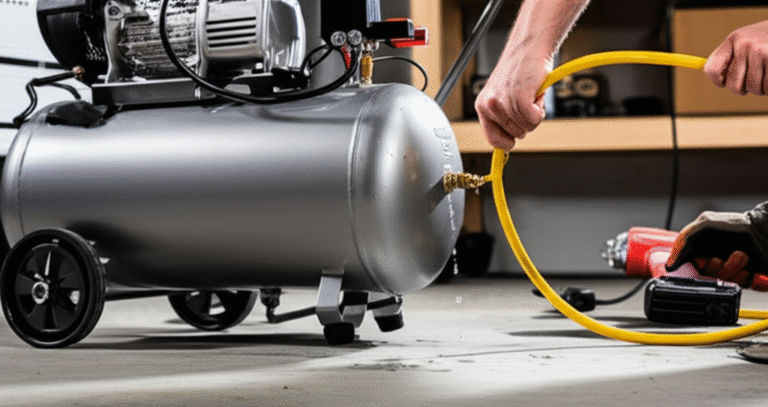

Quick Summary: Properly draining water from your air compressor is crucial for its longevity and performance. Regularly releasing this condensation prevents rust and damage to internal components. Follow these simple steps to ensure your compressor stays in top shape for all your DIY projects.

Got a bit of moisture in your air compressor? It’s a common thing, and honestly, it can be a bit of a headache if you don’t know what to do. That water can sneak in, cause rust, and really shorten the life of your valuable tools. But don’t worry! It’s not a complicated fix at all. Think of it like changing the oil in your car – a simple maintenance task that makes a huge difference. We’ll walk through exactly how to get that water out, step-by-step, so you can get back to inflating tires, powering your nail gun, or whatever your project needs. Let’s get this done right!

Why Draining Your Air Compressor Matters

Air compressors work by compressing air. As air is compressed, it heats up. When that hot, compressed air cools down, water vapor in the air condenses into liquid water. This is completely natural, just like dew forming on grass overnight. This collected water sits at the bottom of your air compressor tank. If left unchecked, this water can lead to some serious problems:

- Rust and Corrosion: Water is the enemy of metal. It will start to rust the inside of your air compressor tank, weakening it over time and potentially causing leaks.

- Tool Damage: If water gets into your air lines and then into your tools, it can damage sensitive components, leading to poor performance or complete failure. Think of your pneumatic tools like delicate machines – they don’t like water!

- Reduced Air Quality: Water in the air supply can affect the quality of your work, especially if you’re painting or using precision tools.

- Inefficiency: A tank compromised by rust might not hold pressure as efficiently, meaning your compressor has to work harder, using more energy.

Regularly draining the water is one of the simplest yet most effective ways to keep your air compressor running smoothly for years to come. It’s a small effort that pays big dividends in tool longevity and performance.

Understanding Your Air Compressor’s Drain Valve

Most air compressors have a drain valve located at the very bottom of the air tank. This is where all the collected water will exit. There are a few common types of drain valves:

Common Types of Drain Valves

| Valve Type | Appearance | How it Works | Ease of Use |

|---|---|---|---|

| Ball Valve | Looks like a small faucet handle. | Turn the handle 90 degrees to open, parallel to the pipe. | Very easy. |

| Gate Valve (or Globe Valve) | Has a wheel or knob that you turn. | Turn the wheel counter-clockwise to open. | Easy, but can sometimes be stiff. |

| Petcock Valve | A small spigot with a lever or wingnut. | Lift or turn the lever to open. | Easy, but can be small and fiddly. |

| Automatic Drain Valve | Often a small electrical or mechanical unit. | Opens automatically at set intervals or when pressure drops. | No manual effort required, but needs checking for proper function. |

No matter what type you have, the principle is the same: open it up, let the water out, and close it securely. We’ll cover how to do this safely in the next section.

