Should the drain valve be closed on an air compressor? Yes, the drain valve on your air compressor must be closed during operation to build and maintain air pressure. Leaving it open will prevent the compressor from pressurizing and can lead to damage. This guide explains why and when to open it.

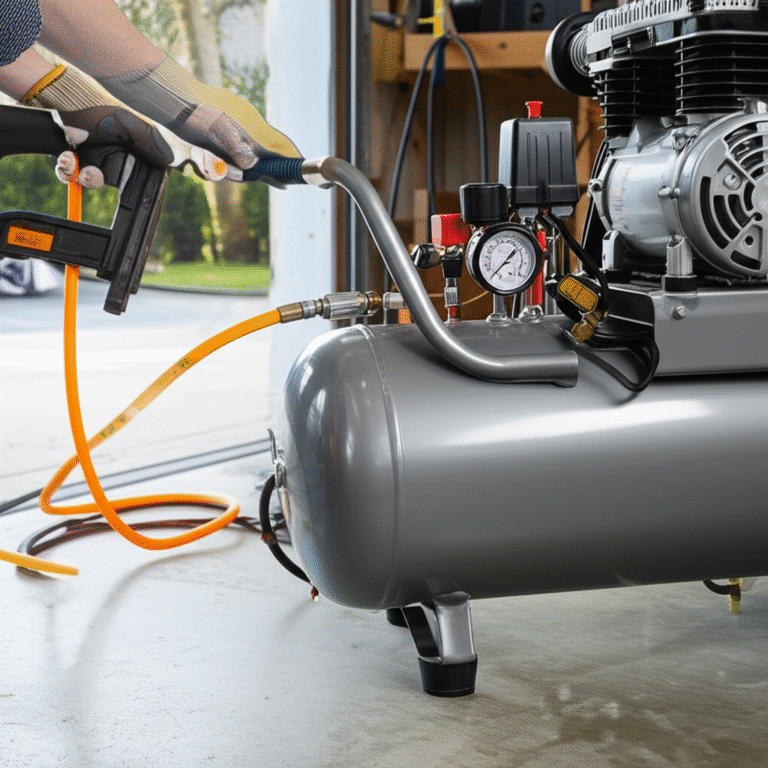

Got an air compressor and wondering about that little valve at the bottom? It’s a common question, especially when you’re just starting out. You might look at it and think, “What’s this for? And should it be open or closed when I’m using my compressor?” It can feel a bit confusing, but don’t worry! Understanding this simple valve is key to keeping your compressor running smoothly and efficiently. We’ll walk through exactly what you need to know, step by step, so you can use your air compressor with confidence.

Understanding Your Air Compressor’s Drain Valve

Let’s talk about that valve at the very bottom of your air compressor’s tank. It’s often called a drain valve, petcock, or sometimes a boiler drain. Its primary job is crucial for the health and longevity of your air compressor. Think of it as a tiny but mighty gatekeeper for moisture.

Why Does Moisture Matter?

Air, when compressed, heats up. As this hot air cools inside the tank, water vapor condenses into liquid water. This is completely normal, just like condensation on a cold glass of water. However, water and metal don’t mix well over time.

Rust: Water trapped in the steel tank will cause it to rust from the inside out. This can weaken the tank, create leaks, and eventually lead to catastrophic failure, which is incredibly dangerous.

Contamination: Water in the tank can also get into your air lines and tools. This can damage sensitive pneumatic tools, cause paint to spray unevenly, or even ruin projects.

The drain valve is your tool to get rid of this collected moisture.

The Golden Rule: Keep It Closed During Operation

So, to answer the main question directly: Yes, the drain valve should always be closed when you are operating your air compressor and need it to build pressure.

Why? Imagine trying to fill a bucket with a hole in the bottom. That’s essentially what you’d be doing if you left the drain valve open while the compressor is running.

Pressure Loss: The compressor pumps air into the tank, but as soon as it’s generated, it escapes through the open drain valve. The tank will never reach its intended operating pressure.

Inefficiency: Your compressor will run constantly, trying to build pressure that it can’t hold. This wastes electricity and puts unnecessary wear and tear on the motor and pump.

