Concrete drilling can be effectively powered by air compressors, offering a dust-free and efficient method when using specialized pneumatic drilling equipment, particularly for smaller, less demanding jobs.

Concrete drilling. It sounds like a big, dusty job, right? And often, it is! But what if I told you that your trusty air compressor, the one you might use for inflating tires or powering a nail gun, could actually be a powerful ally in concrete drilling? Many DIYers and homeowners shy away from concrete work because of the mess and the specialized tools required. But with the right setup and a little know-how, you might be surprised at what’s possible. This guide will break down how air compressors can be used for drilling concrete, focusing on the practicalities and the proven methods that make it a cleaner, more efficient option. We’ll cover everything from understanding the equipment to getting the job done safely and effectively.

Understanding the Air Compressor’s Role in Concrete Drilling

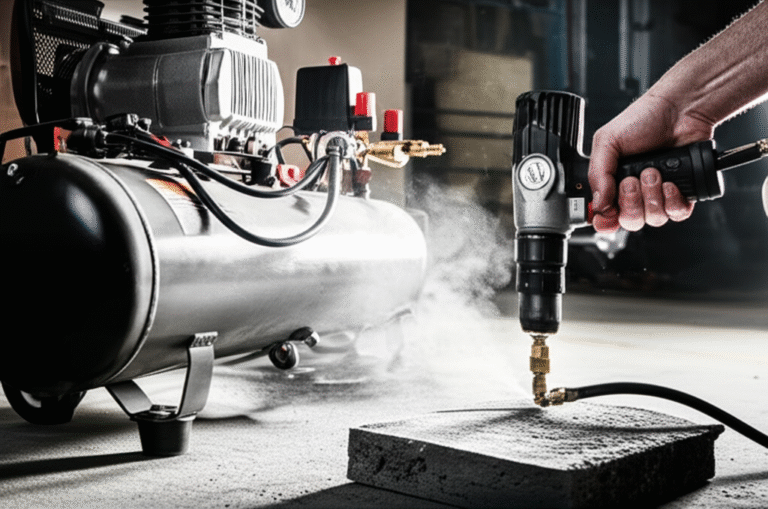

When we talk about air compressors and concrete drilling, it’s important to clarify that a standard air compressor itself doesn’t directly drill concrete. Instead, it provides the compressed air needed to power specialized pneumatic tools designed for this very task. Think of the air compressor as the engine and the pneumatic drill as the car. Without the engine, the car doesn’t go anywhere.

The magic of using compressed air for concrete drilling lies in its ability to provide consistent power and, crucially, to facilitate dust collection. Unlike electric hammer drills or rotary hammers that generate a lot of airborne dust, pneumatic drills often integrate a dust extraction system powered by the same air compressor. This is a game-changer for indoor projects or when working in sensitive environments.

How Does an Air Compressor Work?

Before we dive into how it helps with concrete drilling, let’s quickly touch on how an air compressor works. At its core, an air compressor is a device that takes in ambient air and compresses it into a smaller volume, storing this pressurized air in a tank. This is typically achieved through a piston mechanism, similar to an internal combustion engine, but instead of generating power through explosions, it’s simply pushing air.

1. Intake: Air is drawn into the cylinder through an intake valve.

2. Compression: A piston moves up, reducing the volume of the air and increasing its pressure.

3. Discharge: The compressed air is then forced out of the cylinder through a discharge valve into the air tank.

4. Storage: The tank stores this compressed air at a regulated pressure, ready to be delivered to a tool via a hose.

This stored, pressurized air is the “power” that drives pneumatic tools. For concrete drilling, this means powering the hammering action and rotation of a pneumatic drill, as well as often operating an integrated dust collection system.

Pneumatic Drilling vs. Traditional Methods

When you’re faced with drilling into concrete, you likely think of electric rotary hammers or hammer drills. These are excellent tools, but they have their drawbacks, especially concerning dust and sometimes vibration. Pneumatic drilling, powered by an air compressor, offers a compelling alternative.

