Yes, power hacksaws are incredibly good and often essential for anyone needing to cut metal efficiently and accurately. They offer significant advantages in speed, precision, and ease of use over manual methods, making them a proven valuable tool for serious DIYers and professionals alike.

Have you ever tried to cut a piece of metal with a regular hacksaw? It can be a real workout, right? You might get the job done, but it often takes a lot of time, effort, and sometimes the cut isn’t as straight or clean as you’d hoped. This is where many DIYers and hobbyists find themselves wondering if there’s a better way. If you’re cutting metal regularly, even for small projects, you’ve probably asked yourself: “Are power hacksaws any good?” The answer is a resounding yes! They can transform your metalworking experience, making tough cuts manageable and giving you professional-looking results with much less sweat. Let’s dive into why these machines are so fantastic and how they can become your go-to tool for metal fabrication.

Why Consider a Power Hacksaw? The Cutting Edge of Metalwork

When you’re tackling a DIY project that involves metal, whether it’s building a custom workbench, repairing a fence, or crafting a unique metal art piece, the cutting process is often the first major hurdle. Manual hacksaws are great for small, occasional tasks, but they have their limits. They require significant physical effort, can be slow, and achieving perfectly straight cuts, especially on thicker materials, can be challenging. This is where the power hacksaw steps in, offering a robust solution that makes metal cutting feel less like a chore and more like a precise operation.

Think of it this way: a manual hacksaw is like a hand drill, and a power hacksaw is like a drill press. Both do the same basic job, but the latter offers vastly superior control, speed, and accuracy. Power hacksaws are designed specifically for cutting metal, using a powered reciprocating blade that moves back and forth with consistent force and speed. This automation means you can achieve cleaner, straighter cuts more quickly and with far less physical exertion. For anyone serious about metalworking, from the weekend warrior in their garage to the small fabrication shop, a power hacksaw isn’t just a convenience; it’s often an essential piece of equipment that dramatically improves efficiency and the quality of the finished product.

Understanding the Power Hacksaw: How It Works

At its core, a power hacksaw is a mechanized version of the manual hacksaw you might be familiar with. Instead of you pushing and pulling the blade, a motor drives the blade’s back-and-forth motion. This might sound simple, but the engineering behind it makes a huge difference. Here’s a breakdown of the key components and how they work together:

- The Blade: Just like a manual hacksaw, the power hacksaw uses a long, thin, toothed blade. These blades are typically made of high-speed steel (HSS) or bi-metal, designed to withstand the heat and friction generated during metal cutting. The teeth are angled and spaced to efficiently remove material.

- The Frame/Bow: This is the part that holds the blade taut. In a power hacksaw, the frame is robust and designed to withstand the forces of the motor and the cutting action. It moves up and down.

- The Drive Mechanism: This is the heart of the machine. An electric motor powers a system of gears and linkages that convert the motor’s rotation into the reciprocating (back-and-forth) motion of the blade.

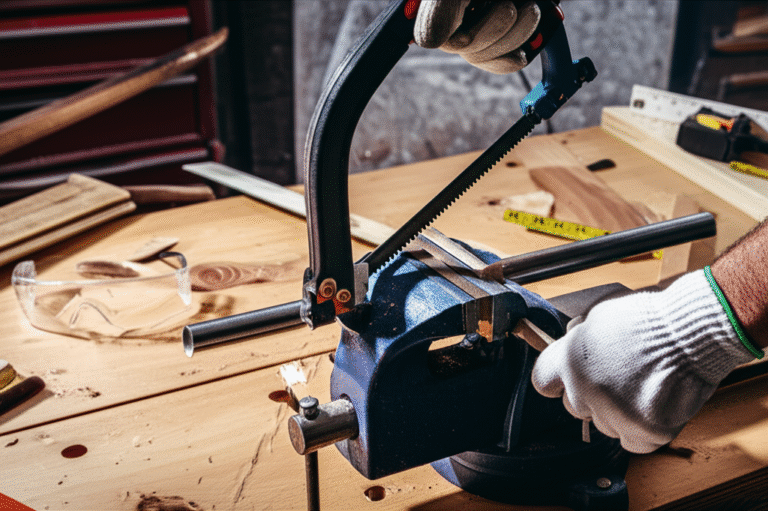

- The Vice: Essential for holding your material securely in place. A good vice on a power hacksaw is crucial for preventing movement during the cut, which ensures accuracy and safety.

