Do you need a water separator for an air compressor? Yes, absolutely, especially if you value the longevity and performance of your air tools and the compressor itself. Moisture in compressed air can cause rust, damage delicate tool components, and lead to costly repairs. A water separator is a simple, effective solution to protect your investment and ensure clean, dry air for all your projects.

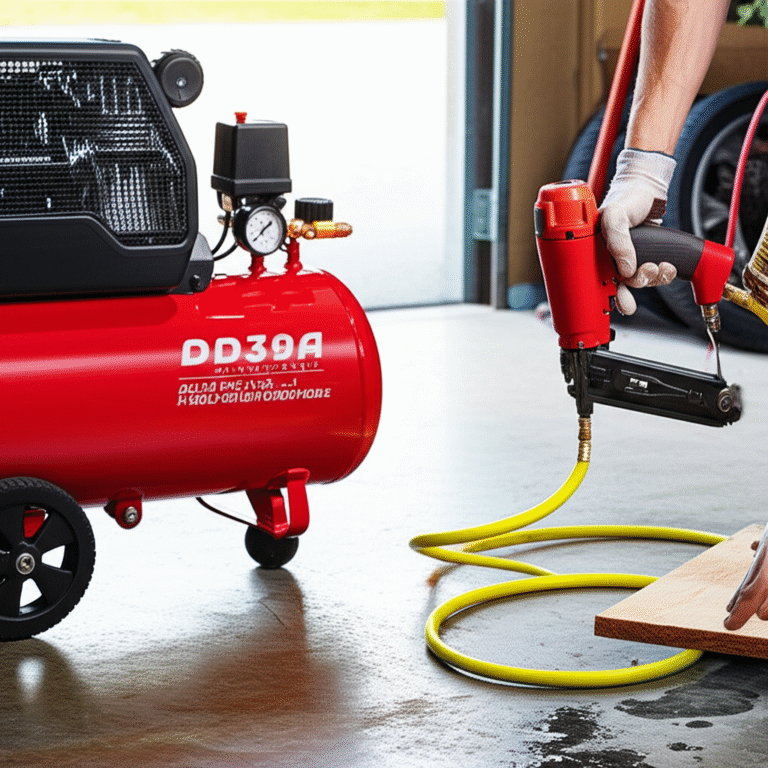

Ever notice a little bit of moisture when you use your air compressor? It’s a common thing, and frankly, it can be a bit frustrating. You’re all set to inflate tires, run that nail gun, or maybe even tackle a painting project, and then you see it – water. This isn’t just an annoyance; it can actually cause real problems for your tools and the compressor itself. But don’t worry, there’s a straightforward fix that many people overlook. We’re going to break down exactly why this happens and how a simple device, the water separator, can save you a lot of headaches and money. Stick around, and we’ll get your air compressor running as dry and efficiently as it should be.

Understanding Why Your Air Compressor Produces Moisture

Think about how an air compressor works. It takes in the surrounding air, compresses it, and stores it in a tank. The air around us, even on a dry day, contains moisture in the form of water vapor. When the compressor compresses this air, it also compresses the water vapor. As the compressed air cools down, this water vapor turns back into liquid water. This is similar to how condensation forms on the outside of a cold glass on a warm day.

This liquid water then collects in the air tank and can travel through your air lines to your tools. It’s a natural process, but it’s one you definitely want to manage. Without proper drainage or separation, this water can become a real problem.

The Problem with Water in Compressed Air

So, why is this water such a big deal? Well, it can lead to a few significant issues:

- Rust and Corrosion: Metal tanks and air tools are susceptible to rust when exposed to water. This can weaken the tank over time and damage the internal parts of your tools.

- Tool Damage: Delicate components within air tools, like pistons, valves, and seals, can be corroded or damaged by water. This can lead to reduced performance, leaks, and eventual tool failure.

- Poor Performance: Water can affect the lubrication of air tools, leading to sticky valves or reduced power. For tasks like painting, water droplets can ruin the finish.

- Freezing in Cold Weather: If water is left in the lines or tools during freezing temperatures, it can expand and cause significant damage, cracking components.

For homeowners and DIYers using compressors for tasks like inflating tires, running nail guns, or winterizing irrigation systems, these issues can mean unexpected repair bills or the premature demise of expensive tools. Protecting your equipment is key to saving money and getting the job done right.

What is a Water Separator?

A water separator, also known as an air filter or air dryer, is a device that attaches to your air compressor or air lines to remove moisture from the compressed air. They work in a few different ways, but the main goal is the same: to trap and drain away the water before it can reach your tools.

Think of it as a crucial gatekeeper for your compressed air. It intercepts the air, removes the unwanted water, and lets only clean, dry air pass through. This simple addition can make a world of difference in the efficiency and lifespan of your air compressor system.

