A power hacksaw offers significant advantages for DIYers and makers, providing faster, more precise, and less physically demanding cuts on metal, plastic, and wood compared to manual hacksaws. It’s an excellent investment for anyone tackling frequent or tough cutting tasks.

Are you tired of struggling with a manual hacksaw, especially when you have a lot of cutting to do or the material is tough? You’re not alone! Getting a clean, straight cut can feel like a real challenge. It can be frustrating, time-consuming, and even a bit tiring. But what if there was a way to make those cuts easier, faster, and much more accurate? If you’re looking to upgrade your workshop or just make your DIY projects smoother, understanding the benefits of a power hacksaw is your first step. We’ll walk through exactly why this tool is a game-changer for anyone who works with materials like metal, plastic, and even wood.

What is a Power Hacksaw and How Does it Work?

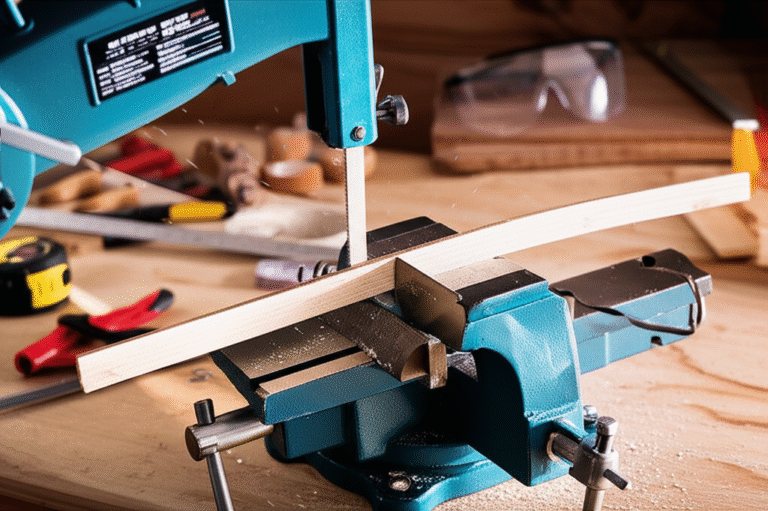

A power hacksaw, also known as a bandsaw or metal-cutting bandsaw (though the term “hacksaw” often refers to the reciprocating blade action), is a mechanized tool designed for cutting various materials, most commonly metals, but also plastics and wood. Unlike a manual hacksaw that relies on your arm strength and a back-and-forth motion, a power hacksaw uses an electric motor to drive a blade through the material. This motor powers a mechanism that moves the blade in a continuous, controlled stroke, or in the case of a bandsaw, a continuous loop.

The core components of a typical power hacksaw include:

- Motor: Provides the power to drive the blade.

- Blade: A reciprocating or band blade made of hardened steel, often with specific tooth configurations for different materials.

- Frame/Arm: Holds the blade and moves it through the material.

- Workpiece Clamp: Secures the material being cut to ensure stability and accuracy.

- Coolant System (optional but common): Helps to lubricate the blade and workpiece, reducing heat and extending blade life.

The motor powers a drive system, which can be a crank mechanism for reciprocating saws or a wheel system for bandsaws. This system moves the blade at a consistent speed and stroke length. The operator positions the material under the blade and activates the saw. The blade then cuts through the material with a steady, powerful motion. This automation significantly reduces the physical effort required and improves the consistency of the cut.

For a deeper dive into the mechanics of cutting tools, the Occupational Safety and Health Administration (OSHA) provides valuable resources on safe operation and maintenance of various power tools, including cutting equipment.

Key Advantages of Using a Power Hacksaw

So, why make the switch from a trusty manual hacksaw to a power-driven one? The benefits are numerous and can dramatically improve your cutting experience. Let’s break down the proven advantages:

1. Speed and Efficiency

This is perhaps the most immediate and noticeable advantage. A power hacksaw cuts through material much faster than a manual one. The consistent, powered strokes mean you can get through thick metal stock or a pile of plastic pipes in a fraction of the time it would take by hand. This is a huge time-saver, especially for projects that involve a lot of cutting or when you’re on a deadline.

Imagine cutting through a 2-inch solid steel bar. By hand, this could take a significant amount of time and effort, possibly requiring multiple blade changes due to wear. A power hacksaw, with the right blade and settings, can accomplish this in minutes, with less physical strain.

2. Precision and Accuracy

Achieving a perfectly straight and square cut with a manual hacksaw can be tricky, especially for beginners. It requires a steady hand, consistent pressure, and good form. A power hacksaw eliminates much of this variability. The blade moves in a fixed path, and the workpiece is held securely by a vise or clamp. This results in straighter, more accurate cuts, which are crucial for many projects, particularly in metal fabrication and woodworking where tight tolerances are important.