Here’s a quick comparison:

| Feature | Pneumatic Concrete Drill (Air-Powered) | Electric Rotary Hammer/Hammer Drill |

| :—————- | :——————————————————————- | :——————————————————————– |

| Power Source | Compressed air from an air compressor | Electricity (corded or battery) |

| Dust Control | Often features integrated dust collection, greatly reducing airborne dust. | Generates significant dust; requires separate dust extraction or vacuum. |

| Power Delivery| Consistent, high torque. Can be adjusted by compressor settings. | Variable, can sometimes be less consistent under heavy load. |

| Vibration | Generally lower vibration, leading to less user fatigue. | Can produce significant vibration. |

| Tool Weight | Can be lighter as the motor is in the compressor, not the tool itself. | Varies, but the motor is in the tool, adding weight. |

| Maintenance | Requires air compressor maintenance (oil, filters). Tool is simpler. | Requires tool maintenance (brushes, gears). |

| Ideal Use | Finer work, indoor jobs, situations where dust is a major concern. | Heavy-duty, continuous drilling, outdoor work. |

The primary advantage of pneumatic drilling for concrete often boils down to dust control. The U.S. Occupational Safety and Health Administration (OSHA) emphasizes the importance of controlling silica dust, which is a serious health hazard present in concrete. Pneumatic systems with integrated dust collection are a highly effective way to mitigate this risk. For more on OSHA’s silica dust standards, you can visit their Silica page.

Essential Equipment for Pneumatic Concrete Drilling

To get started with drilling concrete using an air compressor, you’ll need a few key pieces of equipment. It’s not just about having an air compressor; the quality and type of pneumatic drill and accessories matter significantly.

1. The Right Air Compressor

This is your foundation. Not all air compressors are created equal when it comes to powering demanding tools like concrete drills.

CFM (Cubic Feet per Minute): This is the most critical factor. Your air compressor needs to supply enough CFM at a specific PSI (pounds per square inch) to keep the pneumatic drill running effectively. Check the specifications of the pneumatic drill you intend to use. It will state its CFM requirement. Your compressor’s output CFM at the required PSI should meet or exceed this.

Tank Size: A larger tank provides a buffer of compressed air, meaning the compressor motor won’t have to cycle on and off as frequently. This is beneficial for sustained drilling.

Horsepower (HP) and PSI: While CFM is king, higher HP generally correlates to higher CFM output. The PSI rating indicates the maximum pressure the compressor can deliver. Most pneumatic tools operate in the 90-100 PSI range.

Type of Compressor: For DIY and occasional use, an oil-lubricated, single-stage or two-stage reciprocating compressor is common. For more demanding or continuous use, a rotary screw compressor might be considered, but this is usually overkill for typical homeowner projects.

Pro Tip: When choosing a compressor, it’s always better to have a little extra CFM capacity than not enough. An undersized compressor will struggle, leading to inefficient drilling and potentially damaging the tool or compressor.

2. The Pneumatic Concrete Drill

This is your workhorse. Pneumatic concrete drills come in various forms, but for drilling, you’ll typically be looking for a rotary hammer or a heavy-duty hammer drill specifically designed for air power.

Rotary Hammers: These are designed for drilling into hard materials like concrete. They combine rotation with a hammering action to chip away at the material.

Hammer Drills: These also rotate and hammer, but the hammering action is often less forceful than a dedicated rotary hammer. They are suitable for lighter concrete drilling tasks.

Key features to look for in a pneumatic drill:

Chuck Type: SDS-plus or SDS-max chucks are standard for concrete drilling, designed to handle the hammering action.

Variable Speed and Hammering Control: Allows you to adjust the tool’s performance based on the concrete type and the desired hole size.

Integrated Dust Collection: As mentioned, this is a huge benefit. Look for models with a shroud that connects to a separate vacuum or dust port.

3. Air Hoses and Fittings

Air Hose: Use a high-quality air hose rated for the PSI your compressor and tool require. The diameter of the hose also affects airflow; a larger diameter (e.g., 3/8″ or 1/2″) is generally better for tools that require significant CFM.

Fittings: Ensure you have the correct quick-connect fittings for your compressor and tool.

Air Filter/Regulator/Lubricator (FRL Unit): This is highly recommended for pneumatic tools.

Filter: Removes moisture and debris from the air, protecting your tool.

Regulator: Allows you to set and maintain the correct operating pressure for your tool.

Lubricator: Feeds a small amount of oil into the air stream to keep internal tool parts lubricated, especially important for tools with hammering mechanisms.