Step-by-Step Guide: How to Properly Drain Water

Ready to tackle this essential maintenance? It’s straightforward. You’ll need a few minutes and maybe a rag or a small container, depending on your valve type and how much water you expect.

What You’ll Need:

- Your air compressor

- A rag or shop towel

- Optional: A small bucket or container (if your valve is tricky to control)

The Draining Process:

-

Turn Off and Depressurize: This is the most important safety step.

- Turn off your air compressor at the power switch.

- Unplug the compressor from the power source.

- Open the air outlet valve (where you connect your hose) to release any stored air pressure in the tank. Let all the air out until the gauge reads zero. This prevents a sudden forceful expulsion of water.

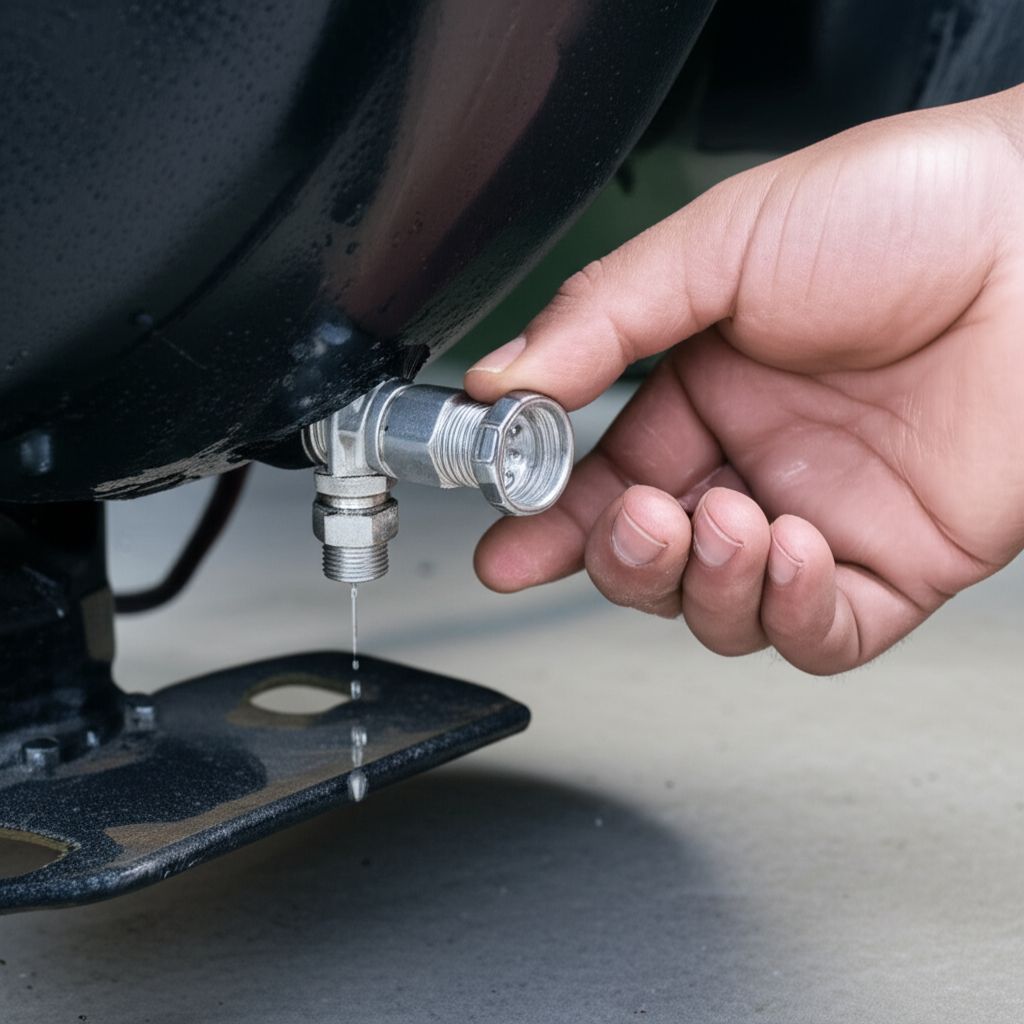

- Locate the Drain Valve: Get down low and look at the very bottom of the air tank. You should see one of the valve types we discussed earlier. It’s usually a brass or metal fitting with a handle or knob.

