For cutting hardened steel with a hacksaw, choose a bi-metal blade with a high TPI (Teeth Per Inch) count, ideally 24 TPI or higher. This combination provides the durability and fine teeth needed to effectively cut through tough, hardened metal without damaging the blade.

Ever faced a piece of metal that just wouldn’t budge with your trusty hacksaw? You’re not alone! Cutting hardened steel can feel like trying to saw through a brick. It’s frustrating, time-consuming, and can even lead to a broken blade or a sore arm if you’re using the wrong setup. But don’t worry, there’s a simple secret to tackling this tough material. With the right hacksaw blade and a few smart techniques, you can make those stubborn cuts cleanly and efficiently. We’ll walk you through everything you need to know, from picking the perfect blade to mastering the cutting motion. Get ready to conquer hardened steel like a pro!

Why is Cutting Hardened Steel Tricky?

Hardened steel is specifically treated to be incredibly strong and durable. This makes it excellent for tools, machinery parts, and anything that needs to resist wear and tear. However, this very hardness is what makes it so challenging to cut with a standard hacksaw blade. Regular blades can quickly become dull, teeth can strip, and you might end up with little more than sparks and frustration. The key to success lies in understanding the properties of hardened steel and matching them with the right cutting tool.

Understanding Hacksaw Blades: The Basics

Before we dive into hardened steel, let’s quickly cover what makes a hacksaw blade work. Hacksaw blades are thin, flexible strips of metal with sharp teeth along one edge. They come in various lengths, widths, and, most importantly, different tooth configurations. The number of teeth per inch (TPI) is a crucial factor. A higher TPI means smaller, more numerous teeth, which are generally better for cutting thinner materials or harder metals for a smoother finish. A lower TPI means larger, fewer teeth, which are good for cutting thicker, softer metals faster.

When you’re cutting, the teeth on the blade do the work, shaving away small amounts of material with each stroke. The angle and sharpness of these teeth, along with the material’s hardness, determine how effectively the blade cuts.

The Best Hacksaw Blade for Hardened Steel: What to Look For

When you need to cut hardened steel, you can’t just grab any old blade. You need something specialized. Here’s what makes a hacksaw blade suitable for this tough job:

- Material: The blade itself needs to be made of a material that can withstand the hardness of the steel you’re cutting.

- Tooth Design: The shape and spacing of the teeth are critical for efficient cutting and preventing the blade from getting damaged.

- Flexibility: A blade that is too stiff can snap under pressure.

Let’s break down the specifics:

1. Bi-Metal Blades: The Champion Choice

For hardened steel, your absolute best bet is a bi-metal hacksaw blade. What does “bi-metal” mean? It means the blade is made from two different types of metal. The cutting edge, where the teeth are, is made from a high-speed steel (HSS). HSS is extremely hard and can hold a sharp edge even when subjected to the friction and heat generated by cutting tough materials. The rest of the blade, the body, is made from a more flexible spring steel. This combination gives you the best of both worlds: a super-hard cutting edge that stays sharp, and a flexible body that prevents the blade from snapping.

You can find bi-metal blades at most hardware stores. They often have “bi-metal” printed on them, or you might see them advertised for cutting metal. For hardened steel, look for ones specifically recommended for tougher metals.

2. Tooth Count (TPI): Go Fine!

The TPI of a hacksaw blade is super important. For hardened steel, you want a high TPI. This means more teeth, and those teeth are smaller and sharper. Here’s why:

- Smoother Cut: More teeth engage with the material at any given time, leading to a smoother, more controlled cut.

- Reduced Heat: Smaller teeth remove less material per stroke, which generates less friction and heat. This is crucial because excessive heat can quickly dull even a good blade.

- Less Stripping: High TPI blades are less likely to have their teeth stripped or “loaded” (where metal shavings clog up the teeth) when cutting hard materials.

What TPI should you aim for? For hardened steel, a TPI of 24 or even 32 TPI is ideal. While 18 TPI is common for general metal cutting, it’s usually too coarse for hardened steel and will likely result in poor performance and rapid wear.

3. Blade Length and Thickness

Standard hacksaw blades are typically 10 or 12 inches long. This is generally fine for most DIY projects. Blade thickness also plays a role, but for hardened steel, the material composition and TPI are far more critical. A good quality bi-metal blade, even if it’s a standard length, will perform well.