Types of Water Separators

There are a few common types of water separators you’ll encounter, each with its own way of tackling moisture:

| Type | How it Works | Best For |

|---|---|---|

| In-line Desiccant Dryers | These use a material called desiccant (often silica gel) that absorbs moisture from the air. As the air passes through, the desiccant beads change color to indicate saturation, and they can often be regenerated by heating or simply replaced. | Fine detail work, painting, applications where extremely dry air is critical. |

| Refrigerated Air Dryers | These cool the compressed air to a low temperature, causing the water vapor to condense into liquid water, which is then drained away. They are more complex and typically used in industrial settings but are highly effective. | Continuous, high-volume use; industrial applications. |

| Moisture Traps / Water Filters | These are the most common and affordable type for home and DIY use. They often use a combination of filtering elements and a bowl where water collects. Many have a manual or automatic drain valve to release the accumulated water. Some also include a small oil filter or coalescing filter to remove oil and other contaminants. | Home garages, automotive hobbyists, DIY projects, running nail guns, inflating tires. |

For most homeowners and DIYers, the moisture trap or water filter type is the most practical and cost-effective solution. They are easy to install and maintain, providing a significant improvement in air quality for your tools.

Do You Need a Water Separator? Key Factors to Consider

The question of whether you need a water separator really boils down to a few key factors related to how you use your air compressor and the types of tools you connect to it.

1. Your Climate and Humidity Levels

If you live in a humid region, your air compressor will naturally draw in more moisture from the atmosphere. This means more water will condense in your tank and lines. In drier climates, you might see less water, but it’s still present. High humidity means a higher likelihood of problems if you don’t have a water separator.

2. The Type of Air Tools You Use

Some air tools are much more sensitive to moisture than others. For example:

- Pneumatic Nail Guns and Staplers: While generally robust, repeated exposure to water can cause internal rust and affect the smooth operation of the piston and seals.

- Air Sanders and Grinders: These tools have moving parts that rely on proper lubrication. Water can wash away lubricants and lead to premature wear.

- Paint Sprayers: This is where water can be a real disaster. Moisture in the air line can cause “fisheyes” or other imperfections in your paint finish, ruining hours of work.

- Impact Wrenches: Similar to sanders, the internal mechanisms can suffer from corrosion and lack of lubrication.

- Tire Inflators: While less sensitive, consistent moisture can still lead to corrosion in the pressure gauge or valve mechanism over time.

If you use any tools that have intricate moving parts, rely on precise operation, or are used for finishing work like painting, a water separator is highly recommended. For simple tasks like inflating tires, it’s less critical but still beneficial for long-term equipment health.

3. Frequency and Duration of Use

If you use your air compressor frequently or for extended periods, more air is compressed, and thus more water is generated. This increased volume of moisture makes a water separator even more important. For occasional, short bursts of use, the impact might be less immediate, but it’s still a good preventative measure.

4. The Material of Your Air Tank

Air compressor tanks are typically made of steel. Steel is prone to rust when exposed to moisture. While many tanks have internal coatings, these can degrade over time, especially if water is allowed to sit. A water separator helps protect the tank from internal corrosion.

5. Your Desire for Tool Longevity and Performance

Ultimately, if you want your air tools to last longer, perform at their best, and avoid costly repairs, you need to protect them from moisture. A water separator is a relatively inexpensive investment that pays for itself by extending the life of your tools and preventing performance issues.

How to Install a Water Separator

Installing a water separator is usually a straightforward process, especially for the common moisture trap types. They are designed to be user-friendly, even for beginners.

What You’ll Need:

- Your chosen water separator unit

- Pipe thread sealant (PTFE tape or pipe dope)

- Adjustable wrench or pliers

- Teflon tape (if your unit doesn’t have pre-applied sealant)

Installation Steps:

- Turn Off and Depressurize: Ensure your air compressor is turned off and the air tank is completely depressurized. Open the drain valve on the tank to release any stored air.

- Locate the Outlet: Identify the air outlet port on your air compressor tank or on your main air line. This is where the compressed air exits the compressor.

- Prepare the Threads: Clean the threads on the compressor outlet and the inlet of the water separator. Apply pipe thread sealant (PTFE tape or pipe dope) to the threads of the compressor outlet. Wrap the tape clockwise around the threads 2-3 times.

- Install the Separator: Carefully screw the water separator onto the compressor outlet. Hand-tighten it first to ensure it’s threading correctly.

- Tighten with a Wrench: Use an adjustable wrench or pliers to tighten the water separator. Be firm but avoid overtightening, which can damage the threads or the unit. Aim for snug, with no visible gaps. You want a good seal to prevent air leaks.

- Check for Leaks: Once installed, turn on your air compressor and let it build pressure. Listen for any hissing sounds that might indicate an air leak. If you detect a leak, turn off the compressor, depressurize the tank, and slightly tighten the fitting or reapply thread sealant if necessary.

Many water separators are designed to be installed directly onto the compressor’s tank outlet. Others might be installed further down the air line, perhaps before a manifold or at the point where you connect your air hose. For maximum benefit, consider installing one at the compressor outlet and potentially another one at the end of your main air line before it splits to different tools.

