Wondering how an air compressor works? It’s simpler than you think! An air compressor takes in ambient air, compresses it into a smaller volume, and stores it under pressure in a tank. This pressurized air is then released on demand to power tools, inflate items, or perform various tasks, making it a versatile workshop essential.

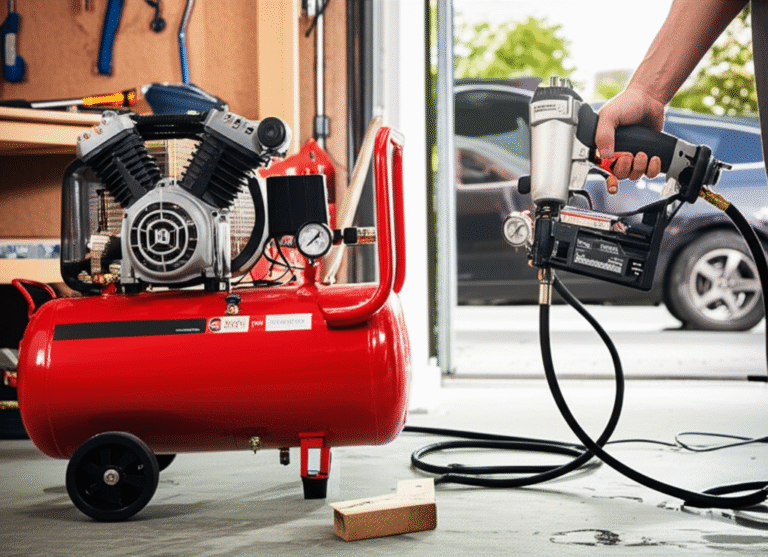

Welcome to Capische! If you’ve ever stared at an air compressor, wondering about the magic that turns a quiet motor into a powerful burst of air, you’re in the right place. Many of us have been there, feeling a bit overwhelmed by the sheer mechanics of it all. But honestly, understanding how an air compressor works is key to using it effectively and safely. It’s not about becoming an engineer; it’s about demystifying a fantastic tool that can save you time and money on countless home and automotive projects. We’ll break down the process step-by-step, so you can feel confident using your compressor for everything from inflating tires to running that nail gun you’ve been eyeing. Let’s dive in and uncover the genius behind this essential piece of equipment!

The Heart of the Machine: What is an Air Compressor?

At its core, an air compressor is a device that converts rotational energy, usually from an electric motor or gasoline engine, into potential energy stored in pressurized air. Think of it like a pump, but instead of pumping water, it’s pumping air. This pressurized air is then stored in a tank, ready to be released when you need it to power pneumatic tools, inflate tires, or even clean up dust around your workshop.

These machines are incredibly versatile and can be found in garages, workshops, construction sites, and even in portable versions for on-the-go tasks. The ability to harness the power of compressed air opens up a world of possibilities for DIYers and professionals alike.

How an Air Compressor Works: A Step-by-Step Breakdown

The process might seem complex, but it follows a logical sequence. Let’s break down the journey of air from the atmosphere into your compressor’s tank.