- Prepare for Drainage: Place your rag or a small bucket directly underneath the drain valve. This will catch any drips or splashes.

-

Open the Drain Valve:

- For Ball Valves: Gently turn the handle 90 degrees so it is perpendicular to the pipe it’s attached to.

- For Gate/Globe Valves: Turn the wheel or knob counter-clockwise. You don’t need to open it all the way, just enough to let the water out.

- For Petcock Valves: Lift the lever or turn the wingnut counter-clockwise.

You should hear a hissing sound as the water and any remaining air begins to drain out. You’ll likely see a stream of water, which may be cloudy or even contain some rust particles.

- Drain Until Only Air Escapes: Let the water drain until you only hear air hissing out, with no more liquid. This means the tank is empty of water.

-

Close the Drain Valve Securely: Once the water is gone, close the valve.

- For Ball Valves: Turn the handle back 90 degrees so it’s parallel to the pipe.

- For Gate/Globe Valves: Turn the wheel or knob clockwise until snug. Don’t overtighten.

- For Petcock Valves: Lower the lever or turn the wingnut clockwise until snug.

Ensure the valve is completely closed to prevent any leaks when you repressurize the tank.

- Final Check: Give the valve area a quick wipe with your rag to ensure it’s dry and that no water is dripping from it.

That’s it! You’ve successfully drained the water from your air compressor tank. It’s a simple process that protects your equipment.

How Often Should You Drain Your Air Compressor?

This is a great question, and the answer depends on a few factors, but here’s a good rule of thumb:

- After Every Use: This is the golden rule. Even if you only used the compressor for a short time, there’s a good chance some condensation formed. Draining it after each session is the best practice for preventing issues.

- At Least Weekly: If you don’t use your compressor very often, make it a habit to drain it at least once a week.

- In Humid Climates: If you live in a humid area, condensation can form more rapidly. You might need to drain it more frequently.

- Before Storage: If you’re storing your air compressor for an extended period (like over winter), drain it completely to prevent moisture from sitting in the tank.

Think of it this way: the more you use it, the more you should drain it. It’s better to drain it too often than not often enough.

Tips for Efficient Water Drainage

Here are a few extra tips to make draining your air compressor even easier and more effective:

- Use a Drain Hose Adapter: Some drain valves can be a bit awkward to get a container under. You can buy small adapters that screw onto the drain valve, allowing you to attach a short hose. This lets you direct the water into a bucket or onto a drain without bending down too much or making a mess.

- Consider an Automatic Drain: If you use your compressor frequently or find manual draining a hassle, you might consider upgrading to an automatic drain valve. These devices automatically expel water at set intervals or when the tank is empty, ensuring your tank stays dry without any effort from you. You can learn more about air compressor accessories and their benefits on resources like HomeTips.com.

- Check for Leaks After Draining: Once you’ve closed the drain valve, it’s a good idea to briefly pressurize the tank again and listen for any hissing sounds around the drain valve itself. If you hear any, the valve might not be fully closed or could be faulty and may need replacement.

- Don’t Forget the Hoses: While not part of draining the tank, it’s also a good practice to disconnect your air hose and let any moisture drain from it after use, especially if you’re in a cold climate and might be storing it where it could freeze.