Maintaining Your Water Separator

A water separator is only effective if it’s properly maintained. The good news is that maintenance is usually quite simple:

- Regular Draining: This is the most crucial step. You need to periodically drain the water that collects in the separator’s bowl. Most have a small valve at the bottom. For manual drain types, open this valve briefly to let the water and any accumulated sediment out. For automatic drain types, they should do this for you, but it’s still a good idea to check them occasionally.

- Frequency of Draining: How often you need to drain depends on your usage and humidity. After each significant use is a good habit. If you use the compressor daily, you might need to drain it daily or even more often.

- Filter Element Replacement: If your water separator has a replaceable filter element (common in more advanced models or those that also filter oil), you’ll need to replace it according to the manufacturer’s recommendations. This is usually based on hours of use or when performance seems to degrade.

- Cleaning the Bowl: Occasionally, you might want to unscrew the collection bowl (after depressurizing the system!) and clean out any sediment or buildup.

Neglecting to drain your water separator will render it useless, as the bowl will fill up, and water will then bypass the filter and continue into your air lines. It’s a small task that makes a big difference.

When Might You NOT Need a Water Separator? (Rare Cases)

While I strongly advocate for using water separators, there are a few very niche scenarios where their necessity might be debated, though I’d still lean towards using one for best practice:

- Extremely Low-Use, Non-Critical Applications: If you only ever use your compressor to inflate bicycle tires a few times a year, and you don’t have any sensitive tools, the risk might be considered very low. However, even then, protecting the compressor itself is wise.

- Compressors with Built-in Advanced Drying Systems: Some high-end industrial compressors have integrated refrigerated or desiccant drying systems that are extremely efficient. In these cases, an additional separator might be redundant, but it’s important to understand the capabilities of your specific unit.

- Non-Metallic Tools or Systems: If you are using your compressed air solely for systems that are entirely non-metallic and not sensitive to moisture (which is rare in the DIY and homeowner space), the immediate risk of corrosion is eliminated.

Even in these cases, the benefits of cleaner air for the compressor’s internal mechanisms and smoother operation often outweigh the minor cost and effort of installing a separator. For the vast majority of users, especially those with pneumatic tools, a water separator is an essential component.

Cost vs. Benefit: Is it Worth It?

Let’s talk about value. A good quality moisture trap water separator for home or DIY use typically costs between $20 and $70. Compare this to the cost of a single air tool, which can range from $50 to several hundred dollars, or the cost of repairing a damaged compressor or tool. The math is pretty clear.

Consider these points:

- Tool Longevity: Extending the life of your air tools by even a year or two can easily justify the cost.

- Performance: Ensuring your tools work as they should, especially for tasks like painting or precision work, saves you from redoing jobs or buying new tools prematurely.

- Preventative Maintenance: It’s far cheaper to invest in a water separator than to deal with the fallout of water damage, which can include replacing corroded parts, fixing leaks, or even buying a new tool.

- Efficiency: Dry air generally leads to more consistent and efficient tool operation.

The benefit of clean, dry air far outweighs the small investment required for a water separator. It’s a smart purchase for anyone who relies on their air compressor.

Frequently Asked Questions (FAQ)

Q1: Do I need a water separator if I only use my air compressor for inflating tires?

While inflating tires is a less sensitive application, moisture can still cause corrosion in tire inflator gauges and valves over time. For the minimal cost and effort, adding a water separator is a good preventative measure to ensure your tire inflator lasts longer and functions accurately.

Q2: Can I just drain the tank every time instead of using a water separator?

Draining your air tank regularly is essential and a good practice, but it doesn’t remove moisture from the air as it passes through to your tools. Water separators filter the air before it reaches your tools, providing an extra layer of protection that simply draining the tank doesn’t offer.

Q3: How often should I drain my water separator?

You should drain your water separator after each significant use. If you live in a humid climate or use your compressor frequently, daily draining might be necessary. For automatic drain types, it’s still wise to check them periodically to ensure they are functioning correctly.

Q4: Will a water separator affect my compressor’s air pressure?

A properly functioning water separator should have a minimal impact on air pressure. Some very slight pressure drop can occur due to the filtration process, but it’s usually negligible and well within acceptable limits for most applications. If you notice a significant pressure drop, it might indicate a clogged filter or a faulty separator.

Q5: What’s the difference between a water separator and an air filter?

Often, these terms are used interchangeably, especially for the common moisture trap units. However, “air filter” can sometimes refer to a unit that primarily removes solid particles like dust and debris, while a “water separator” specifically targets liquid water. Many units combine both functions, removing water, oil, and particles.

Q6: Can I use a water separator with an air compressor that already has a tank drain?

Absolutely! In fact, you should. The tank drain removes water that has already collected in the tank. A water separator removes water from the air before it gets to your tools, offering a more immediate and continuous protection. They work together to keep your system dry