4. Drill Bits

You’ll need masonry drill bits specifically designed for concrete.

Carbide-Tipped Bits: These are standard for drilling concrete.

SDS Bits: If your pneumatic drill has an SDS chuck, you’ll need SDS-shank bits.

Appropriate Size: Choose bits that match the diameter and depth of the holes you need to drill.

5. Safety Gear

Safety Glasses: Essential to protect your eyes from flying debris.

Hearing Protection: Air compressors and pneumatic tools can be loud.

Dust Mask/Respirator: Even with dust collection, it’s wise to wear a mask, especially when dealing with silica dust.

Work Gloves: For grip and protection.

Step-by-Step: Drilling Concrete with a Pneumatic Drill

Now that you have your equipment, let’s walk through the process. Safety first, always!

Step 1: Prepare Your Workspace and Safety Gear

Clear the Area: Remove any obstructions, furniture, or items that could be in the way or damaged by dust or debris.

Ventilation: Ensure good ventilation, especially if working indoors.

Don Your Safety Gear: Put on your safety glasses, hearing protection, gloves, and dust mask/respirator.

Step 2: Set Up the Air Compressor

1. Placement: Position the air compressor on a stable, level surface, ideally away from the immediate work area to minimize noise. Ensure it has adequate ventilation.

2. Connect Power: Plug the compressor into a suitable electrical outlet.

3. Check Oil Levels: If your compressor requires oil, ensure the level is correct.

4. Turn On and Charge: Turn on the compressor and let it build up pressure. Allow it to reach its maximum pressure or the desired working pressure.

Step 3: Connect the Air System

1. Attach FRL: Connect the FRL unit to the compressor’s outlet.

2. Connect Air Hose: Attach the air hose to the FRL unit.

3. Connect Tool: Connect the other end of the air hose to your pneumatic concrete drill. Ensure the connection is secure.

Step 4: Set the Air Pressure

1. Check Tool Specs: Refer to your pneumatic drill’s manual for the recommended operating pressure. This is typically around 90-100 PSI.

2. Adjust Regulator: Use the regulator knob on your FRL unit to set the pressure to the recommended level. You can usually see the pressure gauge on the FRL unit.

Step 5: Install the Drill Bit

1. Insert Bit: Ensure the compressor is running at the correct pressure but not actively powering the drill (i.e., the trigger is not pulled). Insert the appropriate masonry bit into the chuck.

2. Secure Chuck: Engage the chuck mechanism according to your tool’s design (e.g., SDS lock).

Step 6: Position for Drilling

1. Mark Your Spot: Use a pencil or marker to indicate where you need to drill the hole.

2. Start the Hole: Place the tip of the drill bit precisely on your mark.

3. Engage Dust Collection: If your tool has integrated dust collection, ensure it’s properly seated against the concrete surface to create a seal. If you’re using an external vacuum, ensure it’s connected and running.

Step 7: Drill the Concrete

1. Apply Light Pressure: Gently press the drill against the concrete.

2. Pull the Trigger: Slowly pull the trigger on the pneumatic drill.

3. Maintain Pressure: Apply steady, even pressure. Let the tool do the work. Don’t force it.

4. Control Depth: If you need a specific depth, use a depth stop on your drill or mark the bit with tape.

5. Clear Debris: Periodically, you might need to pull the drill bit out slightly (while the drill is still running) to clear accumulated dust and debris from the hole, especially if your dust collection isn’t perfect. The hammering action combined with rotation helps with this.

6. Listen and Feel: Pay attention to the sound and feel of the drill. If it sounds strained or the hammering seems to stop, you might be pushing too hard, or your compressor’s CFM might be insufficient for the task.

Step 8: Finishing Up

1. Release Trigger: Once the hole is drilled to the desired depth, release the trigger.

2. Remove Drill Bit: Carefully withdraw the drill bit from the hole.

3. Turn Off: Turn off the pneumatic drill, then turn off the air compressor.

4. Disconnect: Disconnect the air hose from the tool and the compressor.

5. Clean Up: Clean your tools and the work area. Dispose of any dust collected in the dust port or vacuum bag.

Maintaining Your Pneumatic Drilling Setup

Proper maintenance ensures your air compressor and pneumatic tools last longer and perform better.