- Coolant System (Optional but Recommended): Many power hacksaws include a system to deliver cutting fluid or coolant to the blade and workpiece. This is vital for reducing heat, lubricating the cut, and prolonging blade life.

The magic happens when the motor engages. It drives the blade downwards through the material on the cutting stroke and lifts it slightly on the return stroke. This lifting action, called “backlash,” is important because it prevents the blade teeth from dragging and dulling on the material during the non-cutting stroke. The consistent, controlled motion of the power hacksaw is what allows for those smooth, precise cuts that are so hard to achieve by hand.

Power Hacksaw vs. Manual Hacksaw: A Comparison

To truly appreciate the value of a power hacksaw, it’s helpful to see how it stacks up against its manual counterpart. While the manual hacksaw is a versatile and accessible tool, the power hacksaw excels in specific areas, making it the superior choice for many metalworking tasks.

Here’s a table outlining the key differences:

| Feature | Manual Hacksaw | Power Hacksaw |

|---|---|---|

| Speed | Slow, depends on user’s strength and endurance. | Significantly faster; motor drives the cutting action. |

| Effort Required | High physical effort needed for sustained cutting. | Minimal physical effort; the machine does the work. |

| Cut Quality & Accuracy | Can be good with practice, but prone to wavering on long cuts. | Consistently straight and clean cuts, especially on thicker materials. |

| Material Capacity | Limited by blade length and user strength; best for smaller stock. | Can handle much larger and thicker materials, depending on machine size. |

| Blade Life | Can be shortened by improper technique or overheating. | Generally longer due to controlled cutting and often coolant use. |

| Cost | Very low. | Higher initial investment, but cost-effective for frequent use. |

| Noise | Minimal. | Can be noisy, depending on the model and material. |

| Portability | Highly portable. | Generally stationary, though smaller benchtop models exist. |

As you can see, for tasks requiring speed, precision, and the ability to cut larger or harder materials, the power hacksaw is the clear winner. It’s an investment that pays off in saved time, reduced frustration, and better results.

When is a Power Hacksaw Essential?

So, are power hacksaws always necessary? Not necessarily for every single cutting task. If you’re just cutting a small bolt occasionally, a manual hacksaw will do just fine. However, there are several scenarios where a power hacksaw moves from being a “nice-to-have” to a genuine essential:

- Frequent Metal Cutting: If your projects regularly involve cutting metal stock, tubing, or pipe, the time and effort saved by a power hacksaw are immense.

- Thicker or Harder Metals: Cutting through solid steel bars, thick-walled tubing, or hardened alloys with a manual saw is incredibly difficult and time-consuming. A power hacksaw makes these tasks manageable.

- Need for Precision: When the accuracy of your cuts is critical for assembly or aesthetics, the consistent action of a power hacksaw ensures straighter, cleaner cuts every time.

- Production Work: For small workshops or hobbyists who produce multiple identical parts, a power hacksaw significantly speeds up the process and ensures consistency.

- Ergonomics and Health: For individuals who may have physical limitations or want to avoid repetitive strain injuries, a power hacksaw reduces the physical demand of cutting.

Consider the Occupational Safety and Health Administration (OSHA) guidelines on machine guarding and safe operation. While these often apply to industrial settings, the principles of using the right tool for the job and ensuring safe operation are paramount for any DIYer. A power hacksaw, when used correctly, can actually be safer than a manual hacksaw for certain tasks because it offers more controlled cutting and reduces the risk of the blade binding or snapping unexpectedly due to user error.

Choosing the Right Power Hacksaw for Your Needs

Power hacksaws come in various sizes and configurations, from small benchtop units to large industrial machines. For the home hobbyist or DIYer, you’ll likely be looking at benchtop or floor-standing models. Here’s what to consider:

Key Features to Look For:

- Motor Power: More powerful motors can handle tougher materials and longer cutting cycles.

- Blade Size and Stroke Length: This determines the maximum size of material you can cut. Longer stroke lengths can also increase cutting speed.

- Blade Speed Control: Variable speed settings allow you to optimize the cutting speed for different materials. Softer metals might need slower speeds, while harder metals can often be cut faster.

