A central air compressor is a powerful machine that stores compressed air to operate pneumatic tools, inflate items, and more. It’s a common setup in workshops and garages, offering consistent air pressure for various tasks.

Navigating the world of air compressors can feel a bit like deciphering a secret code, especially when you’re just starting out. You might hear terms like “central air compressor” and wonder what makes it different, or if it’s even something you need. It’s a common question, and honestly, it can be a bit confusing with all the different types and sizes out there. But don’t worry, I’m here to break it all down for you in a way that makes perfect sense. Think of this as your friendly guide to understanding what a central air compressor is, how it works, and whether it’s the right fit for your home or workshop. We’ll cover everything from its core function to how to choose and care for one, so you can tackle your projects with confidence.

What Exactly is a Central Air Compressor?

So, let’s get down to brass tacks: what is a central air compressor? At its heart, a central air compressor is a system designed to compress air and store it in a tank. This stored, compressed air then acts as a power source for a variety of pneumatic tools and applications. Unlike portable compressors that you might carry around for small tasks, a central air compressor is typically larger, more powerful, and often stationary or semi-permanent. It’s the kind of workhorse you’d find in a professional auto shop, a woodworking studio, or a manufacturing facility, but there’s no reason a dedicated DIYer or homeowner can’t benefit from one too.

The “central” part of the name refers to its function within a larger system. Instead of being a standalone unit for one specific task, it serves as a central hub, supplying air to multiple tools or workstations, often through a network of hoses and fittings. This makes it incredibly efficient for environments where compressed air is needed frequently and for demanding applications.

How Does a Central Air Compressor Work?

The magic of an air compressor lies in its ability to take atmospheric air and squeeze it into a smaller volume, thereby increasing its pressure. Here’s a simplified breakdown of how it works:

- Intake: The compressor draws in ambient air through an intake filter, which removes dust and debris.

- Compression: This is where the main action happens. A motor (electric or gas-powered) drives a mechanism – usually a piston inside a cylinder, similar to an engine – that compresses the air. As the piston moves down, it draws air in; as it moves up, it forces that air into a smaller space, increasing its pressure.

- Storage: The compressed air is then directed into a storage tank, which is essentially a pressure vessel. This tank holds a reserve of compressed air, allowing the compressor to cycle on and off as needed, rather than running continuously.

- Regulation: Pressure regulators are used to control the amount of air pressure released from the tank to the tools. This is crucial because different tools require different pressure levels to operate correctly and safely.

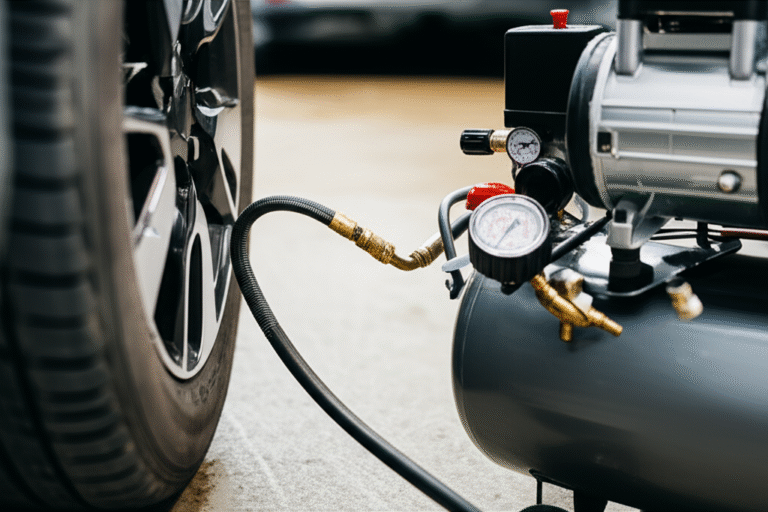

- Output: Hoses connect the tank to your tools, delivering the regulated, compressed air when you pull the trigger or activate the tool.

The entire process is managed by a pressure switch. When the pressure in the tank drops below a certain level, the switch turns the motor on to re-compress the air. When the tank reaches its maximum pressure, the switch turns the motor off. This cycle ensures you always have pressurized air available without overworking the compressor.

Key Components of a Central Air Compressor System

Understanding the individual parts can demystify the whole setup. A central air compressor system isn’t just the compressor itself; it’s a collection of components working together to deliver reliable power.

