Yes, a compressed air line almost always requires a water-separating filter to protect your tools and ensure clean, dry air. This simple addition prevents moisture damage, improves tool performance, and extends the lifespan of your valuable equipment. It’s a crucial step for anyone using compressed air for DIY projects, auto maintenance, or any task where air quality matters.

Hey there! Samuel H. Murphy here, your friendly guide to all things air compressors. Ever hooked up a tool to your air line and wondered about the quality of the air coming out? Maybe you’ve noticed a bit of sputtering or, worse, a tiny bit of rust on your favorite wrench after a project. It’s a common frustration for many DIYers and homeowners. The good news is, there’s a straightforward solution to a hidden problem: water in your air lines. Let’s dive into why this happens and how a simple filter can save you a lot of headaches and money down the road. We’ll break down exactly what you need to know to keep your tools running smoothly.

Why Water in Your Air Lines is a Big Deal

Think about how air compressors work. They suck in the surrounding air, compress it, and store it in a tank. The air we breathe isn’t perfectly dry; it contains moisture, especially on humid days or in certain climates. When this air gets compressed, the moisture it holds can condense into liquid water. This water then sits in your compressor tank and travels through your air lines.

This might not seem like a huge issue at first, but that little bit of water can cause significant problems:

- Tool Damage: Many air-powered tools, especially delicate ones like paint sprayers or intricate pneumatic tools, are sensitive to moisture. Water can cause internal parts to rust, seize up, or simply not function correctly.

- Corrosion: The inside of your compressor tank and your air lines can also corrode over time due to constant exposure to water. This weakens the metal and can lead to leaks or even tank failure.

- Reduced Performance: Water in the air line can interfere with the smooth operation of your tools, leading to inconsistent pressure, sputtering, or a loss of power.

- Product Contamination: If you’re using compressed air for painting, food processing, or medical applications, water can contaminate your finished product, leading to defects or spoilage.

It’s like trying to drive your car without oil – eventually, things are going to break down! Keeping your compressed air clean and dry is just as important for your tools as regular maintenance is for your car.

What is a Water Separating Filter?

A water-separating filter, often called an air line filter or moisture separator, is a device designed to remove liquid water and other contaminants from compressed air. It typically installs directly onto your air line, often near the compressor outlet or just before your tool.

