An air compressor takes in ambient air, compresses it into a smaller volume, and stores it under pressure in a tank. This pressurized air is then released as needed to power pneumatic tools, inflate items, clean surfaces, and perform many other useful tasks around the home and workshop.

Ever stared at a shiny new air tool, or perhaps a flat tire that just won’t inflate, and wondered, “What exactly does this air compressor thingy do?” You’re not alone! Many of us see these machines and hear them humming, but the nitty-gritty of how they work and what they’re truly capable of can feel a bit mysterious. It’s like having a secret superpower for your home projects, but not knowing how to unlock it. Don’t worry, though! We’re going to break down the magic of air compressors in a way that’s easy to understand. By the end of this guide, you’ll know exactly what an air compressor does, why it’s such a versatile tool, and how it can make your DIY life so much easier. Let’s dive in and demystify this fantastic piece of equipment!

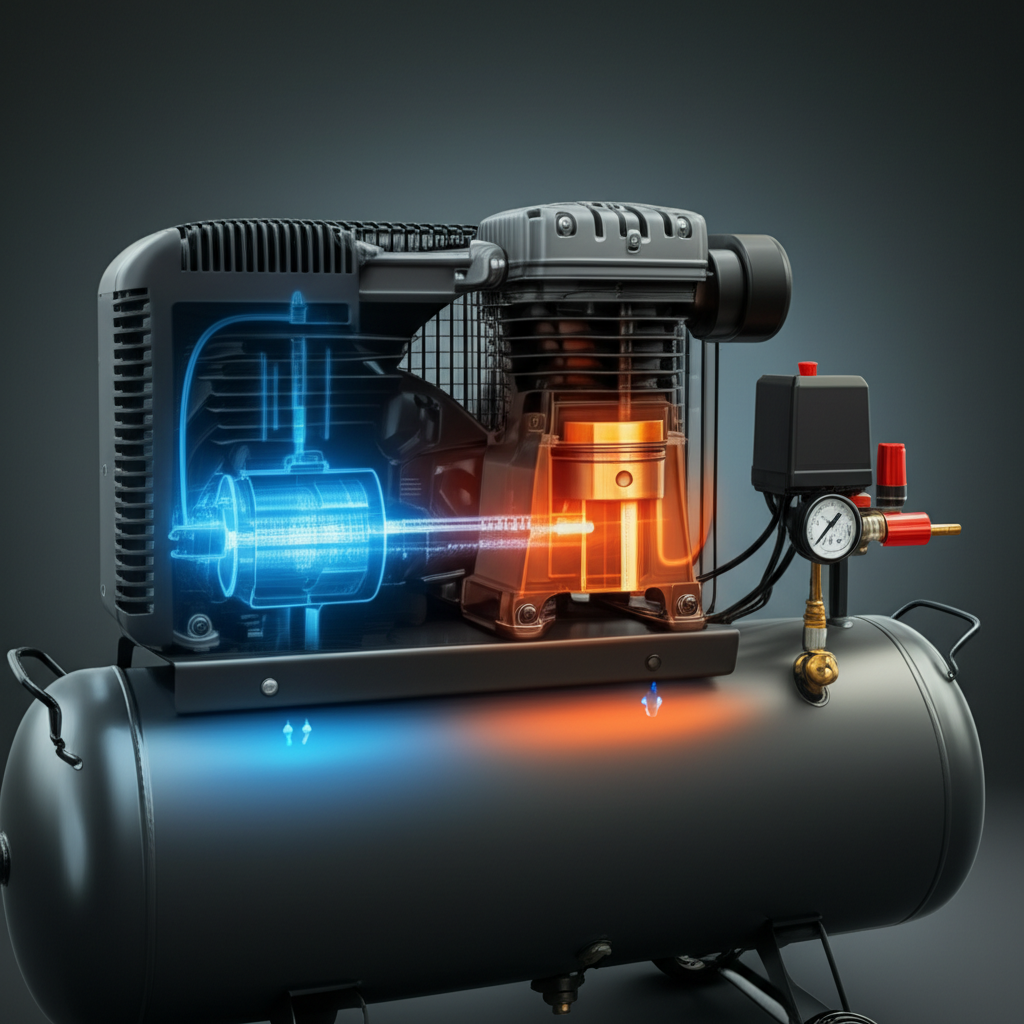

The Heart of the Machine: How an Air Compressor Works

At its core, an air compressor is a device that converts electrical or gasoline power into stored energy in the form of compressed air. Think of it like a lung for your tools – it takes air from the environment, squeezes it down, and then gives you that powerful burst when you need it.