1. Air Intake

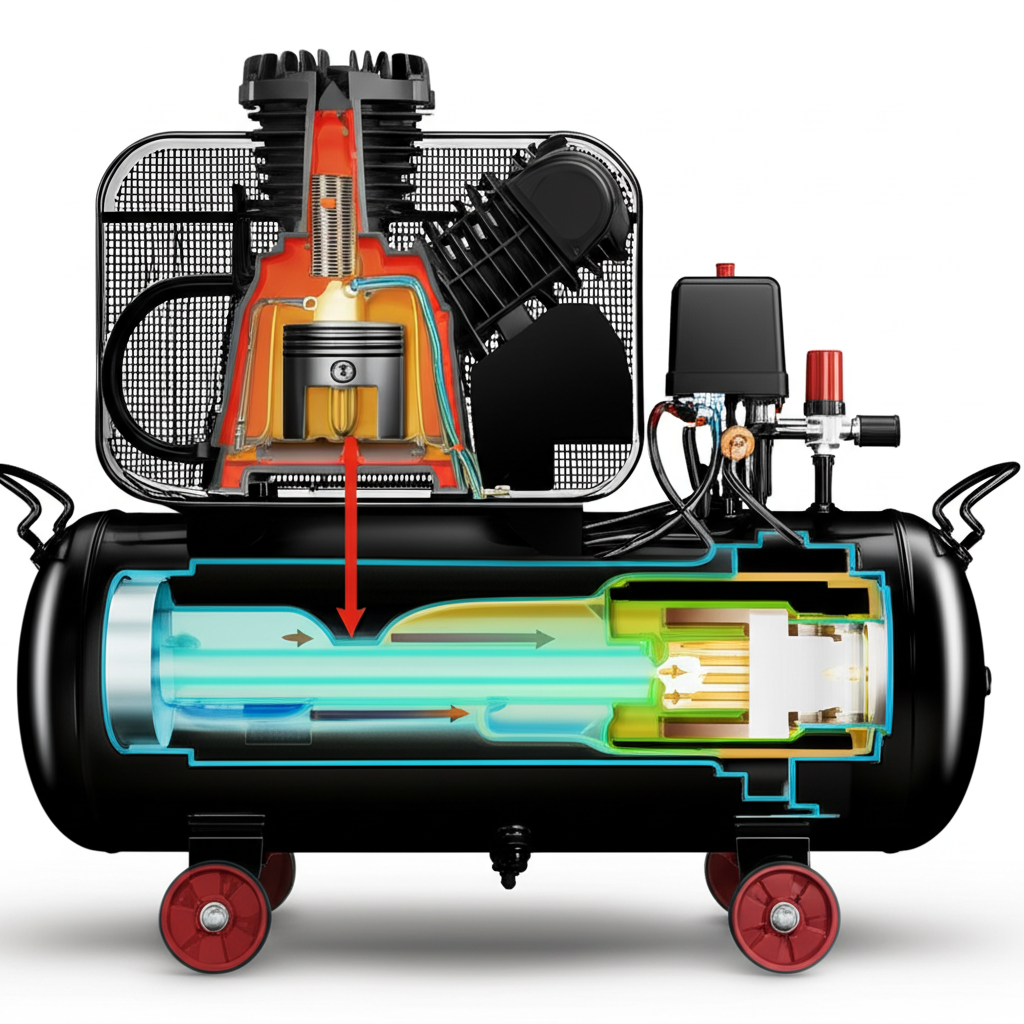

Everything starts with the air around us. The compressor’s motor drives a pump. This pump has an intake valve. When the piston inside the pump moves down, it creates a vacuum. This vacuum pulls in ambient air from the atmosphere through an air filter. The air filter is crucial; it removes dust, dirt, and other contaminants that could damage the compressor’s internal components or affect the quality of the air output. A clean filter ensures longer life and better performance for your compressor.

Think of the air filter like the lungs of the compressor. Just as our lungs need clean air to function, so does the compressor. Regularly checking and cleaning or replacing this filter is a simple maintenance step that makes a big difference.

2. Compression

Once the air enters the cylinder, the piston moves back up. This upward motion closes the intake valve and compresses the air into a smaller volume. As the air is squeezed, its pressure and temperature increase significantly. This is the core function of the compressor – increasing the air’s pressure.

The type of pump dictates how this compression happens:

- Piston Compressors: These are the most common for home and DIY use. They work much like the engine in your car, with pistons moving up and down within cylinders.

- Rotary Screw Compressors: Often found in industrial settings, these use two interlocking rotating screws to trap and compress air. They offer continuous airflow but are generally more expensive and complex.

- Centrifugal Compressors: These use a spinning impeller to force air outwards, increasing its velocity and then converting that velocity into pressure. They are typically used for very large-scale applications.

For most of us, we’ll be dealing with piston compressors, which can be either single-stage or two-stage.

Single-Stage vs. Two-Stage Compression

This is an important distinction:

| Feature | Single-Stage Compressor | Two-Stage Compressor |

|---|---|---|

| Compression Process | Air is compressed in one stroke of the piston. | Air is compressed in two stages. It’s compressed once, cooled, and then compressed again to a higher pressure. |

| Pressure Output | Lower to medium pressure (typically up to 135 PSI). | Higher pressure (often 175 PSI and above). |

| Duty Cycle | Generally designed for intermittent use. | Can handle continuous operation better due to less heat buildup. |

| Ideal Use Cases | Inflating tires, powering brad nailers, light stapling, blowing dust. | Running impact wrenches, sanders, paint sprayers, air-impact tools requiring higher CFM and PSI. |

| Cost | More affordable. | Typically more expensive. |

Choosing between single-stage and two-stage depends on the tools you plan to use. If you’re just topping off tires or using a small brad nailer, a single-stage compressor will likely suffice. For more demanding tasks like running an impact wrench or a paint sprayer, a two-stage compressor is a better investment.