No Air Supply: You won’t have any usable compressed air for your tools or tasks.

This is why ensuring the drain valve is tightly shut is the first step before you even turn on your compressor.

When and How to Open the Drain Valve

The drain valve is only opened to release the accumulated moisture and, sometimes, to drain the tank completely.

When to Drain

It’s best practice to drain your air compressor tank regularly. How often depends on how much you use it and the humidity in your environment.

After Each Use: This is the ideal scenario. It’s a simple habit that significantly extends the life of your compressor.

Weekly: If you use your compressor frequently but not for extended periods, a weekly drain might suffice.

Monthly: For very light users, a monthly drain could be acceptable, but checking for moisture buildup more often is always better.

A good rule of thumb is to check for water accumulation in the tank. If you see even a small amount, it’s time to drain.

How to Drain Your Air Compressor Tank

Draining is a straightforward process. Here’s how to do it safely:

1. Turn Off the Compressor: Always start by switching off the power supply to the compressor. Unplug it if possible for added safety.

2. Release Air Pressure: If there’s still pressure in the tank, you’ll need to release it before opening the drain valve. You can do this by:

Using a Tool: Connect an air hose to the outlet and briefly open the chuck to let the air out.

Opening the Regulator: Some compressors have a regulator that can be pulled or pushed to release tank pressure.

Wait: If no tools are connected and you don’t have a release mechanism, you can simply wait for the pressure to bleed off naturally if you had left the outlet valve slightly open. However, it’s best to actively release pressure.

3. Position a Container: Place a suitable container, like a drip pan or an old bucket, directly under the drain valve. This will catch the water and any residual air.

4. Open the Drain Valve:

Ball Valve Type: These usually have a lever handle. Turn the lever so it’s perpendicular (90 degrees) to the valve body. This opens the valve.

Petcock Type: These often have a small knob or wingnut. Turn the knob or wingnut to open the valve.

Quick-Release Type: Some newer models have a quick-release button or lever.

5. Let It Drain: Allow all the water to drain out. You might hear a hiss of air escaping. If there’s a lot of water, it might take a minute or two.

6. Close the Drain Valve: Once the water has stopped draining and only air (or nothing) is coming out, close the drain valve firmly. For ball valves, turn the lever parallel to the valve body. For petcocks, tighten the knob or wingnut. Ensure it’s snug, but don’t overtighten.

7. Check for Leaks: After closing, turn the compressor back on and let it build pressure. Listen carefully around the drain valve for any hissing sounds, which would indicate it wasn’t closed tightly enough.

Here’s a quick reference table for common drain valve types:

| Valve Type | How to Open | How to Close |

| :—————- | :———————- | :———————- |

| Ball Valve | Turn lever 90° | Turn lever 0° (parallel) |

| Petcock (Knob) | Turn knob clockwise | Turn knob counter-clockwise |

| Petcock (Wingnut) | Tighten wingnut slightly | Loosen wingnut slightly |

| Quick-Release | Push button/lever | Release button/lever |

Note: Always refer to your specific air compressor’s manual for the most accurate instructions.

Troubleshooting Common Drain Valve Issues

Sometimes, things don’t go as smoothly as planned. Here are a few common problems you might encounter with your drain valve:

1. The Valve Won’t Open or Close Properly

This is often due to corrosion or sediment buildup.

What to Do:

Ensure all tank pressure is released first.

Try applying a penetrating lubricant (like WD-40, but use sparingly and wipe away excess) to the valve threads. Let it sit for a few minutes.

Gently tap the valve handle or knob with a rubber mallet or the handle of a screwdriver to try and break the corrosion free.

If it’s a ball valve, try wiggling the handle back and forth gently.

If it still won’t budge, it might need replacement.

2. The Valve Leaks After Closing

This usually means the seal isn’t tight or the valve seat is damaged.

What to Do:

Make sure you closed it firmly. For ball valves, ensure the lever is fully parallel to the valve body.

If it’s a petcock type, try tightening the packing nut (if it has one) slightly.

Check the valve seat for any debris. You might be able to clean it by slightly opening and closing the valve while a rag is held near it.