Here’s a simplified breakdown of the process:

- Intake: The compressor’s motor drives a pump. This pump has a mechanism (often a piston moving inside a cylinder) that draws in surrounding air through an intake filter. The filter is super important because it prevents dust, dirt, and other debris from entering the system, which could damage the compressor or the tools it powers.

- Compression: As the piston moves, it squeezes the air into a much smaller space. This process increases the air’s pressure and temperature.

- Storage: The high-pressure air is then pushed into a storage tank. This tank acts like a reservoir, holding a ready supply of compressed air. The tank also helps to cool the air and reduce pulsations from the pump.

- Regulation: Most compressors have a pressure gauge and a regulator. The regulator allows you to control the amount of pressure released from the tank. This is crucial because different tools require different air pressures to operate correctly and safely.

- Output: When you connect a tool to the compressor via an air hose, opening the tool’s trigger allows the stored, pressurized air to flow out, powering the tool.

The magic lies in this controlled release of stored energy. Instead of needing a separate motor for every air-powered device, one compressor can supply the “muscle” for a whole workshop full of tools.

Why Do We Need Compressed Air? The Versatility of Air Compressors

So, what can you actually do with compressed air? The answer is: a lot! Air compressors are incredibly versatile and can be found in garages, workshops, construction sites, and even homes for a variety of tasks. They are the backbone of many pneumatic (air-powered) tools.

Powering Your Favorite Tools

This is perhaps the most common reason people invest in an air compressor. Pneumatic tools are often more powerful, lighter, and more durable than their electric counterparts. Here are some popular examples:

- Impact Wrenches: Perfect for quickly tightening or loosening lug nuts on cars, or any job requiring high torque.

- Nail Guns/Staplers: Essential for woodworking, framing, trim work, and upholstery. They drive nails and staples with incredible speed and precision.

- Sanders (Orbital, Belt): Provide consistent power for smoothing surfaces, preparing wood for finishing, or removing rust.

- Die Grinders: Great for cutting, grinding, and polishing metal.

- Air Brushes: Used for detailed painting, model making, and even cosmetic applications, offering a fine, even spray.

- Blow Guns: A simple but effective tool for clearing dust, debris, and sawdust from work surfaces, tools, or even your clothes.

The consistent power delivery from an air compressor ensures these tools perform at their best, making your projects more efficient and enjoyable.

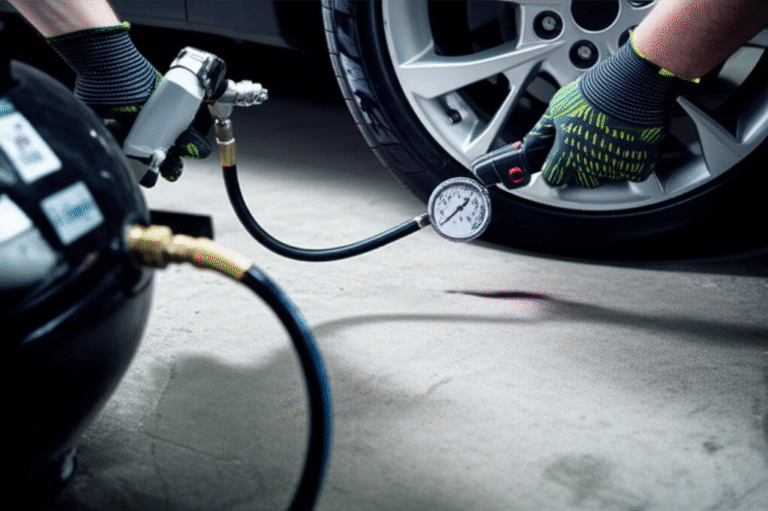

Inflating Tires and More

Beyond powering tools, air compressors are fantastic for inflating things:

- Car, Truck, and Bicycle Tires: Maintain optimal tire pressure for better fuel efficiency and safer driving.

- Sports Balls: Keep your basketballs, soccer balls, and footballs properly inflated.

- Inflatables: Quickly inflate air mattresses, pool toys, and bounce houses.

Many compressors come with convenient inflation adapters, making this a breeze.

Cleaning and Surface Preparation

The humble blow gun, powered by your air compressor, is a workshop essential:

- Clearing Dust and Debris: Blast away sawdust from your workbench, shavings from your tools, or dirt from hard-to-reach places.

