Learn how to use an air compressor effectively and safely for DIY projects, tire inflation, and powering tools. This guide covers selection, setup, operation, and maintenance for beginners, ensuring you get the most out of your air compressor with confidence.

Hello there! If you’ve recently acquired an air compressor or are thinking about it, you might be wondering just how to get it up and running for your projects. It’s a common feeling, and honestly, these machines can seem a bit complex at first glance. But don’t worry! They’re incredibly useful tools once you understand the basics, from inflating your car tires to running that nail gun you’ve been eyeing. We’re going to walk through everything, step-by-step, making it simple and straightforward. Get ready to tackle those tasks with a newfound ease!

Choosing the Right Air Compressor for Your Needs

Before we dive into how to use an air compressor, let’s briefly touch on choosing one, as the right compressor makes all the difference. Think about what you want to do with it.

- Inflating Tires & Balls: Most small, portable compressors will handle this easily.

- Powering Air Tools (Nailers, Staplers): You’ll need a compressor with a higher CFM (Cubic Feet per Minute) rating and a larger tank.

- Painting (Spray Guns): This often requires a compressor with a consistent air supply and good CFM output.

- Home Maintenance (Cleaning, Air Duster): Smaller units are usually sufficient.

Consider the tank size (gallons) and the CFM output. Higher CFM means more air power, which is crucial for tools that need a constant supply.

Understanding the Basic Components of an Air Compressor

Let’s get familiar with the parts you’ll be interacting with. Knowing these will make the “how-to” much clearer.

- Tank: Stores the compressed air.

- Motor/Engine: Powers the pump to compress air.

- Pump: Compresses the air and fills the tank.

- Pressure Gauge: Shows the air pressure inside the tank.

- Regulator: Adjusts the output air pressure to a specific level for your tools.

- Drain Valve: Located at the bottom of the tank to release moisture.

- On/Off Switch: Powers the compressor.

- Air Outlet/Coupler: Where you connect your air hose.

- Safety Relief Valve: Releases excess pressure if the tank pressure gets too high.

Knowing these parts will help you understand the operation and maintenance steps later on.

Step-by-Step Guide: How to Use an Air Compressor

Now, for the main event! Using an air compressor is straightforward once you follow these steps.

Step 1: Safety First!

Always prioritize safety. Air compressors store air under high pressure, so understanding safety precautions is crucial.

- Read your compressor’s manual thoroughly.

- Ensure the compressor is on a stable, level surface.

- Wear safety glasses to protect your eyes from debris or escaping air.

- Never point an air tool or hose at yourself or others.

- Ensure the area is well-ventilated, especially if using the compressor indoors for tasks like painting.

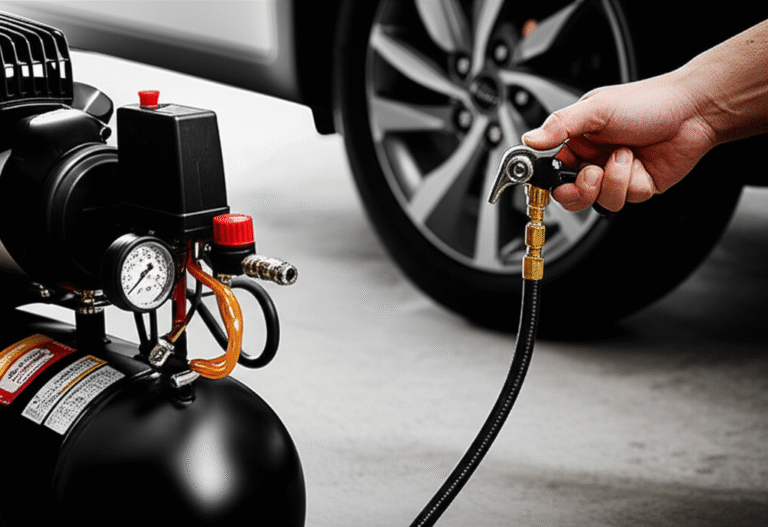

Step 2: Connect the Air Hose and Tools

This is where you connect your air-powered tools.

- Select the Right Hose: Use an air hose rated for the pressure your compressor and tools will generate.

- Connect the Hose to the Compressor: Push the coupler on the end of your air hose firmly onto the air outlet on the compressor. You should hear a click as it locks into place.

- Connect Your Tool: Attach your air tool (e.g., nail gun, tire inflator) to the other end of the air hose using the appropriate fitting.

Step 3: Turn On and Fill the Tank

It’s time to let the compressor do its work.

- Check the Drain Valve: Ensure the drain valve at the bottom of the tank is closed. If it’s open, air will escape.

- Plug In and Turn On: Plug the compressor into a suitable power outlet and flip the On/Off switch.

- Listen and Watch: The motor will start, and the compressor will begin filling the tank with air. You’ll hear it working. The pressure gauge will indicate the pressure building up.

- Automatic Shut-Off: Most compressors have an automatic shut-off. When the tank reaches its maximum pressure, the motor will stop by itself.

Step 4: Set the Regulator

This step is vital for protecting your tools and ensuring proper operation.

- Locate the Regulator: You’ll find the regulator, often with a dial or knob, near the air outlet.

- Consult Your Tool’s Manual: Check the operating pressure requirements for the specific air tool you are using. This is crucial for tool longevity and performance.

- Adjust the Pressure: Slowly turn the regulator knob. One direction increases pressure, and the other decreases it. Watch the secondary pressure gauge (the one after the regulator) as you adjust. Set it to the recommended PSI (Pounds per Square Inch) for your tool.