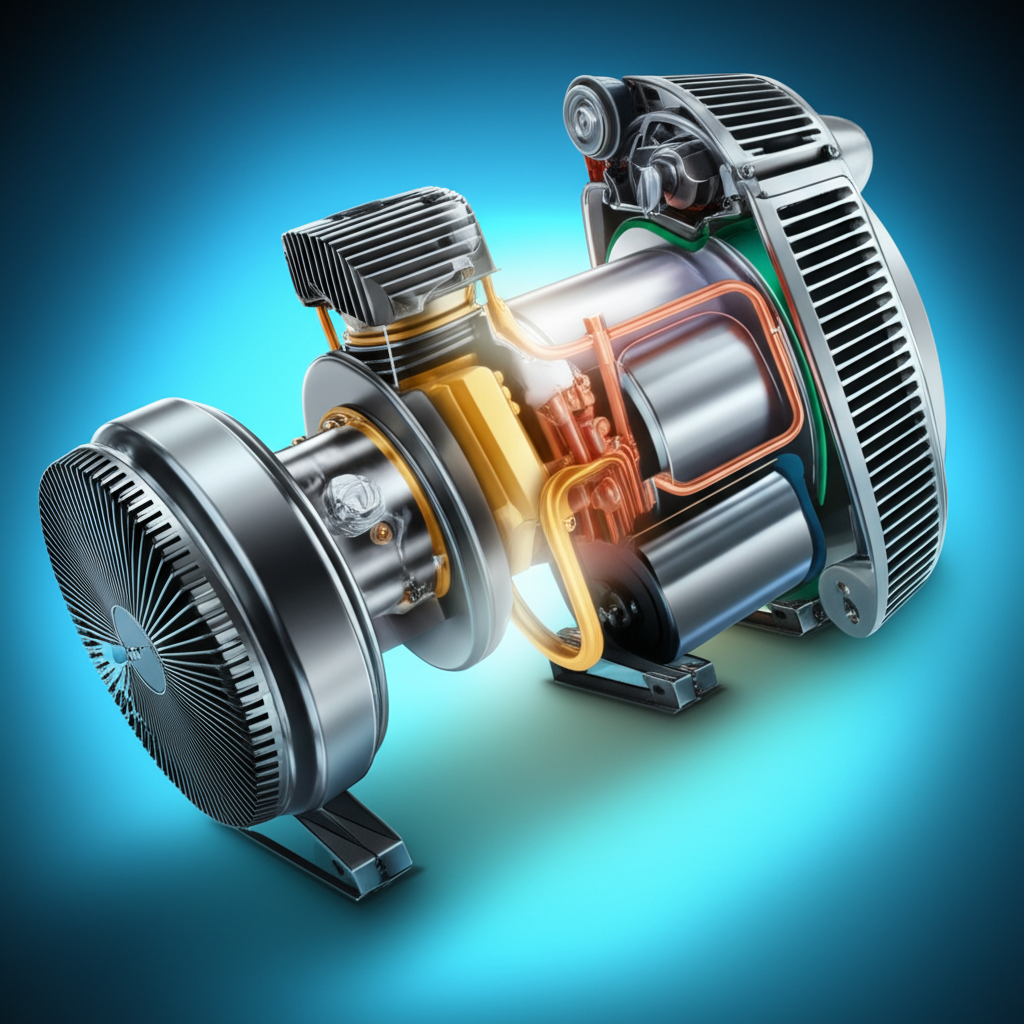

- The Compressor Unit: This is the heart of the system, containing the motor, pump (piston, screw, or rotary vane), and often the cooling system.

- The Air Tank: Also known as a receiver tank, this is where the compressed air is stored. Tanks come in various sizes, measured in gallons. A larger tank provides a more consistent air supply and allows the compressor motor to run less frequently.

- Pressure Switch: This automatic switch controls the operation of the motor, turning it on when tank pressure is low and off when it reaches the set maximum.

- Pressure Gauge(s): These display the current pressure inside the tank and the regulated output pressure.

- Safety Relief Valve: A crucial safety feature that automatically releases excess pressure if the pressure switch malfunctions, preventing the tank from rupturing.

- Drain Valve: Located at the bottom of the tank, this is used to drain out moisture and oil that condense during the compression process. Regular draining is vital for preventing rust and tank damage.

- Air Filter(s): Essential for quality air. They clean the intake air and can also be placed downstream to filter the air going to your tools.

- Regulator: This device reduces the high pressure from the tank to a lower, usable pressure for your tools.

- Lubricator (optional but recommended): Adds a fine mist of oil to the air stream to lubricate pneumatic tools, extending their life.

- Air Hoses and Fittings: These connect the compressor system to your tools and are sized according to the air volume needed.

Types of Central Air Compressors

While the core function is the same, central air compressors can differ in how they compress air and their overall design. For home and workshop use, you’ll primarily encounter two types:

1. Reciprocating (Piston) Air Compressors

These are the most common type for workshops and garages. They work much like a car engine, using pistons that move up and down inside cylinders to compress air.