3. Air Cooling

After the initial compression, the air is hot. Before it’s sent to the tank, it often passes through an intercooler (in two-stage compressors) or an aftercooler. These are essentially finned tubes that help dissipate the heat. Cooling the air before it enters the tank has several benefits:

- Increased Efficiency: Cooler air is denser, meaning more air molecules can fit into the tank for the same volume, leading to more usable air.

- Reduced Moisture: As hot, compressed air cools, water vapor within it condenses into liquid water. This is a critical step in moisture removal.

- Component Longevity: Lower operating temperatures reduce stress on the compressor’s components.

4. Air Storage (The Tank)

The compressed, cooled air is then directed into a storage tank. This tank acts as a reservoir, holding the pressurized air until it’s needed. The tank has a pressure gauge that shows how much air is stored and a pressure switch that automatically turns the motor on and off to maintain the desired pressure range.

When the pressure in the tank drops below a certain level (the cut-in pressure), the pressure switch activates the motor to start compressing more air. When the tank reaches its maximum set pressure (the cut-out pressure), the switch deactivates the motor. This cycle ensures you always have a supply of compressed air available.

5. Air Release and Regulation

When you connect a tool or an air hose, you open a valve. This allows the pressurized air from the tank to flow out. Most compressors have a regulator that allows you to adjust the output pressure to the specific requirements of your tool. Too much pressure can damage a tool, while too little can lead to poor performance.

It’s important to consult your tool’s manual for the recommended operating pressure. Using the correct pressure ensures optimal performance and prevents premature wear on your tools.

6. Moisture Drainage

As we mentioned, cooling compressed air causes moisture to condense. This water collects at the bottom of the storage tank. If not drained regularly, this water can cause the tank to rust from the inside out, potentially leading to tank failure – a serious safety hazard. Most tanks have a drain valve at the bottom. It’s essential to open this valve periodically to release the accumulated water.

For a more in-depth look at compressor maintenance, including moisture drainage, you can check out resources from the National Institute for Occupational Safety and Health (NIOSH), which provides valuable safety guidelines for compressed air systems.

Key Components of an Air Compressor

To fully grasp how an air compressor works, it’s helpful to know its main parts:

- Motor: The power source, usually electric or gasoline, that drives the pump.

- Pump/Compressor Unit: The mechanism that draws in and compresses air. This is often a piston-driven assembly.

- Air Intake Filter: Cleans the air before it enters the pump.

- Cylinders and Pistons: The heart of a piston compressor, where air is physically squeezed.

- Valves (Intake and Discharge): Control the flow of air into and out of the cylinders.

- Intercooler/Aftercooler: Cools the air between compression stages or before it enters the tank.

- Storage Tank: Holds the compressed air.

- Pressure Switch: Automatically turns the motor on and off to maintain tank pressure.

- Pressure Gauge: Displays the air pressure in the tank.

- Regulator: Adjusts the output air pressure to the desired level.

- Safety Relief Valve: A crucial safety device that releases excess pressure if the pressure switch fails.

- Drain Valve: Located at the bottom of the tank to release accumulated water.

Types of Air Compressors and Their Working Principles

While the basic principle of compressing air remains the same, different types of compressors are designed for different needs. The most common types you’ll encounter are:

1. Piston Air Compressors

These are the workhorses for most home garages and DIY applications. They use a reciprocating piston inside a cylinder to compress air. As the piston moves down, it draws air in through an intake valve. As it moves up, it compresses the air and pushes it out through a discharge valve.

Sub-types include:

- Single-Stage: Compresses air in one stroke. Good for light-duty tasks.

- Two-Stage: Compresses air in two steps, with cooling in between. Suitable for heavier-duty applications requiring higher pressure and continuous use.

2. Rotary Screw Air Compressors

These are more common in industrial settings. They use two meshing helical screws that rotate in opposite directions. As the screws turn, air is trapped in the pockets between the screws and the casing. The rotation of the screws forces the air into progressively smaller volumes, thus compressing it. They provide a continuous, oil-free (in some models) supply of air and are designed for heavy, continuous operation.

