Are Air Compressor Regulators Universal? Yes, but with important caveats. While many regulators share common thread sizes and basic functions, direct interchangeability isn’t guaranteed. This guide will help you understand compatibility and make the right choice for your needs.

So, you’ve got an air compressor, and you’re looking to fine-tune the air pressure for your tools. Maybe you’re inflating tires, running a brad nailer, or even getting ready to winterize your sprinkler system. You might be wondering if that regulator you saw online, or the one your buddy has, will work with your compressor. It’s a common question, and the answer can be a bit tricky. It’s not a simple yes or no. We’re here to break down exactly what you need to know to avoid confusion and make sure you get the right part for your setup. Let’s dive in and get you sorted!

Understanding Air Compressor Regulators: The Basics

An air compressor regulator is a crucial component in any compressed air system. Its primary job is to take the high, often fluctuating pressure from your compressor tank and reduce it to a consistent, usable pressure that your air tools need. Think of it like the volume knob on a stereo – it controls the output. Without a regulator, you’d be blasting your tools with raw, untamed pressure, which could damage them or lead to inconsistent performance.

Why Do We Need Pressure Regulation?

Compressed air from a tank can be anywhere from 90 to over 170 PSI (pounds per square inch), depending on the compressor. However, most air tools operate within a much narrower range. For example:

Brad Nailers: Typically require 70-100 PSI.

Impact Wrenches: Often need 90-120 PSI.

Paint Sprayers: Can range from 30-70 PSI, depending on the type.

Tire Inflators: Usually around 30-60 PSI.

Running a tool at a pressure higher than its recommended setting can cause it to break, leak, or simply not function correctly. Conversely, too low a pressure means the tool won’t have enough power to do its job efficiently. A regulator ensures you’re delivering the right pressure, every time.

So, Are Air Compressor Regulators Universal? Let’s Get Specific.

The short answer is: not entirely. While many regulators are designed with common fittings and general functionality in mind, there are key differences that determine compatibility. It’s less about a universal “one-size-fits-all” and more about finding a regulator that fits your specific compressor’s outlet and your tool’s inlet.

The main factors influencing compatibility are:

Thread Size and Type: This is the most critical aspect.

Flow Rate Capacity: How much air the regulator can handle.

Pressure Range: The maximum inlet and adjustable outlet pressure.

Mounting Style: How it connects to the compressor.

Let’s break these down.

The Crucial Factor: Thread Size and Type

This is where most compatibility issues arise. Air compressor fittings, including those on regulators, typically use NPT (National Pipe Thread) or sometimes BSP (British Standard Pipe) threads. NPT is the standard in North America.

NPT threads are tapered, meaning they get smaller as they go deeper into the fitting. This taper helps create a seal when the threads are tightened.

The most common NPT thread sizes you’ll encounter on air compressor outlets and regulator inlets are:

1/4-inch NPT: This is extremely common on smaller, portable compressors and for the outlet ports on many larger units. It’s also the standard for many common air tool fittings.

3/8-inch NPT: You’ll find this on some mid-sized compressors or as a higher-flow outlet on larger units.

1/2-inch NPT: Less common for direct regulator attachment on smaller units, but can be found on the main tank outlet of larger industrial compressors.

Important Note: While the size (e.g., 1/4-inch) might match, the thread pitch (how many threads per inch) must also be the same for a proper seal. NPT is the standard, but if you’re dealing with imported equipment, you might encounter BSP threads, which are not compatible with NPT without an adapter.

How to Check Your Threads

1. Look at your compressor’s outlet: Where the hose connects to the compressor tank, there will be a fitting.

2. Examine the regulator you’re considering: Look at the inlet fitting.

3. Thread Gauge (Optional but Recommended): The most accurate way is to use a thread gauge. You can purchase these relatively cheaply. They have different sizes and thread pitches that you can match to your existing fitting.

4. Visual Inspection and Measurement: You can often identify the size by looking at the diameter of the fitting. For 1/4-inch NPT, the outside diameter of the male threads is typically around 0.540 inches. For 3/8-inch NPT, it’s around 0.675 inches. However, this can be tricky to measure accurately without calipers.

5. Consult Your Manual: Your air compressor’s owner’s manual should specify the outlet thread size. The regulator’s product description should also list its inlet thread size.

Pro Tip: When in doubt, err on the side of caution. Buying the wrong thread size will result in leaks or a fitting that simply won’t screw on. It’s better to take a moment to verify than to waste time and money on an incompatible part.

Flow Rate: Matching Your Regulator to Your Compressor and Tools

Beyond thread size, the regulator needs to be able to handle the volume of air your compressor produces and your tools consume. This is measured in Cubic Feet per Minute (CFM).

Compressor CFM: Your compressor’s CFM rating indicates how much air it can deliver at a specific pressure (e.g., 5 CFM at 90 PSI).

Tool CFM: Each air tool has a CFM requirement for optimal performance. You can usually find this in the tool’s manual.

A regulator has a maximum flow rate it can handle. If your compressor is producing more air (higher CFM) than the regulator can pass through, the regulator can become a bottleneck, starving your tools of air and potentially causing the regulator itself to overheat or fail.