For instance, if you’re building a custom frame or assembling metal components, precise cuts ensure that parts fit together snugly without gaps or misalignments. This reduces the need for secondary finishing or adjustments, saving you time and frustration.

3. Reduced Physical Effort and Fatigue

Manual hacksawing is a physically demanding task. The repetitive motion, the need to apply consistent downward pressure, and the resistance of the material can lead to fatigue, sore muscles, and even injury if not done carefully. A power hacksaw takes the muscle work out of the equation. The motor does the heavy lifting, allowing you to focus on guiding the material and ensuring it’s positioned correctly.

This makes power hacksaws ideal for individuals who may not have the physical strength for extensive manual cutting, or for anyone who wants to complete their projects without feeling exhausted. It opens up more complex projects to a wider range of users.

4. Longer Blade Life

When you use a manual hacksaw, it’s easy to apply too much or too little pressure, or to use an inconsistent stroke. This can lead to premature blade wear, snapping, or teeth stripping. Power hacksaws, especially those with variable speed settings and coolant systems, provide a more controlled cutting action. The consistent speed and lubrication reduce friction and heat buildup, which are major culprits in blade degradation.

A good quality blade on a power hacksaw, used with appropriate settings for the material, can last significantly longer than a blade used for manual cutting. This translates to cost savings over time, as you’ll be replacing blades less frequently.

5. Versatility in Material Cutting

While manual hacksaws are generally used for metal and some plastics, power hacksaws are often designed with specific blades and settings that allow them to cut a wider range of materials with greater efficiency. Many power hacksaws can effectively cut:

- Various Metals: Steel, aluminum, brass, copper, iron, and alloys.

- Plastics: PVC, ABS, acrylic, polycarbonate, and more.

- Wood: Though less common for dedicated wood cutting, some power hacksaws can handle wood, especially with specialized blades.

The ability to switch between different blade types and adjust cutting speed makes a power hacksaw a versatile tool for a workshop that handles diverse projects. For example, a carbide-tipped blade can power through hardened steel, while a fine-tooth blade is perfect for thin-walled tubing or plastics.

6. Improved Safety

While all power tools require careful operation, a power hacksaw can offer improved safety over prolonged manual cutting. By reducing physical strain, it lowers the risk of muscle pulls or strains. Furthermore, the secure clamping mechanism prevents the workpiece from shifting unexpectedly during the cut, which is a common hazard with manual saws. The enclosed nature of some power hacksaw designs also helps to contain sparks and debris.

Always ensure you are wearing appropriate personal protective equipment (PPE), such as safety glasses or a face shield, hearing protection, and gloves, when operating any power tool. For more on tool safety, the National Institute for Occupational Safety and Health (NIOSH) offers comprehensive guidelines on preventing injuries from tools and machinery.

7. Consistent Cut Quality

For projects requiring a professional finish, consistent cut quality is paramount. A power hacksaw delivers this by maintaining a steady blade speed, consistent feed rate (controlled by the operator or an auto-feed mechanism), and secure workpiece holding. This results in smooth, clean edges that often require minimal deburring or finishing.

This consistency is invaluable for hobbyists building models, fabricators creating precise components, or anyone who takes pride in the finish of their work. It eliminates the jagged edges and uneven surfaces that can plague manual cuts.

Power Hacksaw vs. Manual Hacksaw: A Comparison

To truly appreciate the advantages of a power hacksaw, it’s helpful to see how it stacks up against its manual counterpart. Here’s a quick comparison:

| Feature | Power Hacksaw | Manual Hacksaw |

|---|---|---|

| Cutting Speed | Fast | Slow |

| Precision | High | Moderate to High (operator dependent) |

| Physical Effort | Low | High |

| Blade Life | Longer (with proper use and coolant) | Shorter (prone to damage from improper use) |

| Material Versatility | Wide range (metals, plastics, wood with right blade) | Primarily metal, some plastics and wood (limited) |

| Cost | Higher initial investment | Low initial investment |

| Portability | Generally less portable | Highly portable |

| Noise Level | Moderate to High | Low |

| Power Source | Electric motor | Human power |

As you can see, the power hacksaw excels in areas where manual hacksaws can be limiting, particularly for those who perform frequent or demanding cutting tasks.

Choosing the Right Power Hacksaw for Your Needs

When you’re ready to invest in a power hacksaw, consider these factors:

- Material Type: Are you primarily cutting soft metals like aluminum, or harder materials like steel? This will influence the power and blade type you need.

- Cutting Capacity: What is the maximum size of material you’ll need to cut? Check the saw’s cutting dimensions (width and depth).

- Power Requirements: Most power hacksaws run on standard household electricity, but check the amperage draw to ensure your circuit can handle it.

