Quick Summary:

Regularly check your AC compressor for unusual noises, vibrations, or leaks. Simple visual and auditory inspections can help identify potential issues early, saving you costly repairs and ensuring efficient cooling.

Hey there! If your air conditioner is acting up, especially when it’s hot outside, the compressor might be the culprit. It’s the heart of your AC system, working hard to keep your home cool and comfortable. When it’s not happy, nobody in the house is happy! Many homeowners worry about what to do when they suspect a problem with this vital part. Don’t fret! It’s more manageable than you might think. We’re going to walk through some straightforward ways you can perform essential checks on your AC compressor. By the end of this, you’ll feel much more confident in spotting potential issues before they become big, expensive headaches. Let’s get your cool air flowing again!

Understanding Your AC Compressor

Think of your air conditioner like a circulatory system for cool air. The compressor is the pump that keeps everything moving. It’s usually found in the outdoor unit of your split-system air conditioner. Its primary job is to compress the refrigerant, turning it into a hot, high-pressure gas. This gas then travels to the condenser coils, where it releases heat and condenses into a liquid. This cycle is what cools your home. Because it’s a mechanical component with moving parts, it can sometimes develop issues. Knowing what to look and listen for is the first step in keeping your AC running smoothly.

Why Compressor Checks Matter

Performing these checks might seem like a daunting task, but they’re crucial for a few key reasons:

- Preventative Maintenance: Catching small problems early can prevent them from turning into major, expensive repairs. A failing compressor can lead to a complete AC system breakdown.

- Efficiency: A healthy compressor operates more efficiently, meaning lower energy bills for you.

- Longevity: Regular checks and addressing minor issues promptly can extend the lifespan of your entire AC unit.

- Comfort: The most obvious reason – ensuring your home stays cool and comfortable during those hot summer months.

Essential AC Compressor Checks for Homeowners

When it comes to checking your AC compressor, it’s not about becoming an HVAC technician overnight. We’re focusing on simple, visual, and auditory checks you can do yourself. Always prioritize safety, and if anything feels beyond your comfort level, it’s best to call a professional.

1. Visual Inspection: Look for the Obvious

Before you even think about turning anything on, a good old-fashioned visual inspection can tell you a lot.

What to Look For:

- Debris and Obstructions: Ensure the area around your outdoor unit is clear. Leaves, grass clippings, branches, or anything else blocking airflow can cause the compressor to overheat and work harder. Gently remove any obstructions.

- Corrosion and Rust: While some minor surface rust on the casing is normal, extensive rust or corrosion, especially around electrical connections, could indicate a problem or an environment that’s not ideal for the unit.

- Oil Leaks: Look for any oily residue around the compressor unit or refrigerant lines. Refrigerant contains oil, and an oil leak often signifies a refrigerant leak, which is a serious issue.

- Damage to the Casing: Check for any dents, cracks, or other physical damage to the compressor housing.

- Electrical Connections: If you’re comfortable and the power is definitely off (more on safety later!), you can visually inspect the electrical connections for any signs of melting, charring, or loose wires.

Tools you might need:

- Gloves

- Safety glasses

- Flashlight

- Broom or leaf blower

2. Auditory Inspection: Listen to Your AC

Your ears can be incredibly helpful diagnostic tools when it comes to your AC compressor. The sounds it makes can tell you a lot about its health.

What to Listen For:

With the AC turned on and running, stand a safe distance from the outdoor unit and listen carefully.

- Normal Operation: A healthy compressor will typically make a humming sound. This is the motor doing its work.

- Loud or Unusual Noises:

- Grinding or Screeching: This often points to internal mechanical problems, like worn-out bearings or a failing motor. This is a critical sound to address immediately.

- Clicking: While a brief click when the unit starts up might be normal, persistent or loud clicking can indicate electrical issues or problems with the start capacitor.

- Buzzing: A loud buzzing could signal electrical problems, such as a faulty contactor or capacitor.

- Hammering: This sound, often described as “slugging,” can happen if liquid refrigerant enters the compressor, which is very damaging.

- Excessive Vibrations: While some vibration is normal, if the unit is shaking violently or vibrating excessively, it could mean the compressor is unbalanced, mounting bolts are loose, or there’s an internal issue.

Safety First!

Crucial safety note: Never touch the compressor or any electrical components while the unit is running or if you suspect an electrical issue. Always ensure the power to the outdoor unit is shut off at the breaker box before attempting any close-up inspections or touching any part of the unit. If you’re unsure about locating or using your breaker box, consult your home’s electrical panel manual or an electrician.