- Coolant System: A built-in coolant system is a significant advantage for extending blade life and improving cut quality.

- Vice Type and Jaw Width: Ensure the vice can securely grip the materials you plan to cut and has a sufficient jaw width.

- Mitre Cutting Capability: Some models allow you to angle the vice to make angled cuts, which is useful for frames or complex assemblies.

- Construction Quality: Look for a sturdy frame and base to minimize vibration and ensure stability. Cast iron construction is generally a good indicator of durability.

Types of Power Hacksaws:

- Benchtop Power Hacksaws: These are smaller, more compact units designed to sit on a workbench. They are ideal for smaller workshops or for those with limited space. They are generally suitable for cutting smaller stock and lighter-duty tasks.

- Floor-Standing Power Hacksaws: These are larger, more robust machines that offer greater capacity and power. They are better suited for cutting larger metal pieces, harder materials, and for more demanding workshop environments.

When making your choice, think about the types of projects you’ll be doing most often. If you’re cutting mostly 1-inch steel bar, a smaller benchtop model might suffice. If you anticipate cutting larger pipes or thicker plates, a floor-standing unit will be a better investment.

Getting Started: Setting Up and Using Your Power Hacksaw

Once you’ve chosen your power hacksaw, the next step is to get it set up and ready to cut. Don’t be intimidated; it’s a straightforward process. Safety first, always!

Step-by-Step Guide to Using a Power Hacksaw:

- Read the Manual: Seriously, this is the most important step. Every machine is slightly different. Familiarize yourself with your specific model’s controls, safety features, and maintenance requirements.

- Secure the Machine: If it’s a benchtop model, ensure it’s bolted to a sturdy workbench. For floor-standing models, make sure it’s on a level, stable surface.

- Install the Blade:

- Ensure the saw is unplugged.

- Loosen the blade tensioning handle.

- Insert the blade into the frame, ensuring the teeth are pointing forward (in the direction of the cut).

- Tighten the blade tensioning handle until the blade is taut. It should “ping” when flicked, but not be so tight that it risks snapping. A properly tensioned blade is crucial for a good cut and to prevent blade breakage.

- Select the Right Blade: Blade selection is critical. The general rule of thumb is to have at least two to three teeth in contact with the material being cut.

- Fine-tooth blades (e.g., 24-32 TPI – Teeth Per Inch): Best for thin-walled tubing, sheet metal, and harder metals.

- Coarse-tooth blades (e.g., 14-18 TPI): Best for solid bars, larger diameter stock, and softer metals.

You can find excellent guides on blade selection from reputable metalworking suppliers. For instance, The L.S. Starrett Company, a well-known tool manufacturer, offers detailed guides on choosing the correct hacksaw blade for various materials and applications.

- Position and Secure the Material:

- Place your metal stock into the vice.

- Ensure the material is held firmly and won’t shift during the cut.

- Position the material so that the cut line is just behind the vice jaws, allowing the blade to cut into the material without hitting the vice itself.

- If making a mitre cut, adjust the vice angle accordingly.

- Set Up the Cut:

- Lower the blade manually to the material to ensure it’s aligned correctly for the cut.

- Adjust the automatic downfeed (if your model has one) or prepare to manually control the feed rate.

- Start the Cut:

- Turn on the coolant if equipped.

- Start the motor.

- Let the blade engage the material. Apply light pressure if not using automatic feed. The machine should do most of the work.

- Monitor the cut. Listen for any unusual noises.

- During the Cut:

- Keep the coolant flowing.

- Avoid forcing the blade. Let the machine’s weight and the blade’s sharpness do the work.

- If the blade starts to bind or chatter, you may need to adjust the feed rate, blade tension, or coolant flow.

- Completing the Cut:

- As the cut nears completion, the blade will start to cut through the remaining material.

- The saw’s auto-stop mechanism (if equipped) will shut off the motor when the cut is finished. If not, be ready to turn it off manually to prevent the blade from digging into the supporting surface or the offcut.

- After the Cut:

- Turn off the motor and coolant.

- Carefully remove the cut pieces from the vice.

- Clean up any chips and coolant.

- Inspect the blade for any damage.