- Features: Look for features like adjustable speed, automatic shut-off, coolant systems, and robust vises.

- Budget: Power hacksaws range from affordable benchtop models to heavy-duty industrial machines.

For home workshop use, a benchtop or portable power hacksaw is often a great starting point. These are more compact and less expensive than larger floor-standing models but still offer significant advantages over manual cutting.

Tips for Using a Power Hacksaw Safely and Effectively

Once you have your power hacksaw, follow these tips to get the best results:

- Read the Manual: Always start by thoroughly reading your tool’s instruction manual.

- Select the Correct Blade: Use a blade with the appropriate TPI (Teeth Per Inch) for the material you are cutting. For metal, a general rule is:

- 14 TPI: For larger sections of metal (over 1 inch)

- 18 TPI: For medium sections of metal (1/2 inch to 1 inch)

- 24 TPI: For thinner metal sections (under 1/2 inch) and tubing

- 32 TPI: For very thin sheet metal and tubing

- Secure the Workpiece: Always clamp your material firmly in the vise. Ensure it’s positioned so the blade will cut cleanly without binding.

- Use Coolant: If your saw has a coolant system, use it! Coolant lubricates the blade, reduces heat, and helps clear chips, extending blade life and improving cut quality.

- Start Slowly: When beginning a cut, especially on thicker materials, start the saw and let it establish a clean kerf (the width of the cut) before letting the blade feed completely.

- Let the Saw Do the Work: Don’t force the blade. Apply steady, light pressure and let the motor and the blade’s teeth do the cutting. Forcing can damage the blade and the saw.

- Maintain the Tool: Keep your power hacksaw clean. Brush away metal chips and debris, and check the blade tension regularly.

- Wear PPE: Always wear safety glasses, hearing protection, and appropriate clothing.

Frequently Asked Questions (FAQ)

Q1: Can a power hacksaw cut wood?

Yes, a power hacksaw can cut wood, but it’s generally not the ideal tool for the job unless you have a specific blade designed for wood. Standard metal-cutting blades will clog quickly and won’t cut wood efficiently. For wood, a miter saw, circular saw, or even a jigsaw would be more appropriate.

Q2: How do I choose the right blade for my power hacksaw?

The key is the TPI (Teeth Per Inch). For metal, more TPI means finer cuts on thinner materials, while fewer TPI is better for thicker materials. Always match the blade’s TPI to the thickness of the material you’re cutting. Check the saw’s manual or the blade manufacturer’s recommendations.

Q3: Is a power hacksaw difficult to set up?

Most benchtop power hacksaws are relatively easy to set up. They typically come pre-assembled or require minimal assembly, like attaching legs or a stand. The main setup involves installing the correct blade and ensuring the power cord is connected to a suitable outlet.

Q4: How much maintenance does a power hacksaw require?

Maintenance is generally straightforward. Keep the saw clean, especially the blade and vise. Regularly check blade tension and replace blades when they become dull. If your saw has a coolant system, ensure it’s kept clean and filled. Lubricating moving parts as per the manufacturer’s instructions is also important.

Q5: What is the difference between a power hacksaw and a bandsaw?

While both are power cutting tools, a power hacksaw typically uses a single, reciprocating blade that moves back and forth. A bandsaw uses a continuous loop of a blade that moves in one direction. Bandsaws are often preferred for their speed and ability to make curved cuts, while power hacksaws are excellent for straight, precise cuts on solid stock and tubing.

Q6: Can a power hacksaw be used for delicate or intricate cuts?

Power hacksaws are primarily designed for straight, robust cuts. For delicate or intricate cuts, especially in thinner materials or those requiring curves, a bandsaw, jigsaw, or scroll saw would be more suitable. The power hacksaw’s strength lies in its efficiency for straight, repeatable cuts.

Q7: What safety precautions should I take when using a power hacksaw?

Always wear safety glasses or a face shield, hearing protection, and sturdy gloves. Ensure the workpiece is securely clamped. Keep your hands away from the blade path. Never reach under the saw while it’s running. Make sure the area around the saw is clear of obstructions and flammable materials.

Conclusion

For hobbyists, makers, and DIYers who regularly tackle projects involving metal, plastic, or even wood, a power hacksaw is an incredibly valuable addition to the workshop. The advantages of increased speed, superior precision, reduced physical strain, and improved cut quality are undeniable. While the initial investment might be higher than a manual hacksaw, the time saved, the frustration avoided, and the professional finish you can achieve make it a worthwhile upgrade.

By understanding how a power hacksaw works and following safe operating practices, you can confidently take on more ambitious projects and achieve cleaner, faster, and more accurate cuts than ever before. It’s a tool that empowers you to work smarter, not harder, and truly elevates the quality of your craftsmanship.