Troubleshooting Common Drainage Issues

What if things don’t go quite as planned? Here are a few common issues and how to solve them:

Common Drainage Problems and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Valve is stuck or won’t open. | Corrosion, debris, or it hasn’t been used in a while. | Gently try wiggling the handle/knob. If it’s a ball valve, you might try tapping it lightly with a rubber mallet. If it’s very stubborn, you may need to apply a penetrating lubricant (like WD-40) and let it sit before trying again. Ensure the compressor is fully depressurized first. If it still won’t budge, it might need replacement. |

| Water won’t drain, only air. | Tank is already empty of water, or the valve is clogged. | If you’re sure there was water in it, the valve might be clogged. Try opening it fully and then closing it a few times. You might need to disconnect the valve (with the tank fully depressurized!) and clean it out. |

| Water still drips after closing the valve. | Valve is not fully closed, or the valve seat/washer is worn. | Ensure the handle is in the correct closed position. If it still drips, the valve might be damaged and require replacement. This is a common issue with older gate or petcock valves. |

| Valve is leaking air when closed. | The valve itself is faulty or the seal is worn. | This indicates the valve needs replacement. You can find replacement drain valves at most hardware stores or online tool suppliers. For guidance on air compressor maintenance and parts, resources like the Occupational Safety and Health Administration (OSHA) often have information on safe equipment operation, which indirectly relates to maintaining your tools. |

Most of these issues are minor and can be fixed with a little patience or a simple part replacement. The key is to address them promptly.

The Impact of Moisture on Air Quality

Beyond damaging your compressor and tools, moisture in your air supply can significantly impact the quality of your work. If you’re using your air compressor for painting, for example, water droplets in the air stream can cause:

- Fish Eyes: Small, crater-like defects in the paint finish.

- Blistering: Bubbles forming in the paint.

- Poor Adhesion: The paint not sticking properly to the surface.

Even for simpler tasks like inflating tires, consistently moist air can contribute to tire rot over long periods. While a small amount of water might not seem like a big deal, it adds up. Keeping your air dry is part of achieving professional results and ensuring the longevity of your projects and equipment.

Frequently Asked Questions (FAQs)

Is it okay to leave the drain valve slightly open?

No, it is not recommended to leave the drain valve slightly open. This will cause your compressor to constantly lose pressure, making it inefficient and unable to build up to its operating capacity. Always ensure the drain valve is securely closed when not in use.

Can I use my air compressor if there’s still some water in the tank?

While your compressor might still function, it’s not advisable. Even a small amount of water can be carried through the air lines and damage your tools or affect your work quality. It’s best to drain all the water before using the compressor.

What should I do with the drained water?

The drained water is typically just condensed moisture, sometimes with a bit of rust. You can usually dispose of it down a drain or outside, depending on local regulations. If you notice a significant amount of oil in the water, it might indicate a more serious internal issue with your compressor, and you should consult the manufacturer or a professional.

My compressor tank is very rusty inside. What can I do?

Significant rust inside the tank can be a sign that water was left in it for too long. While you can try to drain and dry the tank thoroughly, severe rust can compromise the tank’s integrity. For safety, it’s often recommended to replace a heavily rusted tank. Regular draining is the best preventative measure.

Do all air compressors produce water?

Yes, all air compressors that compress air will produce condensation. The amount of water produced depends on the humidity of the surrounding air, how much the compressor is used, and the ambient temperature. It’s a natural byproduct of the compression process.

Can I use a wrench to open the drain valve if it’s hard to turn?

It’s generally best to avoid using a wrench on standard drain valves unless they are specifically designed for it (like some older gate valves with a square stem). Using a wrench on ball valves or petcock valves can easily damage the handle or the valve itself, leading to leaks. Try gentle manual pressure first, or a penetrating lubricant if it’s stuck.

Conclusion

Taking a few minutes to properly drain the water from your air compressor after each use is one of the simplest, most effective ways to protect your investment. It prevents rust, keeps your tools running smoothly, and ensures you get the best performance from your compressor for all your home projects. Remember to turn off and depressurize the tank first, locate that drain valve, open it up until only air escapes, and then close it securely. You’ve got this! By making this a regular habit, you’ll be enjoying your air compressor for many years to come.