3. Checking for Proper Operation: Is it Cooling?

The ultimate test of your AC compressor is whether it’s effectively cooling your home. While this isn’t a direct compressor check, a lack of cooling is often a symptom of a compressor problem.

How to Assess Cooling:

- Feel the Air: Place your hand near an indoor vent. The air should feel noticeably cooler than the room temperature.

- Temperature Differential: For a more precise check, use a thermometer. Measure the temperature of the air entering your return vent and the air coming out of a supply vent. A healthy system typically has a temperature difference of 15-20 degrees Fahrenheit.

- Run Time: Does the AC run for a very long time without cooling the house? Or does it cycle on and off too frequently (short-cycling)? Both can be signs of a compressor struggling.

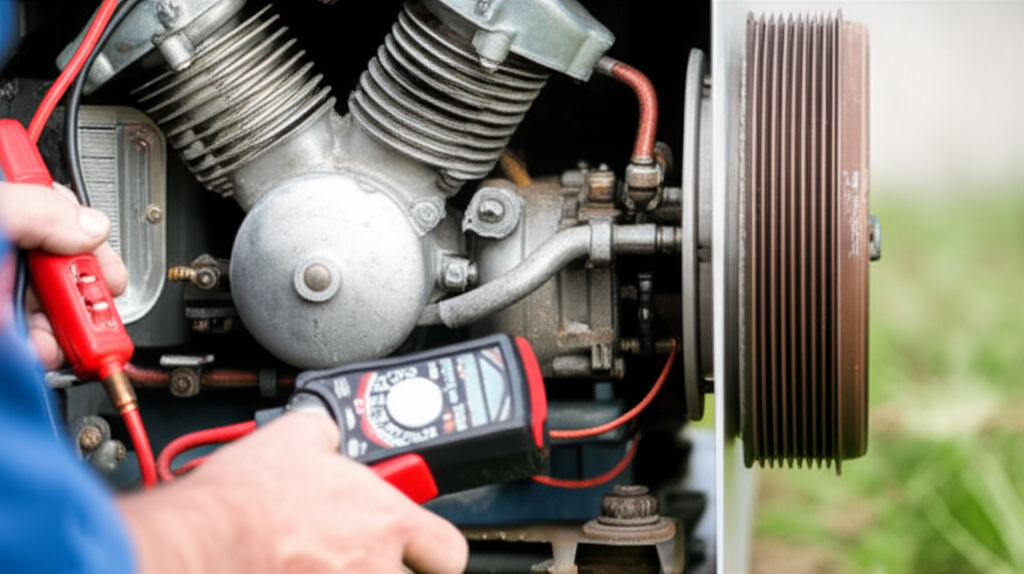

4. The Capacitor Check (Slightly More Advanced)

The start capacitor and run capacitor are electrical components that help the compressor motor start and run efficiently. A faulty capacitor is a very common reason for a compressor not starting or running properly.

What to Look For (Visual):

- Bulging or Leaking: If you can safely access the capacitor (with the power OFF!), look for any signs of bulging on the top or sides, or if it appears to be leaking oil.

When to Call a Pro:

Testing a capacitor requires a multimeter and knowledge of electrical safety. If you see any of the visual signs above, or if your compressor is humming but not starting, it’s highly recommended to call a qualified HVAC technician. They have the right tools and expertise to safely test and replace capacitors.

5. Refrigerant Level Checks (Professional Only)

While you can’t check refrigerant levels yourself safely or accurately, it’s important to understand that low refrigerant can impact compressor performance and lead to overheating. Signs of low refrigerant include:

- Frost buildup on refrigerant lines

- Weak cooling

- The AC system hissing or bubbling

If you suspect a refrigerant issue, this is definitely a job for a certified HVAC professional. Refrigerants are regulated, and handling them requires special training and equipment.