Air Compressor Maintenance

Drain the Tank: Regularly drain any moisture from the air tank. Water can cause rust and damage the tank and your tools. Many compressors have a drain valve at the bottom.

Check Oil Levels: For oil-lubricated compressors, check the oil level regularly and change it according to the manufacturer’s recommendations.

Clean/Replace Air Filters: Clogged air intake filters reduce compressor efficiency. Clean or replace them as needed.

Inspect Hoses and Fittings: Check for leaks or damage.

Pneumatic Tool Maintenance

Lubrication: Use an FRL unit with a lubricator, or manually lubricate the tool according to the manufacturer’s instructions.

Cleanliness: Keep the tool clean, especially the chuck and exhaust ports.

Storage: Store pneumatic tools in a clean, dry place.

Troubleshooting Common Issues

Even with the best setup, you might encounter a few hiccups.

| Problem | Potential Cause | Solution |

| :————————————– | :————————————————————————— | :—————————————————————————————————————————————————————————————————————————————————————————————————————————————————————– |

| Drill not hammering or rotating | Low air pressure; clogged air filter; tool lubrication issue; internal damage. | Check compressor pressure and ensure it’s set correctly. Inspect and clean/replace air filters. Ensure the FRL lubricator is functioning. If the issue persists, the tool may need professional servicing. |

| Weak drilling performance | Air compressor CFM too low for the tool; leaky air hose or fittings; low tank pressure. | Ensure your compressor meets the tool’s CFM requirements. Check all air hose connections for leaks and tighten or replace fittings if necessary. Ensure the compressor is fully charged. |

| Excessive dust | Poor seal on dust collection shroud; dust collection hose blocked; vacuum not powerful enough. | Ensure the dust collection shroud is properly seated against the concrete. Check for blockages in the dust collection hose. If using an external vacuum, ensure it’s adequate for the amount of dust being generated. You may need a higher-CFM compressor to power both the drill and an integrated dust collection system efficiently. |

| Compressor cycling too frequently | Air leaks in the system; CFM demand is too high for the compressor’s output; pressure switch issue. | Check all pneumatic connections for leaks. Ensure your compressor’s CFM output is sufficient for the tool’s demand. If none of the above, consult your compressor manual or a service technician. |

| Tool vibrating excessively | Damaged drill bit; tool internal wear; improper technique. | Inspect the drill bit for damage or bends. Ensure the tool is properly lubricated. Try adjusting your grip and pressure. If vibration is extreme and consistent, the tool may require servicing. |

When to Call a Professional

While pneumatic tools can make concrete drilling more manageable, it’s important to recognize their limitations and your own.

Very Large or Deep Holes: For large diameter holes or drilling very deep into reinforced concrete, heavy-duty electric rotary hammers or specialized concrete drilling services are often more appropriate and efficient.

Heavy-Duty, Repetitive Work: If you’re performing extensive concrete drilling as part of a professional trade or a very large DIY project, investing in dedicated electric or even hydraulic drilling equipment might be more suitable.

Uncertainty or Safety Concerns: If you’re ever unsure about a step, the equipment, or the safety aspects of the job, it’s always best to consult a professional contractor or experienced tradesperson. They can provide guidance or handle the task for you.

Frequently Asked Questions (FAQ)

Q1: Can any air compressor power a pneumatic concrete drill?

A1: Not necessarily. The air compressor must have a sufficient Cubic Feet per Minute (CFM) output rating at the required PSI to operate the specific pneumatic drill. Always check the tool’s specifications and match them to your compressor’s capabilities.

Q2: Is pneumatic concrete drilling truly dust-free?

A2: Pneumatic drilling with integrated dust collection systems significantly reduces* airborne dust, making it much cleaner than traditional methods. However, it’s rarely completely dust-free, and wearing a dust mask is still recommended for safety.

Q3: What kind of drill bits do I need for concrete?

A3: You’ll need masonry drill bits, typically carbide-tipped, designed for drilling into concrete. If your pneumatic drill has an SDS chuck, you’ll require SDS-shank bits.

Q4: How much PSI do I need for concrete drilling?

A4: Most pneumatic tools, including concrete drills, operate effectively between 90 and 1