Yes, you can machine cross drilled rotors, but it’s complex. Special care is needed to avoid damage.

Cross drilled rotors are popular for their improved braking. They have holes drilled through them, allowing better heat dissipation and reduced brake fade. But, machining these rotors can be tricky. The holes can cause the rotor to become weaker if not done correctly.

Therefore, it’s important to understand the process and precautions. In this blog, we’ll explore whether you can machine cross drilled rotors. We will also discuss the pros, cons, and necessary steps to ensure a safe and effective outcome. Let’s dive in and see what you need to know.

Introduction To Cross Drilled Rotors

Machining cross drilled rotors is a debated topic. These rotors have holes drilled to improve cooling. Machining them can affect their performance and safety.

Cross drilled rotors are a popular choice for many car enthusiasts. These rotors have holes drilled into them. This design helps in various ways, enhancing performance and safety.What Are Cross Drilled Rotors

Cross drilled rotors have a unique look. They feature multiple holes drilled through the disc. This design helps to dissipate heat. It also reduces brake fade during heavy braking. Cross drilled rotors are often used in high-performance vehicles.Benefits Of Cross Drilled Rotors

Cross drilled rotors offer several benefits. They improve braking performance. The holes allow for better heat dissipation. This helps to keep the brakes cooler. Cooler brakes are more effective and last longer. Cross drilled rotors also help in wet conditions. The holes allow water to escape. This reduces the risk of hydroplaning. The rotors also tend to be lighter. Lighter rotors can improve vehicle handling. Overall, cross drilled rotors provide better braking and performance. “`Machining Cross Drilled Rotors

Machining cross drilled rotors can be a complex task. These rotors have holes drilled through them to improve braking performance. Many drivers wonder if it’s possible to machine these unique rotors. The answer is not simple. It depends on several factors.

Feasibility Of Machining

Machining cross drilled rotors can be feasible in some cases. The condition of the rotor is crucial. If the rotor is too worn or damaged, machining might not be possible. The amount of material that can be removed also matters. Removing too much can weaken the rotor.

It’s essential to check the rotor’s thickness. There are minimum thickness requirements for safe operation. Machining should not bring the rotor below this limit. Always consult a professional for advice.

Challenges In Machining

There are several challenges when machining cross drilled rotors. The holes in the rotor can create uneven surfaces. This can make the machining process tricky. Specialized equipment may be needed to handle the unique shape.

Another challenge is heat. Machining generates heat, which can affect the rotor. Excessive heat can cause warping. This can lead to braking issues. Ensuring proper cooling is vital during the process.

Balancing is also crucial. Cross drilled rotors need to be balanced correctly. Improper balancing can lead to vibrations. This can affect the vehicle’s performance and safety.

In summary, machining cross drilled rotors is possible. But it requires careful consideration and expertise.

Tools And Equipment Needed

When working on cross-drilled rotors, having the right tools and equipment is crucial. The process demands precision and safety to ensure your vehicle’s braking system remains effective. This section will detail the essential tools and safety equipment needed for machining cross-drilled rotors.

Essential Tools

First, you need a high-quality brake lathe. It allows you to machine the rotors accurately. A micrometer is also necessary to measure rotor thickness. This ensures that you do not exceed the minimum thickness. Sandpaper or emery cloth is useful for cleaning the rotor surface before and after machining. Use a torque wrench to ensure the lug nuts are properly tightened. A dial indicator helps in checking rotor runout.

Safety Equipment

Safety should always be a priority. Wear safety glasses to protect your eyes from metal shards. Gloves protect your hands from sharp edges and hot surfaces. A dust mask is essential to avoid inhaling brake dust, which can be harmful. Ear protection, such as earplugs, helps guard against noise from the brake lathe. Make sure your workspace is well-ventilated to minimize the risk of inhaling harmful particles.

Credit: www.youtube.com

Step-by-step Machining Process

Cross drilled rotors are popular for their improved braking performance. Machining them requires a careful, step-by-step process. This ensures the rotors remain effective and safe. Let’s break down the machining process into simple, easy-to-follow steps.

Preparation

Begin by gathering all necessary tools and equipment. Ensure the workspace is clean and well-lit. Inspect the rotors for any visible damage or excessive wear. Clean the rotors thoroughly to remove any dirt or debris. Secure the rotor in the machining tool, making sure it is stable.