- Drying Surfaces: Quickly dry painted or cleaned surfaces before the next step.

- Removing Loose Paint or Rust: With the right attachments, compressed air can help dislodge loose material.

Painting and Finishing

Air compressors are the heart of spray painting systems:

- Spray Guns: Achieve a smooth, professional finish on furniture, cars, walls, and more. The compressor atomizes the paint, creating a fine mist for even application.

- Airless Sprayers (some models): While distinct, some systems utilize compressed air for specific functions.

The ability to control air pressure is vital here, allowing for different spray patterns and paint flow rates.

Types of Air Compressors: Finding Your Match

Not all air compressors are created equal. They come in various sizes, power sources, and configurations, each suited for different needs. Understanding these differences will help you choose the right one.

By Power Source:

- Electric Air Compressors: These are the most common for home use and workshops. They plug into a standard electrical outlet.

- Pros: Quiet operation, no fumes, readily available power.

- Cons: Limited by cord length, require an electrical source.

- Gasoline-Powered Air Compressors: These are typically more powerful and portable, ideal for job sites where electricity isn’t readily available.

- Pros: High power, portability, independence from electrical outlets.

- Cons: Noisier, produce fumes, require fuel and maintenance, generally more expensive.

By Tank Size and Design:

The tank size is measured in gallons (gal) and is a key factor in how long you can run a tool before the compressor needs to refill. Airflow is measured in Cubic Feet per Minute (CFM) at a specific pressure (PSI – Pounds per Square Inch), which indicates how much air the compressor can deliver.

Here’s a general guide:

| Compressor Type | Typical Tank Size | Typical CFM | Best For | Common Tools Powered |

|---|---|---|---|---|

| Pancake/Hot Dog | 1-6 gallons | 0.5 – 2.5 CFM @ 90 PSI | Light-duty home use, inflation, small finish nailers. Very portable. | Brad nailers, framing nailers (some), tire inflators, blow guns. |

| Twin Stack | 10-30 gallons | 3.5 – 6.0 CFM @ 90 PSI | Medium-duty DIY, auto repair, general workshop use. | Impact wrenches, ratchets, sanders, spray guns (light use). |

| Vertical Stationary | 30-80+ gallons | 5.0 – 15.0+ CFM @ 90 PSI | Heavy-duty DIY, professional workshops, continuous tool use. | Heavy impact wrenches, grinders, sandblasters, multiple tool operation. |

| Wheelbarrow/Portable Vertical | 20-60 gallons | 4.0 – 8.0 CFM @ 90 PSI | Job sites, construction, tasks requiring more power and portability than pancake models. | Framing nailers, roofing nailers, small impact wrenches, sanders. |

When choosing, always check the CFM requirement of the tools you intend to use. A common rule of thumb is to select a compressor that provides at least 1.5 times the CFM your most demanding tool requires at its operating pressure (usually 90 PSI).

By Pump Type:

- Oil-Lubricated Compressors: These use oil to lubricate the pump’s moving parts. They are generally more durable and designed for heavy-duty, continuous use. They tend to be quieter and run cooler.

- Pros: Longer lifespan, better for demanding tasks, quieter.

- Cons: Require regular oil checks and changes, can be more expensive initially.

- Oil-Free Compressors: These are often found in smaller, more portable units. They use special materials in the pump that don’t require lubrication.

- Pros: Low maintenance (no oil changes), lighter, generally cheaper.

- Cons: Can be louder, may not last as long under heavy use, can run hotter.

Key Features to Look For

Beyond power and tank size, consider these features:

- CFM Rating: As mentioned, this is crucial. Ensure it meets your tool’s needs. You can find CFM ratings on the compressor’s specifications or tool packaging. For a good overview of CFM requirements for common tools, check out resources like Family Handyman’s Air Compressor Guide.

- PSI Rating: Most tools operate around 90 PSI. Compressors will typically have a maximum PSI rating, but the CFM at 90 PSI is the more important figure for tool performance.

- Horsepower (HP): While often advertised, HP is less critical than CFM. A higher HP doesn’t always mean more air output. Focus on CFM.

- Duty Cycle: This refers to how long a compressor can run before needing to cool down. A 50% duty cycle means it can run for 5 minutes out of every 10. For continuous use, look for 75% or 100% duty cycles.

- Noise Level: Measured in decibels (dB), this is important if you’re working in a residential area or sensitive environment. Some “quiet” models operate around 60-70 dB, while standard ones can be 80-90 dB or higher.