- Single-Stage: Compresses air in one stroke of the piston. These are generally less powerful and suitable for lighter-duty tools like nail guns or impact wrenches for occasional use.

- Two-Stage: Compresses air in two stages. The air is compressed once, then cooled, and then compressed again. This results in higher pressure and a more consistent air supply, making them ideal for more demanding tools like sanders, grinders, and spray guns.

Pros of Reciprocating Compressors:

- Widely available and generally more affordable than rotary screw compressors.

- Good for intermittent use and a variety of DIY projects.

- Relatively simple to maintain for the most part.

Cons of Reciprocating Compressors:

- Can be noisy.

- May produce more heat.

- Less efficient for continuous, heavy-duty industrial use compared to rotary screw.

2. Rotary Screw Air Compressors

These are less common in home garages but are the standard for industrial and commercial applications. They use two interlocking helical screws to compress air as it’s drawn into the unit.

Pros of Rotary Screw Compressors:

- Much quieter operation than piston compressors.

- Designed for continuous duty and high-volume air delivery.

- More energy-efficient for heavy, constant use.

- Produce less vibration.

Cons of Rotary Screw Compressors:

- Significantly more expensive upfront.

- More complex maintenance, often requiring specialized service.

- Typically overkill for most home workshop needs unless you have very specific, high-demand requirements.

For most DIYers and homeowners looking for a robust compressed air solution, a two-stage reciprocating air compressor is usually the sweet spot.

What Can You Do with a Central Air Compressor?

The versatility of compressed air is what makes a central compressor so valuable. Here are just a few of the many tasks it can power:

- Powering Pneumatic Tools: This is the most common use. Think impact wrenches for changing tires, nail guns and staple guns for woodworking and upholstery, air ratchets for tight spots, and sanders or grinders for automotive work and metal fabrication.

- Inflating Tires and Sporting Goods: Quickly and easily inflate car tires, bicycle tires, sports balls, and inflatable toys.

- Painting and Spraying: Achieve a smooth, professional finish with spray guns for automotive paints, lacquers, or even house paint. Compressed air atomizes the paint for an even coat.

- Cleaning and Blowing: Use an air blower nozzle to clear away dust, debris, and sawdust from work surfaces, tools, and machinery.

- Air Brushing: For intricate detailing in art, crafts, or model building.

- Tire Balancing and Alignment Equipment: In professional settings, larger compressors power specialized automotive shop equipment.

The type of tool you plan to use will heavily influence the size and specifications of the compressor you need.

Choosing the Right Central Air Compressor: Key Considerations

Selecting the right compressor is crucial to avoid frustration and ensure your tools run efficiently. Don’t just grab the biggest one you see! Here’s what to think about:

1. Horsepower (HP)

Horsepower indicates the power of the motor driving the compressor pump. More HP generally means more air output. For home use, 2 HP to 5 HP is common.

2. Cubic Feet per Minute (CFM)

This is arguably the MOST important specification. CFM measures the volume of air the compressor can deliver at a specific pressure (usually 90 PSI). Your tools have CFM requirements. If your compressor doesn’t meet the CFM demand of your tools, they won’t perform correctly, or the compressor will run constantly, leading to overheating and premature wear.

How to determine your CFM needs:

- Check your tools: Most pneumatic tools will list their CFM requirement at a specific PSI.

- Add up the requirements: If you plan to run multiple tools simultaneously, add their CFM requirements together.

- Add a buffer: It’s wise to choose a compressor that provides at least 20-50% more CFM than your highest single tool’s requirement, or your combined total if running multiple. This ensures the compressor isn’t constantly struggling.

3. Tank Size (Gallons)

Tank size determines how long you can run a tool before the compressor motor needs to cycle back on. A larger tank provides a more consistent air supply and allows the motor to cool down between cycles.

- Small tanks (under 30 gallons): Suitable for light-duty, intermittent use (e.g., occasional nailing, tire inflation).

- Medium tanks (30-60 gallons): Good for moderate use, running impact wrenches, small grinders, or paint sprayers for short periods.

- Large tanks (60+ gallons): Recommended for continuous use, running multiple tools, or demanding tools like sanders or large impact wrenches.

4. Pressure (PSI)

Most tools operate between 70-100 PSI. Air compressors are rated for maximum tank pressure, often 125-175 PSI. Ensure the compressor can deliver the required PSI for your tools and that it has a reliable regulator to adjust this down.

5. Duty Cycle

This refers to how long a compressor can run before needing to cool down.

- Intermittent Duty: Designed for short bursts of operation.

- Continuous Duty (or 75%-100% Duty Cycle): Can run for long periods without overheating. Two-stage piston compressors and rotary screw compressors typically have higher duty cycles. For a central compressor, aim for at least a 50% duty cycle, ideally higher if you’ll be using it extensively.

