Choosing the right hacksaw blade for metal is simple: for most common metal cutting, a 24 TPI (Teeth Per Inch) blade is your best bet. For harder metals, opt for a 32 TPI blade. Always ensure the blade has the correct tension and is properly seated in your hacksaw frame for clean, safe cuts.

Hey there, DIYer! Ever stared at a pile of metal, ready to tackle a project, only to get confused by all the different hacksaw blades? You’re not alone! Picking the right blade can feel like a puzzle, but it doesn’t have to be. Using the wrong blade can lead to frustratingly slow cuts, broken teeth, or even a bent blade. But don’t worry, with a little know-how, you’ll be cutting metal like a pro in no time. We’re going to break down exactly what you need to know to choose the perfect hacksaw blade for your metal-cutting needs, making your projects smoother and more successful. Let’s get those cuts clean and easy!

Understanding Hacksaw Blades: The Basics

A hacksaw is a fantastic tool for cutting various materials, but its real magic lies in the blade. Hacksaw blades are thin, flexible strips of metal with sharp teeth designed to remove material as they move. They come in different lengths, but the most crucial differences for cutting metal are the material they’re made from and, most importantly, the number of teeth per inch (TPI).

Think of TPI as the “grit” of your saw blade. More teeth mean finer cuts, while fewer teeth mean faster, more aggressive cuts.

The Key to a Good Cut: Teeth Per Inch (TPI)

The number of teeth per inch (TPI) on a hacksaw blade is the single most important factor when choosing a blade for metal. It dictates how the blade interacts with the material you’re cutting.

- Low TPI (e.g., 14-18 TPI): These blades have fewer, larger teeth. They are designed for cutting thicker, softer metals like aluminum or mild steel. The larger teeth can bite into the material more aggressively, removing material quickly. However, they can snag on thinner materials, leading to rough cuts or broken teeth.

- Medium TPI (e.g., 20-24 TPI): This is your all-around workhorse for metal. Blades with 20 to 24 TPI are excellent for cutting a wide range of common metals, including medium-thickness steel, copper, and brass. They offer a good balance between cutting speed and cut quality.

- High TPI (e.g., 32 TPI): These blades have many small, fine teeth. They are ideal for cutting thin, hard metals like stainless steel, conduit, or thin-walled tubing. The fine teeth ensure that at least two or three teeth are always in contact with the metal, preventing snagging and providing a smooth, clean cut.

Here’s a quick reference table to help you match TPI to metal thickness:

| Material Thickness | Recommended TPI | Blade Type Example |

|---|---|---|

| Thin Metal (e.g., sheet metal, thin tubing, conduit) | 32 TPI | Fine-tooth, High TPI |

| Medium Metal (e.g., bolts, rods, pipes, angle iron) | 24 TPI | All-purpose, Medium TPI |

| Thick Metal (e.g., thick bars, heavy pipe) | 18 TPI | Coarse-tooth, Low TPI |

Blade Material: Durability and Performance

Hacksaw blades are typically made from one of three materials, each offering different levels of durability and cutting performance:

- Carbon Steel: These are the most basic and least expensive blades. They are suitable for cutting softer metals like plastic or wood. However, they dull quickly when used on harder metals and can easily break. They are not recommended for serious metal cutting.

- High-Speed Steel (HSS): HSS blades are a significant upgrade. They are hardened to withstand higher temperatures generated during metal cutting, meaning they stay sharp longer and are more durable than carbon steel blades. These are a good choice for general metalwork.

- Bi-Metal: These are the premium choice for most metal cutting. Bi-metal blades combine the flexibility of a spring steel back with the hardness of HSS teeth. This makes them incredibly durable, less prone to shattering, and able to cut through a wider range of metals, including harder alloys. They offer the best longevity and performance for demanding tasks. For serious metal cutting, investing in bi-metal blades is highly recommended.

Which Hacksaw Blade for Metal: The Proven Best

When it comes to cutting metal, especially for general DIY tasks, a few types of blades stand out as the most effective and versatile.

The All-Around Champion: 24 TPI Bi-Metal Blades

If you’re just starting or want a blade that can handle most common metal-cutting jobs, the 24 TPI bi-metal hacksaw blade is your go-to. Here’s why:

- Versatility: It’s perfect for cutting medium-thickness metals like steel rods, pipes, bolts, and angle iron. This covers a vast majority of home repair and DIY projects.

- Durability: Being bi-metal, these blades are tough. They can handle the heat and friction of cutting metal without easily breaking or dulling, unlike cheaper carbon steel blades.

- Good Cut Quality: The 24 TPI offers a nice balance, providing a reasonably fast cut without sacrificing too much on smoothness. You’ll get clean enough results for most applications.

For example, if you need to cut a standard steel bolt to size or trim a piece of copper pipe, a 24 TPI bi-metal blade will get the job done efficiently and cleanly.

For Thinner, Harder Metals: 32 TPI Bi-Metal Blades

When you encounter thinner or harder metals, you’ll want to switch to a blade with more teeth.