Troubleshooting Common AC Compressor Issues

Let’s break down some common scenarios and what they might mean for your compressor.

| Symptom | Possible Cause(s) | What to Do |

|---|---|---|

| Compressor hums but won’t start | Bad start capacitor, faulty starting relay, or internal compressor issue. | Turn off the AC. Call an HVAC professional. |

| Compressor makes loud grinding/screeching noises | Worn bearings, internal damage, or lack of lubrication. | Turn off the AC immediately. This is a serious issue. Call an HVAC professional. |

| AC not cooling, but fan is running | Compressor issue (not running or running inefficiently), low refrigerant, or dirty condenser coils. | Visually inspect condenser coils. Check for obvious compressor issues. If unsure, call a professional. |

| Excessive vibration from outdoor unit | Loose mounting bolts, unbalanced compressor, or internal component failure. | Check if unit is level and mounting bolts are tight (power off!). If vibration persists, call a professional. |

| Unit cycles on and off rapidly (short cycling) | Low refrigerant, oversized unit, or a thermostat issue. Compressor might be overheating. | Check for obvious refrigerant leaks or frost. Ensure thermostat is set correctly. Call a professional if it continues. |

When to Call a Professional HVAC Technician

While DIY checks are empowering, there are times when you absolutely need to call in the experts. These include:

- Anytime you are uncomfortable or unsure about a step.

- If you suspect a refrigerant leak (oily residue, hissing sounds, frost).

- If the compressor is making loud, unusual noises like grinding or screeching.

- If the unit is not cooling at all and you’ve ruled out simple issues like a tripped breaker or dirty filter.

- If you see any signs of electrical damage (scorching, melting, loose wires).

- If you need any internal components tested or replaced (capacitors, contactors, etc.).

Professionals have the specialized tools, knowledge, and safety equipment to diagnose and repair complex issues. They can also perform essential maintenance like cleaning condenser coils thoroughly and checking refrigerant charge levels accurately. Resources like the U.S. Department of Energy offer great advice on maintaining your home’s cooling system, which often involves professional servicing: Energy Saver: Home Cooling Systems.

AC Compressor Maintenance Tips

Beyond these checks, a little regular maintenance goes a long way in keeping your compressor healthy.

- Keep the Area Around the Unit Clean: As mentioned, clear away debris regularly.

- Clean Condenser Coils: Over time, the fins on your outdoor unit can get clogged with dirt and debris, hindering airflow. You can gently rinse them with a garden hose (power off!). For a deeper clean, a specialized coil cleaner can be used, but follow instructions carefully.

- Check and Clean Air Filters: A dirty air filter restricts airflow to the indoor unit, making the whole system work harder, including the compressor. Check your filter monthly and replace it when it looks dirty.

- Schedule Annual Professional Tune-Ups: This is perhaps the most important tip. An annual service by an HVAC technician can catch minor issues before they become major problems, ensure the system is running efficiently, and prolong its life.

Frequently Asked Questions (FAQ)

- How often should I check my AC compressor?

- It’s a good idea to do a quick visual check of the outdoor unit area every month during the cooling season. Listen for unusual noises whenever the AC is running. A more thorough visual inspection can be done seasonally.

- Can I touch the AC compressor while it’s running?

- Absolutely not. The compressor and its surrounding components can get very hot, and there are high-voltage electrical parts. Always ensure the power is turned off at the breaker before getting close or touching anything.

- What does it mean if my AC compressor is making a humming noise?

- A gentle humming sound is usually normal. It indicates the motor is running. However, if the humming is excessively loud, accompanied by vibrations, or if the unit isn’t cooling, it could signal a problem.

- Is it normal for my outdoor AC unit to be noisy?

- Some level of noise is normal, like the fan and the compressor motor humming. However, loud clanking, grinding, screeching, or excessive rattling is not normal and indicates a problem that needs attention.

- What is a capacitor, and why is it important for the compressor?

- Capacitors are electrical components that provide the necessary electrical surge to start the compressor motor and help it run smoothly. A faulty capacitor is a common reason for a compressor not starting or running erratically.

- Can I fix a compressor issue myself?

- Simple external cleaning and ensuring clear airflow are DIY tasks. However, internal compressor issues, electrical problems, or refrigerant handling require specialized knowledge and tools. For most compressor problems, it’s best to call a qualified HVAC technician.

- What’s the difference between the compressor and the fan in the outdoor unit?

- The fan’s job is to blow air across the condenser coils to release heat. The compressor is the component that pressurizes the refrigerant, which is a key part of the cooling cycle. Both are vital, but they have distinct roles.

Conclusion

Your AC compressor is a hardworking component, and by performing these simple checks, you’re taking proactive steps to ensure its health and the comfort of your home. Remember, a little attention can go a long way in preventing costly repairs and keeping your air conditioner running efficiently for years to come. Don’t hesitate to call a professional if you encounter anything that seems beyond your DIY capabilities. Staying informed and performing these essential checks will give you peace of mind and keep your cool, even on the hottest days!