for a serious home workshop might be 60-80 gallons, but this depends heavily on your tool usage.

Types of Central Air Compressors by Horsepower and Stages

When looking at central compressors, you’ll see ratings for horsepower (HP) and whether they are single-stage or two-stage.

Horsepower (HP)

Horsepower indicates the motor’s power. While it’s a common metric, it’s not always the best indicator of performance. A well-designed compressor with a lower HP motor might outperform a poorly designed one with a higher HP motor. Focus on the CFM rating at 90 PSI as a more reliable measure. However, for a central unit, you’re typically looking at motors in the 3 HP to 5 HP range or higher.

Single-Stage vs. Two-Stage Compressors

This refers to how the air is compressed:

- Single-Stage: Air is compressed in one stroke by the piston. These are generally less efficient and produce lower pressures (typically up to 135 PSI). They are suitable for lighter-duty tasks and tools that don’t require high pressure or continuous airflow.

- Two-Stage: Air is compressed by the piston, then cooled slightly and compressed a second time. This process results in higher pressures (typically 175 PSI or more) and more efficient operation. Two-stage compressors are ideal for demanding tools like impact wrenches, sanders, and grinders, and are the preferred choice for most central air compressor setups.

Here’s a quick comparison:

| Feature | Single-Stage Compressor | Two-Stage Compressor |

|---|---|---|

| Compression Process | One stroke | Two strokes (with intercooling) |

| Max Pressure | Up to ~135 PSI | Up to ~175 PSI or higher |

| Efficiency | Lower | Higher |

| Duty Cycle | Intermittent use, lighter duty | Continuous use, heavier duty |

| Ideal For | Light inflation, air brushing, small brad nailers | Impact wrenches, sanders, grinders, automotive repair, painting |

Installation and Air Distribution

Installing a central air compressor is a more involved process than simply plugging in a portable unit. It typically involves:

- Location: Choosing a well-ventilated space, away from living areas if possible, as compressors can be noisy. A garage or dedicated workshop is common.

- Power Supply: Most central compressors require a dedicated 240-volt circuit, meaning you’ll likely need an electrician to install the proper wiring and breaker.

- Piping: Compressed air is distributed through a network of pipes. Copper or galvanized steel are common materials. The pipe diameter should be adequate to minimize pressure drop over long runs.

- Air Lines and Drops: From the main distribution pipes, you’ll install “drops” or take-off points with quick-connect fittings where you can attach your air hoses.

- Filtration and Drying: For applications like painting, you’ll want to include air filters and potentially an air dryer to remove moisture and contaminants, ensuring optimal air quality.

The installation of piping and electrical components should ideally be done by qualified professionals to ensure safety and compliance with local codes. For more information on compressed air systems, the Pumpschool website provides excellent resources on the principles of compressed air systems.

Maintenance for Longevity

Even the most robust central air compressor needs regular care to perform optimally and last for years. Here are the essential maintenance tasks:

- Drain the Tank Daily: This is the most critical step. Open the drain valve at the bottom of the tank at the end of each day’s use to release accumulated moisture. Failure to do this can lead to rust and tank damage.

- Check Oil Levels (if applicable): Many piston compressors require oil. Check the oil level regularly and top it up as needed. Change the oil according to the manufacturer’s recommendations (usually annually or after a certain number of operating hours).

- Clean or Replace Air Filters: The air intake filter prevents dust and debris from entering the pump. Clean it regularly and replace it when it becomes worn or clogged.

- Inspect Belts: If your compressor has a belt-driven motor and pump, check the belt tension and condition periodically. Replace worn or frayed belts.

- Check for Leaks: Listen for any hissing sounds, which could indicate air leaks in hoses, fittings, or the tank itself. Leaks waste energy and reduce system efficiency.

- Clean the Exterior: Keep the compressor clean and free of dust and debris, especially around the motor and pump cooling fins, to ensure proper ventilation.

Following a regular maintenance schedule, as outlined in your compressor’s owner’s manual, is key to preventing breakdowns and ensuring consistent performance. For detailed maintenance guidelines and troubleshooting, resources like those from the Occupational Safety and Health Administration (OSHA) offer valuable safety and operational information.

Frequently Asked Questions (FAQs)

Q1: What is the difference between a portable and a central air compressor?

A portable air compressor is designed to be moved easily from job to job or around your workspace. A central air compressor is a stationary unit permanently installed to supply air to multiple locations via a pipe network.

Q2: How do I know if I need a central air compressor?

You likely need a central air compressor if you frequently use multiple air tools, require a consistent and high volume of air, or want the convenience of accessing compressed air at various points in your workshop without moving the compressor.

Q3: What CFM rating do I need for my tools?

Check the specifications of your air tools. Add up the CFM requirements of all tools you might use simultaneously and add a 25-50% buffer. Always aim for a compressor that meets or exceeds the highest CFM requirement of your most air-hungry tool at your desired operating PSI (usually 90 PSI).

Q4: Is a two-stage compressor always better than a single-stage?

For central air compressor applications and most demanding tools, yes, a two-stage compressor is generally better due to its higher pressure output and greater efficiency. Single-stage compressors are typically sufficient for very light-duty tasks.

Q5: How large of a tank do I need?

Tank size is more about how long you can run tools before the compressor cycles on again. For demanding, continuous use, a larger tank (e.g., 60-80 gallons or more) is beneficial. For intermittent use, a smaller tank might suffice, but larger is generally preferred for central systems to reduce motor wear.

Q6: Can I run my central air compressor in my basement?

Yes, but ensure the area is well-ventilated, as compressors generate heat and can be noisy. Proper electrical wiring and consideration for vibration dampening are also important.

Q7: What kind of maintenance does a central air compressor require?

Key maintenance includes daily draining of the tank, checking oil levels (and changing it periodically), cleaning or replacing air filters, and inspecting belts. Always refer to your owner’s manual for specific recommendations.

Conclusion

So, there you have it! A central air compressor is a powerful, stationary system designed to deliver reliable compressed air throughout your workshop or garage. It’s an investment that can significantly boost your productivity and enjoyment of pneumatic tools, whether you’re a seasoned mechanic, a dedicated woodworker, or a passionate DIYer tackling ambitious projects.

By understanding the core components, key specifications like CFM and PSI, and considering your specific tool needs, you can confidently select a central air compressor that’s the perfect fit. Remember, proper installation and regular maintenance are crucial for ensuring your compressor operates efficiently, safely, and reliably for many years to come. Don’t hesitate to consult professional installers for the setup and always refer to your manufacturer’s manual for detailed care instructions. Happy building, and may your projects always be powered by perfectly compressed air!