Machining Techniques

Use a lathe or a specialized rotor machine for precision. Set the machine to the correct speed and depth for the rotor material. Begin by making light cuts to avoid damaging the cross-drilled holes. Gradually remove material until the rotor surface is smooth.

Check the rotor frequently for uniform thickness. Use a micrometer to ensure accuracy. Finish with a fine cut to achieve a polished surface. Remove the rotor from the machine and inspect it for any imperfections. Clean the rotor again to remove any metal shavings.

Common Issues And Solutions

Machine cross drilled rotors can experience various issues. Knowing the common problems and their solutions can extend their life and improve performance. Addressing these concerns promptly ensures safety and efficiency.

Cracking And Warping

Cracking and warping are common issues with cross drilled rotors. They often result from excessive heat. This heat can cause the metal to expand and contract, leading to cracks. Warping occurs when the rotor is unevenly heated. This can happen during heavy braking.

Solutions:- Use rotors designed to handle high temperatures.

- Ensure proper bedding-in of new brake pads.

- Regularly inspect rotors for signs of damage.

- Replace rotors if cracks or warps are severe.

Uneven Surfaces

Uneven surfaces on cross drilled rotors can cause vibrations. This can lead to a decrease in braking efficiency. It often occurs due to uneven wear or dirt buildup.

Solutions:- Regularly clean the rotors to remove dirt and debris.

- Ensure proper torque when installing the wheels.

- Check for proper alignment of the brake pads.

- Machine the rotors if uneven wear is present.

By addressing these common issues, you can maintain the performance of your cross drilled rotors. Regular maintenance and inspections are key. This ensures the longevity and effectiveness of your braking system.

Expert Tips For Best Results

Cross drilled rotors are popular in performance vehicles. They offer better cooling and braking efficiency. But, machining them can be tricky. To achieve the best results, follow these expert tips.

Maintaining Precision

Precision is key when machining cross drilled rotors. Small errors can cause big issues. Use a high-quality lathe with a sharp cutting tool. Ensure the rotor is securely clamped. This prevents movement during machining.

Measure the rotor thickness before and after machining. Use a micrometer for accuracy. Compare your measurements to the manufacturer’s specifications. If the rotor is too thin, it may fail during use.

Ensuring Durability

Durability is crucial for cross drilled rotors. They must withstand high stress and heat. Avoid removing too much material. This can weaken the rotor and cause cracks.

After machining, inspect the rotor for any signs of damage. Look for cracks around the drilled holes. If you find any, replace the rotor immediately. Safety should always be your top priority.

Balance the rotor properly after machining. An unbalanced rotor can cause vibrations and uneven wear. Use a balancing machine to ensure even weight distribution.

| Tip | Action |

|---|---|

| Precision | Use a high-quality lathe and measure thickness accurately. |

| Durability | Avoid removing too much material and inspect for cracks. |

| Balance | Ensure even weight distribution using a balancing machine. |

Maintenance After Machining

Maintaining cross drilled rotors after machining is crucial for their longevity and performance. Proper upkeep ensures your brakes operate efficiently and safely. Below are essential steps for maintaining these rotors.

Regular Inspections

Conduct regular inspections to check for any wear or damage. Look for cracks, deep grooves, and uneven surfaces. These signs indicate potential issues that need immediate attention. A visual check should be done every 3,000 miles. Use a flashlight to inspect hard-to-see areas.

Cleaning And Care

Keeping your rotors clean is vital. Dirt and debris can cause wear and tear. Use a brake cleaner spray to remove dust and grime. Spray the cleaner on the rotors and use a soft cloth to wipe them down.

Avoid using harsh chemicals that can damage the rotor’s surface. Simple soap and water can be effective for routine cleaning. Dry the rotors thoroughly to prevent rust formation.

Here is a simple cleaning routine:

- Lift the vehicle using a jack.

- Remove the wheels to access the rotors.

- Spray brake cleaner on the rotors.

- Wipe with a clean, soft cloth.

- Reinstall the wheels and lower the vehicle.

Maintaining a clean brake system prolongs the life of cross drilled rotors.