Maintenance for Longevity

Like any power tool, your power hacksaw will perform best and last longer with proper maintenance. Here are a few key things to keep in mind:

- Blade Care: Regularly inspect blades for dullness or damage. Replace them promptly. Clean blades after use to remove metal chips and coolant residue.

- Coolant System: Keep the coolant reservoir topped up and clean. Dirty coolant can clog the system and reduce its effectiveness. Follow manufacturer recommendations for coolant types and change intervals.

- Lubrication: Check the manual for any lubrication points on the saw’s moving parts, such as pivot points or gear mechanisms.

- Cleaning: Keep the machine free of metal chips and debris. A brush and compressed air are useful for this.

- Blade Tension: Periodically check and adjust blade tension to ensure it’s always properly taut.

Pros and Cons of Power Hacksaws

To give you a balanced perspective, let’s summarize the advantages and disadvantages:

Pros:

- Speed and Efficiency: Dramatically faster than manual sawing.

- Accuracy and Cleanliness: Produces straight, precise cuts with minimal burrs.

- Reduced Physical Effort: Ideal for users who want to minimize strenuous activity.

- Material Versatility: Can cut a wide range of metals, including thicker and harder types.

- Blade Longevity: Controlled cutting and coolant use extend blade life compared to manual methods.

- Consistency: Excellent for producing multiple identical parts.

Cons:

- Initial Cost: Higher upfront investment compared to manual tools.

- Space Requirement: Takes up more space than a hand hacksaw.

- Noise: Can be noisy during operation.

- Power Requirement: Needs access to electricity.

- Maintenance: Requires more maintenance than a simple hand tool (e.g., coolant, blade checks).

Frequently Asked Questions (FAQ)

Q1: How do I choose the right blade TPI for my power hacksaw?

A1: The general rule is to have at least two to three teeth in contact with the material at all times. For thin materials or hard metals, use a finer pitch (higher TPI, e.g., 24-32 TPI). For thicker, softer metals, use a coarser pitch (lower TPI, e.g., 14-18 TPI).

Q2: Is a power hacksaw safe to use for a beginner?

A2: Yes, power hacksaws can be very safe for beginners, provided they read the manual, understand the machine’s operation, and always follow safety precautions like wearing safety glasses. The automated cutting action is often more controlled than manual sawing, reducing the risk of blade binding or snapping.

Q3: Do I really need a coolant system?

A3: While not strictly mandatory for all cuts, a coolant system is highly recommended. It significantly reduces friction and heat, which prolongs blade life, improves cut quality, and helps prevent metal from overheating and deforming.

Q4: How often should I change the blade on my power hacksaw?

A4: Blade life varies greatly depending on the material being cut, the blade quality, and how the saw is used. You should change the blade when you notice a significant decrease in cutting speed, increased effort is required, or the cut quality deteriorates. Inspecting the blade for dull or broken teeth is a good practice before each use.

Q5: Can I cut aluminum or plastic with a power hacksaw?

A5: Yes, you can cut aluminum and many plastics with a power hacksaw. However, you’ll generally want to use a finer-tooth blade and possibly a slower speed setting to prevent the material from melting or gumming up the blade. Always test on a scrap piece first.

Q6: What’s the difference between a power hacksaw and a bandsaw?

A6: A power hacksaw uses a single, straight blade that moves back and forth. A bandsaw uses a continuous loop of blade that moves in one direction. Bandsaws are often faster and can make curved cuts, while power hacksaws are typically better for straight, heavy-duty cuts on solid stock and are generally more robust for repetitive straight cuts.

Conclusion: Your Metal Cutting Companion

So, to circle back to our initial question: “Are power hacksaws any good?” The answer is an unequivocal yes. For anyone who finds themselves regularly cutting metal, from hobbyists building intricate projects to homeowners tackling DIY repairs, a power hacksaw is a proven essential tool. It transforms a labor-intensive, often frustrating task into a precise, efficient operation.

By understanding how they work, choosing the right model for your needs, and following safe operating procedures, you can unlock a new level of capability in your workshop. The clean, straight cuts you’ll achieve will not only make your projects look more professional but will also make the entire building or repair process smoother and more enjoyable. Don’t let metal cutting be a barrier to your creativity or your home maintenance tasks. Embrace the power and precision of a power hacksaw, and you’ll wonder how you ever managed without one.