Here’s a quick reference for common tool pressures:

| Air Tool | Typical Operating Pressure (PSI) |

|---|---|

| Tire Inflator | 30-50 PSI |

| Brad Nailer | 70-100 PSI |

| Framing Nailer | 90-120 PSI |

| Impact Wrench | 90-130 PSI |

| Spray Gun (HVLP) | 20-50 PSI (tool specific) |

| Air Sander | 90-100 PSI |

Note: Always refer to your specific tool’s manufacturer for exact pressure requirements.

Step 5: Operate Your Air Tool

With the compressor running and the regulator set, you’re ready to use your tool.

- Engage the Tool: Follow the instructions for your specific air tool. Most tools have a trigger or lever to activate the air flow.

- Monitor Pressure: Keep an eye on the regulator gauge and the tank pressure gauge. If the tank pressure drops too low, the compressor may kick on again to refill it.

- Work Efficiently: Use the tool as needed. If you’re using a tool that requires a continuous airflow, ensure your compressor’s CFM output is sufficient for the task.

Step 6: Turn Off and Drain the Compressor

Proper shutdown is important for maintenance and safety.

- Release Tool Pressure: Disconnect your air tool from the hose or release any trigger pressure.

- Turn Off the Compressor: Flip the On/Off switch to the Off position.

- Disconnect the Hose: If you’re finished using the compressor, disconnect the air hose from the compressor’s outlet.

- Drain the Tank: This is a critical maintenance step. Open the drain valve at the bottom of the tank. You’ll hear the remaining air and see any collected water drain out. Leave it open for a few minutes to ensure all moisture is removed. This prevents rust and corrosion inside the tank.

Essential Maintenance for Longevity

To keep your air compressor in top shape, a little regular maintenance goes a long way.

- Drain the Tank Daily: As mentioned, this is the most important maintenance step. Water accumulation can cause rust and damage the tank.

- Check the Oil Level (for oil-lubricated models): If you have an oil-lubricated compressor, check the oil level regularly and top it up or change it according to the manufacturer’s recommendations. Oil-free compressors don’t have this step.

- Clean the Air Filter: A clogged air filter restricts airflow and reduces performance. Check and clean or replace it periodically, depending on how often you use the compressor and the dustiness of your environment. You can usually find the filter near the pump intake.

- Inspect Hoses and Fittings: Look for any cracks, leaks, or damage in your air hoses and fittings. Replace them if they show signs of wear.

- Check the Safety Relief Valve: Periodically pull the ring on the safety relief valve to ensure it operates freely and isn’t stuck. This is a critical safety component.

Proper maintenance can significantly extend the life of your air compressor and ensure it performs reliably. For more in-depth maintenance guides, resources like OSHA’s guidelines on compressed gas safety offer valuable insights into handling pressurized systems safely.

Troubleshooting Common Air Compressor Issues

Even with the best care, you might run into small hiccups. Here are a few common issues and simple solutions:

- Compressor Not Starting: Check if it’s plugged in, the circuit breaker hasn’t tripped, and the motor isn’t overheating.

- Compressor Not Building Pressure: Ensure the drain valve is closed, check for air leaks in hoses or connections, and make sure the air filter isn’t blocked.

- Air Leaks: Listen for hissing sounds. Check all connections, hoses, and fittings. Tighten loose connections or replace damaged parts.

- Tool Not Performing Well: Verify the regulator is set correctly for the tool, check the tank pressure, and ensure the compressor’s CFM output is adequate for the tool’s demand.

Frequently Asked Questions About Using Air Compressors

Let’s answer some common questions beginners have.

What does CFM mean on an air compressor?

CFM stands for Cubic Feet per Minute. It measures the volume of air the compressor can deliver at a specific pressure. Tools have CFM requirements, and your compressor needs to meet or exceed them for proper operation.

Can I use an air compressor indoors?

It depends on the type. Electric compressors are generally safe for indoor use in well-ventilated areas. However, gasoline-powered compressors produce exhaust fumes and should NEVER be used indoors due to the risk of carbon monoxide poisoning. Always ensure adequate ventilation, especially if painting or using solvents.

How do I know if my air compressor is building enough pressure?

You can check the pressure using the gauges on the compressor. There’s usually a large gauge showing the tank pressure and a smaller one showing the regulated output pressure. Compare these to the recommended PSI for your tools and the compressor’s specifications.

Why is there water coming out of my air compressor tank?

This is completely normal! Air contains moisture. When the air is compressed, the moisture condenses into water. This is why draining the tank regularly is crucial to prevent internal rust and damage.

How often should I drain my air compressor tank?

You should drain your air compressor tank after every use. This is the most effective way to remove accumulated moisture and prevent internal corrosion.

What happens if I over-pressurize my air tool?

Over-pressurizing an air tool can damage it, cause it to malfunction, or even lead to a dangerous failure. Always set your regulator to the manufacturer’s recommended PSI for the specific tool you are using.

Conclusion

So there you have it! Using an air compressor doesn’t have to be intimidating. By understanding the basic parts, following the simple steps for operation, prioritizing safety, and performing a little bit of regular maintenance, you can confidently tackle a wide range of projects. Whether you’re inflating tires, powering up your favorite air tools, or getting ready for a painting project, your air compressor is a versatile ally. Remember to always consult your manuals, wear your safety gear, and enjoy the power and efficiency that compressed air brings to your DIY adventures! Happy building!