- Portability: Consider if you need to move it around your garage, to a job site, or if it will remain stationary. Look for wheels, handles, and overall weight.

- Air Quality: For painting or fine work, you might need an air dryer or filter to remove moisture and oil from the compressed air.

Using Your Air Compressor Safely

Safety is paramount when working with compressed air. The air is under high pressure, and improper use can lead to serious injury.

- Read the Manual: Always read and understand the manufacturer’s instructions for both the compressor and any tools you use.

- Wear Safety Glasses: Always wear ANSI-approved safety glasses or a face shield when operating or working near an air compressor or pneumatic tools.

- Check Hoses and Fittings: Ensure all air hoses, fittings, and couplers are in good condition, free from cracks or leaks, and rated for the pressure of your compressor.

- Regulate Pressure Correctly: Never exceed the maximum pressure rating of your tools or accessories. Use the regulator to set the appropriate pressure for each task.

- Don’t Aim Air at People or Pets: A blast of compressed air can cause serious injury.

- Drain the Tank Regularly: Water and oil can build up in the tank. Regularly drain the tank using the drain valve at the bottom to prevent corrosion and potential tank failure. This is a critical maintenance step. For more on this, consult the OSHA standard on compressed air safety.

- Proper Ventilation: If using a gas-powered compressor, ensure it’s used in a well-ventilated area to avoid carbon monoxide poisoning.

- Secure the Compressor: Make sure the compressor is on a stable, level surface to prevent tipping.

Maintenance: Keeping Your Compressor in Top Shape

Like any machine, your air compressor needs a little TLC to perform its best and last a long time.

- Drain the Tank: As mentioned, drain condensation daily or after each use.

- Check Oil Level (for oil-lubricated models): Top up or change the oil according to the manufacturer’s recommendations. Use only the recommended type of oil.

- Clean or Replace Air Filters: Clogged filters reduce efficiency. Check and clean/replace them regularly.

- Inspect Belts (if applicable): Some compressors have belts connecting the motor to the pump. Check for wear and proper tension.

- Tighten Fittings: Periodically check for loose fittings and tighten them to prevent air leaks.

- Keep it Clean: Dust and debris can interfere with cooling. Wipe down the compressor regularly.

Proper maintenance not only ensures your compressor works well but also prevents costly repairs down the line.

Frequently Asked Questions (FAQs)

Q1: What is the most important specification when buying an air compressor?

A1: The most important specification is the Cubic Feet per Minute (CFM) rating at 90 PSI. This indicates how much air the compressor can deliver, which directly affects whether it can power your tools effectively.

Q2: How do I know if I need an oil-lubricated or oil-free compressor?

A2: For heavy-duty, continuous use or if you want a quieter, longer-lasting machine, choose an oil-lubricated model. For lighter tasks, portability, and lower maintenance, an oil-free compressor is often sufficient.

Q3: Can I use my air compressor to paint a car?

A3: Yes, but you’ll need a compressor with a sufficient CFM output (often 5-10 CFM or more) and a suitable spray gun. You may also need air filters to ensure a clean, moisture-free air supply for a professional finish.

Q4: How often should I drain the air compressor tank?

A4: It’s best to drain the tank at least once a day, or after each use. This removes moisture that can cause rust and damage within the tank and the compressor system.

Q5: What’s the difference between PSI and CFM?

A5: PSI (Pounds per Square Inch) measures the force or pressure of the air. CFM (Cubic Feet per Minute) measures the volume or flow rate of the air. Most tools need a specific PSI to operate, but they will run out of power quickly if the CFM is too low.

Q6: My air compressor is making a loud noise. What could be wrong?

A6: Loud noises can be caused by several things: a loose belt, a worn-out pump, an issue with the motor, or even just normal operating noise if it’s an oil-free model. Check for loose parts first, and if the noise is unusual or concerning, consult your manual or a professional.

Conclusion

So, there you have it! An air compressor is far more than just a noisy box; it’s a powerful engine that drives a vast array of tools and tasks, from the intricate work of an airbrush to the brute force needed for an impact wrench. By understanding how it works, the different types available, and the importance of choosing one that matches your needs (especially that crucial CFM rating!), you’re well on your way to unlocking its full potential.

Remember to always prioritize safety, perform basic maintenance, and you’ll find your air compressor becomes an indispensable partner in all your DIY adventures, home repairs, and automotive projects. It’s an investment that pays dividends in efficiency, capability, and the sheer satisfaction of getting the job done right. Happy compressing!