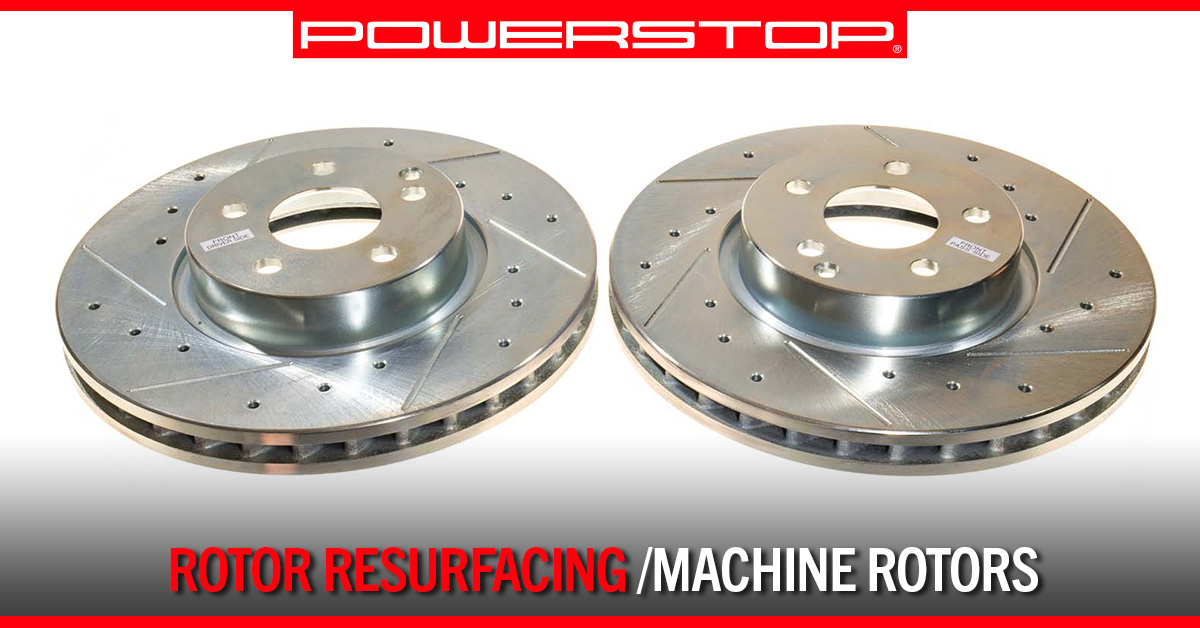

Credit: www.powerstop.com

Conclusion And Final Thoughts

Understanding the capabilities and limitations of cross-drilled rotors is essential. This knowledge can greatly impact the performance and safety of your vehicle.

Summary Of Insights

Cross-drilled rotors are popular for their improved heat dissipation and braking performance. They reduce weight and provide better braking in wet conditions. Despite these advantages, machining cross-drilled rotors can be risky. The process may weaken the rotors, leading to potential failures.

Key Points:

- Improved heat dissipation.

- Better performance in wet conditions.

- Possible weakening from machining.

- Potential for rotor failure.

Future Of Cross Drilled Rotors

The future of cross-drilled rotors looks promising with advancements in materials and technology. New manufacturing techniques may enhance their durability. Innovations in rotor designs aim to reduce the risk of failure. These improvements will likely make cross-drilled rotors more reliable and efficient.

| Aspect | Future Trends |

|---|---|

| Material Advancements | Stronger, more durable materials. |

| Manufacturing Techniques | Enhanced durability and performance. |

| Rotor Designs | Reduced risk of failure. |

As technology evolves, the efficiency of cross-drilled rotors will improve. This evolution will ensure safer and more effective braking systems for vehicles.

Credit: www.reddit.com

Frequently Asked Questions

Can You Machine Cross Drilled Rotors?

Yes, but it’s not recommended. Machining can weaken the structure of cross drilled rotors. It can lead to cracks and reduced performance. Always consult a professional before attempting any modifications.

Why Avoid Machining Cross Drilled Rotors?

Machining cross drilled rotors can compromise their integrity. The process can cause stress points and potential cracking. This affects braking performance and safety.

How To Maintain Cross Drilled Rotors?

Regular inspections and proper cleaning are essential. Avoid using harsh chemicals or abrasive pads. Replace rotors when they show signs of wear or damage.

Are Cross Drilled Rotors Better?

Cross drilled rotors offer improved cooling and performance. They help in heat dissipation during braking. However, they may wear faster than solid rotors.

Conclusion

Machining cross drilled rotors can be tricky. It requires special tools and skills. Some experts advise against it. The structure can weaken. Safety may be at risk. Always consult a professional mechanic. They can provide the best advice. Remember, safety first.

Properly maintained brakes are crucial. Keep them in top condition.