- Precision for Thin Materials: A 32 TPI bi-metal blade is designed for cutting materials like thin-walled tubing, conduit, or stainless steel. The finer teeth ensure that multiple teeth are always engaged with the metal. This prevents the blade from skipping or snagging, which can happen with coarser blades on thin stock.

- Smooth Finishes: These blades produce a much smoother cut, which is often desirable when working with decorative metals or when the cut surface will be visible.

- Durability: Again, bi-metal construction ensures these fine-tooth blades are still robust enough to handle the job without frequent breakage.

A good example is cutting electrical conduit for a home wiring project or trimming a thin stainless steel rod for a craft project. A 32 TPI blade will give you the control and clean finish needed.

When to Use Lower TPI Blades (Less Common for General Metal)

While 24 TPI and 32 TPI cover most needs, you might see blades with lower TPI (18 TPI or even 14 TPI). These are generally reserved for cutting thicker, softer metals like:

- Thick aluminum extrusions

- Thick copper or brass bars

- Very thick steel stock

For most beginners and DIYers, these lower TPI blades are less frequently needed. Focusing on 24 TPI and 32 TPI bi-metal blades will serve you well.

How to Choose and Use Your Hacksaw Blade

Now that you know about TPI and blade materials, let’s walk through selecting and using your blade correctly.

Step-by-Step Blade Selection Guide

- Identify Your Material: What metal are you cutting? Is it thick or thin? Hard or soft?

- Check the Thickness:

- For materials around 1/8 inch (3mm) thick or more (like standard bolts, pipes, angle iron), aim for 24 TPI.

- For materials thinner than 1/8 inch (3mm) or harder metals (like conduit, thin tubing, stainless steel), aim for 32 TPI.

- Prioritize Bi-Metal: For durability and performance on metal, always choose bi-metal blades if your budget allows. HSS is a good second choice. Avoid plain carbon steel for metal cutting.

- Match Blade Length to Frame: Ensure the blade you buy is the correct length for your hacksaw frame (most common are 10-inch and 12-inch blades).

Proper Blade Installation and Tensioning

A blade is only as good as its installation. Here’s how to get it right:

- Select the Correct Blade: Based on the guide above, pick your TPI and material.

- Orient the Teeth: Hacksaw blades have teeth that are angled to cut on the push stroke. When installing the blade, ensure the teeth are pointing away from the handle, in the direction of the push.

- Insert the Blade: Place one end of the blade into the hook at the front of the hacksaw frame. Then, flex the frame slightly by pulling the handle towards you and hook the other end of the blade onto the pin at the handle end.

- Tension the Blade: This is crucial! Most modern hacksaws have a tensioning knob or screw. Tighten it until the blade is taut. A properly tensioned blade should make a “ping” sound when flicked, like a guitar string. It should not be slack. An under-tensioned blade can bend, break, or jump out of the frame, causing injury. An over-tensioned blade can also break. Aim for firm but not overly stretched. For reference, the Popular Mechanics guide on using a hacksaw emphasizes proper tension for safety and effectiveness.

Hacksaw Blade Tooth Per Inch (TPI) Rule of Thumb

A simple rule to remember for choosing the right TPI is:

For best results, always have at least two, and preferably three, teeth in contact with the material you are cutting.

This rule helps prevent teeth from stripping or snagging:

- Too few teeth (low TPI) on thin material: The large gaps between teeth mean only one tooth might be cutting at a time, leading to snagging and breakage.

- Too many teeth (high TPI) on thick material: The fine teeth will clog up with metal shavings, making cutting slow and inefficient, and the blade can overheat.

Cutting Techniques for Clean Metal Cuts

Even with the best blade, technique matters! Here’s how to make your cuts smooth and efficient:

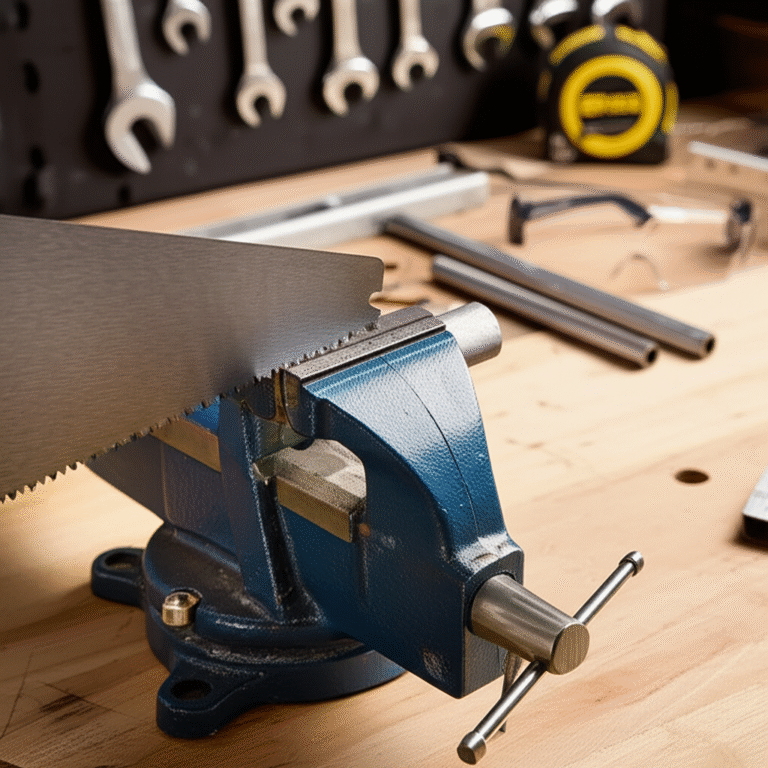

- Secure Your Workpiece: Use a vise or clamps to hold the metal firmly in place. Any movement will make cutting difficult and dangerous. Position the workpiece so the cut is just past the jaws of the vise, providing support right up to the cutting line.

- Start the Cut: Place the blade on your marked cutting line. To prevent the blade from slipping, you can create a small notch with a file or place the blade against a sturdy object (like the edge of your vise) to start the cut. Begin with a few gentle, short strokes, guiding the blade with your fingers on the back of the blade (carefully!).

- Use the Full Blade Length: Don’t just saw back and forth in a small area. Use long, smooth strokes, engaging as much of the blade as possible. This distributes the cutting action, keeps the blade cooler, and makes the job easier.

- Apply Steady Pressure: Let the blade do the work. Apply firm, consistent pressure on the push stroke (when the teeth are cutting) and ease up on the pull stroke. Avoid forcing the saw.

- Maintain a Straight Angle: Keep the hacksaw frame perpendicular to the workpiece to ensure a straight, square cut.

- Clear Debris: Occasionally, stop and clear away metal shavings (swarf) from the cut line and blade. This prevents clogging and makes cutting smoother. A brush or compressed air works well.

- Lubrication (Optional but Recommended): For harder metals or longer cuts, a bit of cutting fluid or oil can help reduce friction, keep the blade cool, and extend its life. Apply it directly to the cutting line.

Common Hacksaw Blade Mistakes to Avoid

Even experienced DIYers can make these mistakes. Being aware of them will save you frustration and potential injury:

- Using the Wrong TPI: This is the most common error. Using a coarse blade on thin metal or a fine blade on thick metal leads to poor results.

- Under-Tensioning the Blade: A loose blade will bend, skip, and break easily. Always ensure it’s properly tensioned.

- Over-Tensioning the Blade: While less common, extreme tension can also cause the blade to snap.

- Forcing the Saw: Hacksaws are designed for steady, controlled strokes. Pushing too hard will bend the blade, strip teeth, and make the cut messy.

- Not Securing the Workpiece: If your material moves during the cut, you’ll get an inaccurate, rough cut, and it can be dangerous.

- Using Old, Dull Blades: Dull blades require more force, generate more heat, and produce rougher cuts. Replace blades when they feel like they’re not cutting efficiently anymore.

- Cutting on the Pull Stroke: Remember, hacksaws cut on the push stroke. Trying to cut on the pull stroke will only damage the teeth and make the job harder.

Blade Lifespan and Replacement

Hacksaw blades are consumables, meaning they wear out and need to be replaced. The lifespan of a blade depends on several factors:

- Material Being Cut: Harder metals and thicker materials will wear out blades faster.

- Blade Quality: Bi-metal blades last significantly longer than HSS or carbon steel blades.

- Technique: Proper tensioning, not forcing the saw, and using the correct TPI all contribute to a longer blade life.

When to Replace Your Blade:

- The blade feels like it’s “skipping” or not biting into the metal.

- You have to apply excessive force to make a cut.

- The cuts are becoming rough and uneven.

- You notice several broken teeth.

Replacing a hacksaw blade is straightforward. Once you’ve removed the old blade (always ensure the frame is de-tensioned first!), simply insert a new one following the installation steps mentioned earlier. Keeping a few spare blades of your most-used TPIs on hand is always a good idea.

Frequently Asked Questions (FAQ)

What is the best TPI for cutting all metals?

There isn’t one single TPI that’s best for all metals. However, a 24 TPI bi-metal blade is the most versatile and works well for a wide range of common metals like steel, copper, and brass. For thinner or harder metals like stainless steel or conduit, a 32 TPI blade is better.

Can I use a hacksaw blade on wood?

While you can technically cut wood with a hacksaw blade, it’s not recommended. Hacksaw blades are designed for metal and have fine teeth that will clog easily with wood fibers, resulting in a very slow, messy cut. Wood saws or coarse-tooth hacksaw blades (18 TPI or lower) are much better suited for wood.

How tight should a hacksaw blade be?

A hacksaw blade should be tensioned until it is taut, like a guitar string. When flicked, it should make a clear “ping” sound. It shouldn’t be slack, as this can cause it to bend or break. However, avoid over-tightening, which can also lead to breakage. Most hacksaws have a tensioning screw or knob to achieve the right tension.

How do I know when my hacksaw blade is dull?

You’ll know a blade is dull when you have