Example: If your compressor outputs 10 CFM at 100 PSI, and you’re using an impact wrench that requires 5 CFM at 90 PSI, you’ll want a regulator that can easily handle at least 10 CFM at the required pressure.

Table: Typical CFM Requirements for Common Air Tools

| Air Tool | Typical CFM @ 90 PSI |

| :——————- | :——————- |

| Brad Nailer | 0.3 – 2.0 |

| Finish Nailer | 1.0 – 2.5 |

| Framing Nailer | 2.0 – 4.0 |

| Stapler | 0.5 – 2.0 |

| Impact Wrench | 4.0 – 7.0 |

| Air Ratchet | 2.0 – 4.0 |

| Die Grinder | 4.0 – 6.0 |

| Orbital Sander | 8.0 – 12.0 |

| Paint Sprayer (HVLP) | 7.0 – 15.0 |

| Tire Inflator | 1.0 – 5.0 |

Recommendation: Always choose a regulator with a CFM rating that is equal to or higher than your compressor’s output and your most demanding tool’s requirement. It’s generally safe to have a regulator with a higher CFM rating than you need; it just means it won’t be working at its limit.

Pressure Range: Ensuring Safety and Functionality

Regulators are rated for a maximum input pressure and have an adjustable output pressure range.

Maximum Input Pressure: This is the highest pressure the regulator can safely accept from the compressor tank. Most compressors operate below 200 PSI, so most regulators will have an input rating well above this.

Adjustable Output Pressure Range: This is the range of pressure the regulator can be set to deliver to your tools. Most regulators can be adjusted from around 0-150 PSI or 0-160 PSI.

Crucial Safety Point: Never use a regulator with a maximum input pressure lower than your compressor’s tank pressure. For example, if your compressor goes up to 150 PSI, you need a regulator rated for at least 150 PSI input.

Mounting Styles: How it Attaches

Regulators can be mounted in a few ways:

1. Inline Regulators: These are typically installed directly onto the compressor’s outlet port or onto a manifold. They often have 1/4-inch or 3/8-inch NPT threads.

2. Manifold-Mounted Regulators: Some larger compressors have a built-in manifold with multiple ports. Regulators can screw directly into these ports.

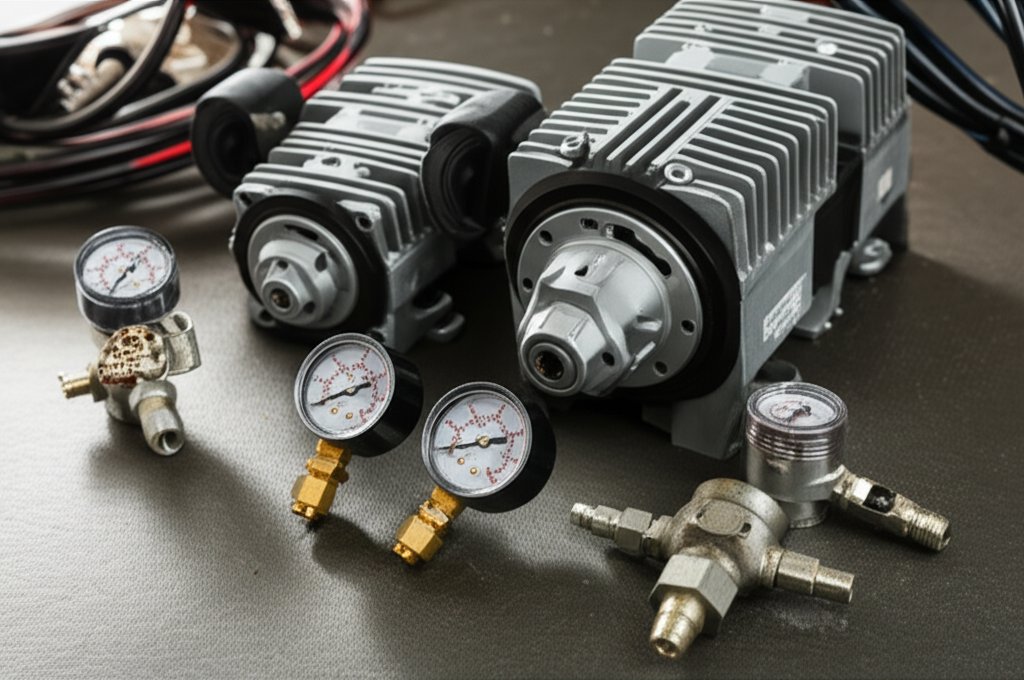

3. Regulator/Filter/Lubricator (FRL) Units: These are often found in industrial settings or for high-end tool use. They combine a regulator, a water separator (filter), and sometimes an oil lubricator into a single unit. These can have larger thread sizes and are often more robust.

Compatibility Check: Ensure the mounting threads on the regulator match the threads on your compressor’s outlet port or manifold.

Types of Air Compressor Regulators

While the core function is the same, there are different types of regulators you might encounter:

Piston Type: Common in many shop-style regulators. They use a spring-loaded piston to control airflow. Generally reliable and offer good pressure control.