6. Power Source (Electric vs. Gas)

Electric: Most common for home and workshop use. They are quieter, cleaner, and don’t produce exhaust fumes, so they are suitable for indoor use. You’ll need an appropriate electrical outlet (often 240V for larger units).

Gas: More portable and powerful, ideal for outdoor use or areas without easy electrical access. However, they are louder, produce exhaust, and require more ventilation.

7. Noise Level

Air compressors can be LOUD. If noise is a concern, look for models specifically designed for quiet operation or consider soundproofing solutions for your compressor area.

Air Compressor Specifications Comparison Table

To help visualize, let’s compare a couple of common scenarios.

| Feature | Light DIYer (Nail Gun, Tire Inflation) | Intermediate Hobbyist (Impact Wrench, Painting) | Professional/Heavy Duty (Sanders, Grinders) |

| :—————– | :————————————- | :———————————————— | :——————————————- |

| HP | 1.5 – 2.5 HP | 3 – 5 HP | 5+ HP |

| CFM @ 90 PSI | 4 – 6 CFM | 7 – 12 CFM | 12+ CFM |

| Tank Size | 20 – 30 Gallons | 30 – 60 Gallons | 60+ Gallons |

| Stage | Single-stage or Two-stage | Two-stage | Two-stage |

| Duty Cycle | 50% | 75% or higher | 100% |

| Power Type | Electric (120V or 240V) | Electric (240V) | Electric (240V) or Gas |

Remember, these are general guidelines. Always check the specific requirements of your tools!

Installation and Setup

Once you’ve chosen your compressor, proper setup is key for performance and longevity.

- Location: Place the compressor on a firm, level surface. Ensure there’s adequate ventilation around it for cooling. Avoid placing it in excessively dusty or humid environments. For electric units, make sure it’s near a suitable power outlet.

- Electrical Connections: Larger compressors often require a 240V circuit. If you’re not comfortable with electrical work, hire a qualified electrician. Incorrect wiring can be dangerous and damage the compressor. For safety regulations and best practices, consult resources like the Occupational Safety and Health Administration (OSHA) standards for compressed gas and air systems.

- Air Lines: Run air hoses from the compressor tank to your work areas. Use appropriately sized hoses and fittings to prevent air leaks and pressure drops. Consider installing a manifold system with quick-connect couplers at various points in your workshop.

- Initial Startup: Before running the compressor, double-check that all connections are secure and that lubricants are at the correct level (if applicable). Follow the manufacturer’s startup instructions carefully.

Maintenance: Keeping Your Compressor in Top Shape

Regular maintenance is crucial for ensuring your central air compressor runs efficiently and lasts a long time. Neglecting it can lead to costly repairs or premature failure.

Daily/Weekly Maintenance:

- Drain the Tank: This is the most important daily task. Open the drain valve at the bottom of the tank to release any accumulated moisture. Water in the tank can cause rust and corrosion, weakening the tank over time and potentially leading to a rupture.

- Check Oil Level (if applicable): For oiled compressors, check the oil level and top it up if necessary before each use. Use only the manufacturer-recommended type of oil.

- Inspect Air Filter: Ensure the intake air filter is clean. A clogged filter restricts airflow, reducing performance and straining the motor. Clean or replace it as needed.

Monthly Maintenance:

- Clean the Intake Filter: A more thorough cleaning or replacement of the air intake filter.

- Check Belts (for belt-driven compressors): Ensure the drive belt is properly tensioned and not showing signs of wear. A loose or worn belt can slip, reducing efficiency and potentially breaking.

- Inspect Hoses and Fittings: Look for any leaks, cracks, or damage in air hoses and connections. Leaks waste air and energy.

Annual/As-Needed Maintenance:

- Change Oil: For oiled compressors, change the oil annually or according to the manufacturer’s recommendations.

- Clean or Replace Intercoolers/Aftercoolers: If your compressor has these components, they may need cleaning to maintain cooling efficiency.

- Service the Pressure Switch and Safety Valve: Ensure these critical components are functioning correctly. They are vital for safe operation.

Always refer to your compressor’s owner’s manual for specific maintenance schedules and procedures.

FAQs About Central Air Compressors

- What PSI should I set my compressor regulator to?

- This depends entirely on the tools you are using. Most pneumatic tools will list their operating pressure requirement, usually between 70-100 PSI. Always check your tool’s manual and set the regulator accordingly.

- Can I run a central air compressor indoors?

- Electric compressors can be run indoors, provided there is adequate ventilation for cooling. Gas-powered compressors should NEVER be run indoors due to dangerous exhaust fumes (carbon monoxide). Always ensure proper safety precautions and ventilation.

- How do I know if my compressor is too small for my tools?

- If your compressor