3. Diaphragm Air Compressors

These compressors use a flexible diaphragm that moves up and down. The diaphragm is connected to a motor via a crankshaft. When the diaphragm moves down, it creates a vacuum, drawing air in through an intake valve. When it moves up, it pushes the air out through a discharge valve. These are often used for low-pressure, low-volume applications and are typically oil-free.

4. Scroll Air Compressors

Scroll compressors use two spiral-shaped scrolls. One scroll is fixed, while the other orbits around it. As the orbiting scroll moves, it traps pockets of air between the two scrolls. The orbiting motion causes these pockets to move towards the center, where the air is compressed. They are known for their quiet operation and oil-free air output, making them suitable for applications where air quality is paramount.

Understanding Key Air Compressor Metrics: PSI, CFM, and HP

When choosing an air compressor, you’ll encounter several important metrics. Knowing what they mean is crucial for matching the compressor to your needs.

- PSI (Pounds per Square Inch): This measures the air pressure. Most tools have a specific PSI requirement for optimal operation. Higher PSI means more force.

- CFM (Cubic Feet per Minute): This measures the volume of air the compressor can deliver. It’s often more critical than PSI for determining if a compressor can run a tool. Tools that use a lot of air (like sanders or paint sprayers) require a higher CFM rating. You’ll often see CFM ratings at different PSI levels (e.g., 5 CFM at 90 PSI).

- HP (Horsepower): This indicates the power of the motor driving the compressor. While important, CFM is often a better indicator of a compressor’s capability, as motor efficiency can vary.

A good rule of thumb is to choose a compressor that can deliver at least 1.5 times the CFM required by your most demanding tool at the tool’s operating PSI. For example, if your impact wrench requires 5 CFM at 90 PSI, look for a compressor that can deliver at least 7.5 CFM at 90 PSI.

Safety First: Essential Precautions

Working with compressed air can be dangerous if proper safety measures are not followed. Here are some vital precautions:

- Always wear safety glasses: Protect your eyes from flying debris or sudden air bursts.

- Inspect the tank regularly: Check for rust, corrosion, or damage. Never use a tank that appears compromised.

- Drain the tank daily: Prevent moisture buildup and potential tank failure.

- Understand the safety relief valve: Ensure it’s functioning correctly and never tamper with it.

- Use the correct pressure regulator: Set the pressure according to your tool’s requirements.

- Never point an air hose at yourself or others: Even low-pressure air can cause injury.

- Ensure proper ventilation: Especially if using a gas-powered compressor indoors.

- Read the owner’s manual: Familiarize yourself with your specific compressor’s operating and safety instructions.

For comprehensive safety guidelines, the NIOSH document on compressed air safety is an excellent resource.

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of an air compressor?

The main purpose of an air compressor is to take in ambient air, compress it into a smaller volume, and store it under pressure in a tank. This pressurized air is then used to power various tools and equipment.

Q2: How does a piston air compressor work?

A piston air compressor uses a piston moving up and down inside a cylinder. As the piston moves down, it draws air in through an intake valve. As it moves up, it compresses the air and forces it out through a discharge valve into the storage tank.

Q3: Why is it important to drain the air compressor tank?

It’s crucial to drain the tank to remove accumulated water. This condensation happens as the compressed air cools. If not removed, the water can cause the tank to rust from the inside, leading to potential structural weakening and safety hazards.

Q4: What’s the difference between single-stage and two-stage compressors?

A single-stage compressor compresses air once, suitable for lighter tasks. A two-stage compressor compresses air twice, with cooling in between, achieving higher pressures and better efficiency for more demanding applications.

Q5: What do PSI and CFM mean for an air compressor?

PSI (Pounds per Square Inch) measures air pressure, while CFM (Cubic Feet per Minute) measures the volume of air delivered. Both are critical for ensuring your tools receive the correct amount of air at the right pressure to function properly.

Q6: How often should I check the air filter?

It’s recommended to check the air filter regularly, perhaps every few uses or at least monthly, depending on how dusty your environment is. Clean or replace it as needed to ensure efficient operation and prevent damage to the compressor.

Conclusion

Understanding how an air compressor works demystifies a powerful tool that can significantly enhance your DIY capabilities. From the simple intake of air to its forceful release, each step plays a vital role in delivering the compressed air you need. By knowing the basic mechanics, the function of key components like the pump, tank, and regulator, and the importance of metrics like PSI and CFM, you’re well-equipped to select, use, and maintain your air compressor effectively. Remember to always prioritize safety, perform