Table: Choosing the Right Blade for Different Metals

To give you a clearer picture, here’s a quick guide:

| Material to Cut | Recommended TPI | Blade Material | Notes |

|---|---|---|---|

| Soft Metals (e.g., Aluminum, Copper) | 14-18 TPI | Carbon Steel or Bi-Metal | Faster cutting, coarser finish. |

| General Metals (e.g., Steel Pipe, Rebar) | 18-24 TPI | Bi-Metal | Good balance of speed and finish. |

| Hardened Steel (e.g., Tool Steel, Hardened Bolts) | 24-32 TPI | Bi-Metal (HSS Teeth) | Slow, controlled cutting for durability. |

| Thick Materials (any type) | Lower TPI (e.g., 14-18 TPI) | Bi-Metal | More tooth engagement for efficiency. |

| Thin Materials (e.g., Sheet Metal) | Higher TPI (e.g., 24-32 TPI) | Bi-Metal | Prevents snagging and tooth stripping. |

Essential Tools and Preparation

Before you start cutting, make sure you have everything you need. Proper preparation makes the job much easier and safer.

- Hacksaw Frame: Ensure your hacksaw frame is sturdy and allows you to tension the blade properly. A loose blade will make cutting difficult and can cause it to break.

- Hacksaw Blade: A new, high-quality bi-metal blade with 24-32 TPI.

- Safety Glasses: Absolutely essential! Metal shards can fly off unexpectedly.

- Work Gloves: Protect your hands from sharp edges and the blade.

- Clamps or Vise: You need to secure the workpiece firmly. This is non-negotiable for safety and effective cutting. A good vise is ideal.

- Marker: To mark your cut line.

- Cutting Fluid or Lubricant (Optional but Recommended): For hardened steel, a lubricant can significantly reduce friction and heat, extending blade life and making cutting smoother. Cutting oil, WD-40, or even a bit of bar soap can help.

- Bench Grinder or File: To deburr the cut edge afterward.

You can learn more about basic metalworking safety from resources like the Occupational Safety and Health Administration (OSHA), which provides guidelines for safe tool use in various environments.

Step-by-Step Guide: Cutting Hardened Steel with Your Hacksaw

Now that you have your blade and your tools ready, let’s get cutting!

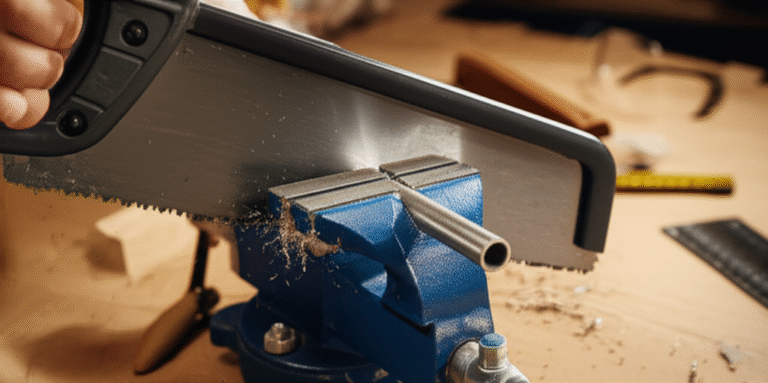

Step 1: Secure Your Workpiece

This is the most important step for safety and success. Clamp the hardened steel firmly in a vise or use sturdy clamps to hold it securely to a workbench. The material should not move at all when you apply pressure. If you’re cutting a bar, position it so that the cut line is as close to the vise jaws as possible. This minimizes vibration and makes the cutting process more efficient.

Step 2: Install the Hacksaw Blade Correctly

Fit your new bi-metal blade into the hacksaw frame. Make sure the teeth are facing the correct direction – away from the handle, so they cut on the push stroke. Tension the blade properly. It should be tight, like a guitar string. If it’s too loose, it will bend and break easily. If it’s too tight, you risk damaging the frame or the blade itself.

Pro Tip: A properly tensioned blade will make a “ping” sound when plucked, similar to a guitar string. A dull thud indicates it’s too loose.

Step 3: Mark Your Cut Line

Use a marker to clearly draw a line where you want to cut. This line will be your guide. For very precise cuts, you might want to use a scribe or a metal scribe to etch a shallow groove along your line. This groove will help guide the initial starting of the cut.

Step 4: Start the Cut – The Tricky Part!

Starting a cut on hardened steel can be the most challenging part. Here’s how to do it:

- Create a Notch: Place the blade on your marked line. Use your thumb or a small file to create a tiny notch or groove where you want to start. This gives the blade teeth something to grip onto.

- Use Lubricant: Apply a bit of cutting fluid or lubricant to the marked line. This will help the blade glide more smoothly and reduce friction.

- Gentle Start: Begin with very light pressure and short, controlled strokes. Focus on making a shallow groove first. Don’t try to cut through a lot of material with these initial strokes.

- Angle the Blade: Hold the hacksaw at a slight angle (around 45 degrees) to start the cut. Once you have a small kerf (the groove made by the blade), you can gradually bring the saw to a more perpendicular angle (90 degrees) to the workpiece.

Step 5: The Cutting Motion – Power and Precision

Once you’ve established a small groove, you can start cutting properly:

- Use the Full Blade: Make long, smooth strokes, using as much of the blade’s length as possible. This distributes the wear evenly across all the teeth.