If the leak persists, the valve may need to be replaced. Many replacement valves are readily available at hardware stores or online. You can find common types, like a 1/4-inch NPT ball valve, which is a standard size for many compressors.

3. Water Doesn’t Drain Out Completely

This can happen if the tank isn’t tilted correctly or if there’s a blockage.

What to Do:

Ensure the compressor tank is level or slightly tilted towards the drain valve.

If you suspect a blockage, try opening the valve fully and then closing it quickly a few times to dislodge any debris.

If it’s a ball valve, ensure the ball inside isn’t damaged or stuck.

The Importance of Regular Maintenance

Taking a few minutes after each use to drain your air compressor is a small effort that pays big dividends. It’s a fundamental part of air compressor maintenance that prevents costly repairs down the line.

Think about it: a new air compressor can be a significant investment. Protecting that investment with simple, regular maintenance is just smart. For more in-depth maintenance tips, resources like the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) often provide guidelines on maintaining industrial equipment, which can be adapted for understanding best practices for air compressors. While their focus is industrial, the principles of moisture management and equipment care are universal.

When to Use Compressed Air and How Pressure Affects It

Understanding your drain valve is part of a larger picture of using your air compressor effectively. Whether you’re inflating tires, powering a nail gun, or prepping a surface for painting, the quality of the air coming from your compressor matters.

Tire Inflation: Clean, dry air ensures your tires inflate correctly and helps prevent premature wear.

Nail Guns & Tools: Moisture can cause internal rust and gum up the delicate mechanisms inside pneumatic tools, leading to poor performance or complete failure.

Paint Sprayers: Water droplets in the air supply can cause “fisheyes” or an uneven finish on painted surfaces.

The pressure setting on your regulator is also crucial. Always consult the tool’s manual for the recommended operating pressure. Too much pressure can damage the tool, and too little won’t allow it to function correctly.

Frequently Asked Questions (FAQ)

Frequently Asked Questions About Air Compressor Drain Valves

Q1: Do I need to drain my air compressor every time I use it?

Yes, it is highly recommended to drain your air compressor tank after each use. This practice removes accumulated moisture, preventing rust and corrosion inside the tank and ensuring cleaner air for your tools.

Q2: What happens if I leave the drain valve open while the compressor is running?

If you leave the drain valve open, the compressor will not be able to build or maintain air pressure in the tank. The air being pumped in will escape through the open valve, leading to inefficient operation, wasted energy, and no usable compressed air.

Q3: How can I tell if my air compressor tank has water in it?

You can check for water by carefully opening the drain valve after the compressor has cooled down and all pressure has been released. If water comes out before air, or if you see moisture dripping from the valve, there is water in the tank.

Q4: My drain valve is stuck. What should I do?

If your drain valve is stuck, ensure all tank pressure is released. Try applying a penetrating lubricant to the valve stem or threads and let it sit. Gently tapping the handle with a rubber mallet might also help free it. If it remains stuck, it may need to be replaced.

Q5: Can water in the tank damage my air tools?

Absolutely. Water in the tank can travel through the air lines and into your tools. This moisture can cause internal rust, corrosion, and gumming of moving parts, leading to reduced tool performance, leaks, and premature failure.

Q6: What kind of container should I use to catch the drained water?

A simple drip pan, a sturdy bucket, or any container capable of holding liquid and catching potential splashes is suitable. Ensure it’s stable and won’t tip over.

Q7: Is it safe to replace the drain valve myself?

Yes, replacing a drain valve is a common DIY maintenance task. Ensure the compressor is unplugged, completely depressurized, and you have the correct replacement valve (usually with NPT threads) and thread sealant tape. If you’re unsure, consult your compressor’s manual or a qualified technician.

Conclusion

So there you have it! The mystery of the drain valve is solved. Keeping that little valve closed during operation is non-negotiable for building pressure and using your air compressor effectively. But remember, opening it to drain out that pesky moisture after each use is just as important for the long-term health of your equipment.

By following these simple steps – close it to run, open it to drain – you’re not just maintaining your air compressor; you’re ensuring it performs reliably, safely, and efficiently for years to come. Happy compressing!