Diaphragm Type: Often found in higher-end or more precise regulators. They use a flexible diaphragm, which can offer finer control and better response to pressure changes.

Filter Regulators: These combine a regulator with a water/particle filter. This is highly recommended for protecting your tools, especially sensitive ones like paint sprayers or sanders.

Regulator/Filter/Lubricator (FRL) Units: As mentioned, these are comprehensive units that also add oil to the air stream for tools that require lubrication.

Consideration: For most home and DIY use, a good quality piston-type regulator or a filter regulator will serve you well. For delicate tasks like painting, a filter regulator is almost essential.

Can You Use a Regulator from One Brand on Another Brand’s Compressor?

Yes, if the thread sizes, pressure ratings, and CFM capacities match. Brand names don’t inherently dictate thread compatibility. A 1/4-inch NPT regulator from brand X will thread onto a 1/4-inch NPT outlet on a compressor from brand Y, provided the other specifications are met.

However, some manufacturers might use proprietary fittings or offer integrated regulator systems that are not easily replaced with aftermarket parts. Always check your specific compressor’s design.

Adapters: Bridging the Gap

If you find a regulator you like but the threads don’t quite match, adapters are often available. For example:

1/4-inch NPT Male to 1/4-inch NPT Female: To change the gender of a fitting.

1/4-inch NPT Male to 3/8-inch NPT Female: To adapt a smaller fitting to a larger port.

NPT to BSP Adapters: For converting between thread types (use with caution, as a perfect seal isn’t always guaranteed).

Caution: While adapters can solve thread mismatches, they add extra connection points, which are potential leak sources. They also add length to your air line. It’s always best to find a regulator with the correct direct fitting if possible.

When a Regulator Might NOT Be “Universal”

Non-Standard Threads: As mentioned, BSP or other non-NPT threads can be an issue.

Integrated Regulator Assemblies: Some compressors have regulators built directly into the head or manifold in a way that makes them non-removable or requiring proprietary replacements.

Extreme CFM Requirements: Very high-CFM tools or multiple tools running simultaneously might require specialized, high-flow regulators that aren’t standard on smaller compressor setups.

Specialized Applications: Some industrial or medical applications might use specialized regulators with unique pressure ranges or purity requirements.

Maintaining Your Regulator for Longevity

To ensure your regulator works correctly and lasts a long time:

Keep it Clean: Regularly clean the exterior. If it’s a filter regulator, clean or replace the filter element according to the manufacturer’s instructions.

Protect the Gauge: The pressure gauge is sensitive. Avoid dropping or hitting the regulator.

Bleed Pressure: When not in use, it’s good practice to bleed the pressure from the regulator and hose. This reduces stress on the diaphragm and seals.

Check for Leaks: Periodically check all connections for air leaks using soapy water.

Frequently Asked Questions (FAQ)

What is the most common thread size for air compressor regulators?

The most common thread size for air compressor regulators, especially in North America, is 1/4-inch NPT (National Pipe Thread). This size is prevalent on many portable compressors and air tools.

Can I use a regulator from a Craftsman compressor on a DeWalt compressor?

Yes, if both the compressor’s outlet port and the regulator’s inlet port have the same thread size (e.g., 1/4-inch NPT) and the regulator’s CFM and pressure ratings are suitable for your needs. Brand name doesn’t dictate thread compatibility.

My compressor has a 3/8-inch outlet. Can I use a 1/4-inch regulator?

You can, but you’ll need a 1/4-inch NPT female to 3/8-inch NPT male adapter. However, it’s generally better to use a regulator with a 3/8-inch inlet if your compressor has a 3/8-inch outlet to ensure maximum airflow and avoid potential restrictions.

What does CFM mean for a regulator?

CFM stands for Cubic Feet per Minute and indicates the volume of air a regulator can pass. Your regulator should have a CFM rating that meets or exceeds both your compressor’s output and the requirements of the air tools you plan to use.

Is it important to have a regulator with a built-in filter?

Yes, it’s highly recommended. A filter regulator helps remove water and particulate contaminants from the compressed air, which protects your air tools from damage and ensures better performance, especially for sensitive tools like paint sprayers.

How do I know if a regulator will fit my compressor?

Check the thread size and type on your compressor’s outlet port (usually 1/4-inch or 3/8-inch NPT). Then, check the inlet thread size and type specified for the regulator. Ensure the CFM rating is adequate and the maximum input pressure exceeds your compressor’s tank pressure.

Conclusion: Choosing the Right Regulator for Your Needs

So, are air compressor regulators universal? While the concept of regulating air pressure is universal, the physical fittings and capacity requirements mean that regulators aren’t a simple plug-and-play solution across all compressors and tools. The key is to match the thread size (most commonly 1/4-inch NPT), ensure the CFM rating is sufficient, and verify that the pressure range is appropriate for your compressor and tools.

By understanding these factors, you can confidently select a regulator that will serve you well, protect your valuable air tools, and ensure you get the best performance from your compressed air system. Don’t hesitate to consult your tool manuals and the product specifications for both your compressor and the regulator. A little bit of research now will save you a lot of headaches and ensure your DIY projects run smoothly! Happy compressing!