- Apply Steady Pressure: Apply firm, consistent pressure on the push stroke (when the teeth are cutting). Ease up on the pull stroke.

- Let the Blade Do the Work: Don’t force the saw. Let the sharp teeth do the cutting. Pushing too hard will only overheat the blade, dull the teeth, and potentially break the blade.

- Keep it Lubricated: Periodically reapply your cutting fluid or lubricant. This is especially important for hardened steel.

- Clear Chips: If you notice metal shavings (chips) building up in the kerf, stop and clear them out. You can use a brush or compressed air. Clogged teeth don’t cut well.

Step 6: Finishing the Cut

As you get close to cutting all the way through, reduce your pressure slightly. This prevents the piece you’re cutting off from breaking away suddenly and potentially damaging the end of your cut or your workpiece. Support the piece being cut off as you finish.

Step 7: Deburr the Edges

After the cut is complete, the edges of the metal will likely be sharp and have burrs (small, rough edges). Use a metal file or a bench grinder to smooth down these sharp edges. This makes the workpiece safer to handle and prepares it for any further work.

Tips for Maximizing Blade Life

Hacksaw blades, even good bi-metal ones, aren’t immortal, especially when cutting tough materials. Here are some tips to make yours last longer:

- Always use a bi-metal blade for hardened steel.

- Ensure the blade is properly tensioned.

- Use cutting fluid or lubricant.

- Don’t force the saw; let the teeth cut.

- Use long, smooth strokes, engaging the full blade.

- Keep the workpiece securely clamped.

- Replace the blade as soon as you notice it slowing down or struggling. A dull blade can damage your workpiece and is more likely to break.

When to Consider Other Tools

While a hacksaw is a fantastic tool for many jobs, there are times when hardened steel might be better tackled with a different approach, especially for very thick or very hard pieces, or if you need to make many cuts.

- Angle Grinder with a Cut-Off Wheel: For thicker stock or when speed is essential, an angle grinder with a thin metal cut-off wheel can be much faster. However, this requires more safety precautions and generates more heat and sparks.

- Reciprocating Saw (Sawzall): With the right metal-cutting blade, a reciprocating saw can also be effective.

- Band Saw: For precise, repeatable cuts on harder materials, a metal-cutting band saw is ideal, but this is typically a workshop tool.

- Abrasive Chop Saw: These are designed for cutting metal and can handle hardened steel efficiently.

For small DIY tasks, home repairs, or hobby projects where precision and control are key, a hacksaw with the correct blade is often the most accessible and manageable option. It’s also a great way to develop fundamental metalworking skills.

Frequently Asked Questions (FAQ)

Q1: Can I use a regular hacksaw blade on hardened steel?

A1: It’s highly discouraged. Regular carbon steel blades will dull very quickly, may not cut at all, and can easily break when trying to cut hardened steel. Bi-metal blades with high TPI are specifically designed for this purpose.

Q2: How do I know if my steel is hardened?

A2: Hardened steel is typically used for items that need to be very strong and wear-resistant, such as tools (chisels, files), springs, certain bolts, and machine parts. If a regular hacksaw blade struggles significantly or sparks excessively, it’s a good indicator you’re dealing with hardened steel.

Q3: Is it okay if the blade gets hot while cutting?

A3: Some heat is unavoidable due to friction. However, excessive heat can quickly ruin your blade. Using a cutting fluid or lubricant and ensuring you’re not forcing the saw will help manage heat. If the blade feels too hot to touch, you’re generating too much heat.

Q4: My new blade isn’t cutting well. What could be wrong?

A4: Several things could be the issue: the blade might not be tensioned correctly, you might be forcing the saw instead of letting the teeth cut, the blade might be the wrong type for the material (e.g., too low TPI), or the material itself might be exceptionally hard. Double-check your blade tension and your cutting technique.

Q5: How many cuts can I expect from one hacksaw blade on hardened steel?

A5: This varies greatly depending on the hardness of the steel, the quality of the blade, and your technique. A good bi-metal blade might last for dozens of cuts on moderately hardened steel, but could dull much faster on extremely hard alloys. It’s best to replace a blade when you notice a significant decrease in cutting speed or an increase in effort required.

Q6: What does TPI stand for?

A6: TPI stands for “Teeth Per Inch.” It’s a measure of how many teeth are on one inch of the hacksaw blade. A higher TPI means more teeth and a finer cut, which is generally better for harder materials.

Conclusion

Cutting hardened steel with a hacksaw might seem daunting at first, but with the right knowledge and tools, it’s a perfectly manageable task. Remember, the secret lies in using a bi-metal blade with a high TPI (24-32 TPI), securing your workpiece firmly, and employing a smooth, steady cutting motion with appropriate lubrication. Don’t rush the process; let