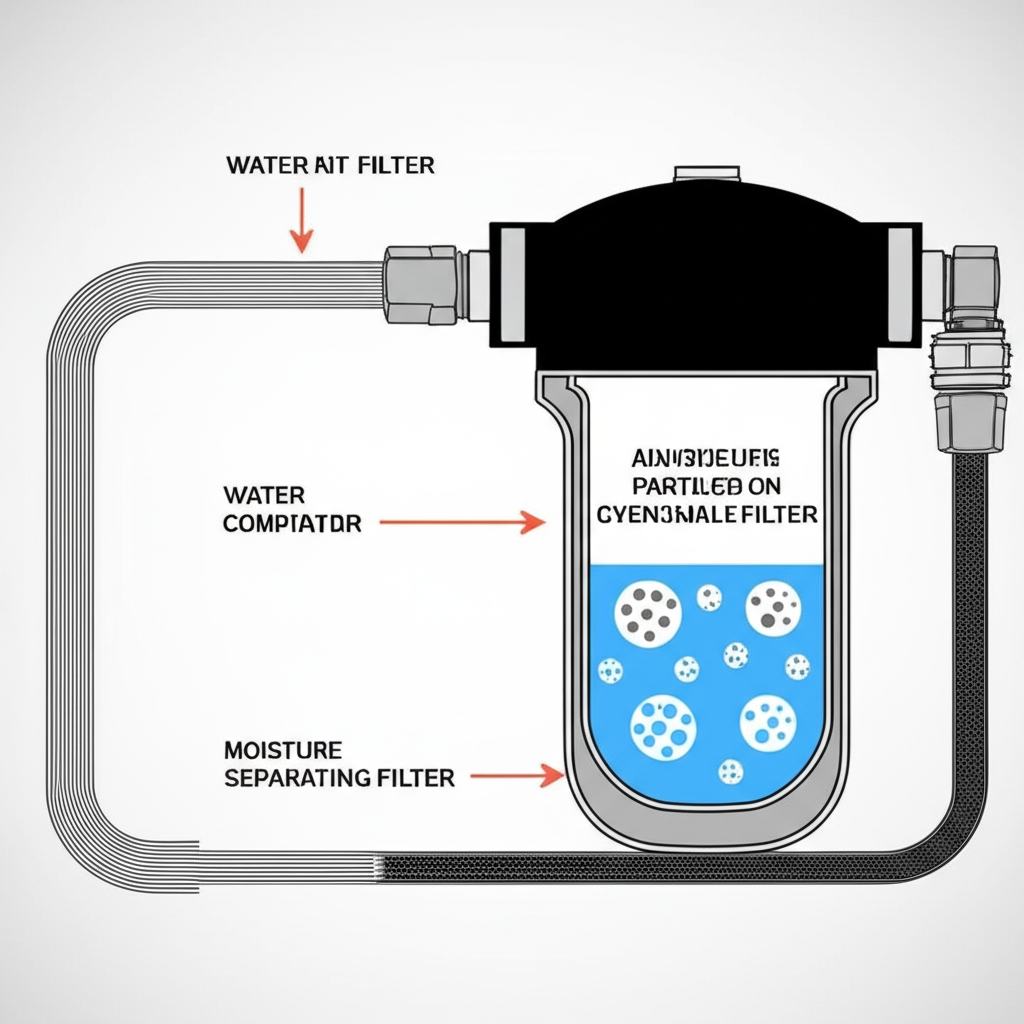

These filters work in a few ways:

- Centrifugal Force: As the compressed air spins through the filter housing, water droplets are flung outwards by centrifugal force and collect at the bottom.

- Coalescing: Tiny water droplets combine (coalesce) into larger ones that are heavy enough to fall out of the airstream.

- Filtration: Many filters also include a porous element that physically traps solid particles like dirt, rust, and oil residue, further cleaning the air.

The collected water is usually drained manually or automatically through a small valve or petcock at the bottom of the filter. Think of it as a tiny, specialized strainer for your air.

Does a Compressed Air Line Require a Water Separating Filter?

Let’s get straight to the point: Yes, for most applications, a compressed air line absolutely requires a water-separating filter. While some very basic, low-demand uses might tolerate a bit of moisture, the vast majority of homeowner and DIY tasks benefit immensely from clean, dry air. It’s not just about protecting expensive tools; it’s about ensuring your work turns out right the first time.

Consider these common uses:

- Inflating Tires: While a little moisture won’t hurt your tires, clean air is always better.

- Running Nail Guns: Moisture can cause rust inside the nail gun, leading to jams and reduced lifespan.

- Using Paint Sprayers: Water in the air line is a primary cause of “fisheyes” and other surface defects in paint jobs.

- Winterizing Irrigation Systems: You need dry air to effectively blow out water, preventing freeze damage.

- Operating Delicate Tools: Air-powered sanders, impact wrenches, and air ratchets are all susceptible to moisture-related damage.

The only time you might potentially get away without one is for extremely short, infrequent bursts of air for very simple tasks, like blowing dust off a workbench. But even then, why risk it? The cost of a good filter is minimal compared to the cost of repairing or replacing a damaged tool.

Types of Air Line Filters

Not all filters are created equal. Here’s a quick look at the common types you’ll encounter:

| Filter Type | Primary Function | Best For | Considerations |

|---|---|---|---|

| Water Separator (In-line) | Removes liquid water and larger particles. | General use, protecting tools from moisture. | Requires manual or automatic draining. |

| Coalescing Filter | Removes very fine water droplets, oil aerosols, and small particles. | High-quality finish work (painting), sensitive tools. | Often used in conjunction with a water separator. |

| Particulate Filter | Removes solid dust, rust, and debris. | Protecting tools from physical contaminants. | Doesn’t remove moisture effectively on its own. |

| Desiccant Dryer | Removes moisture vapor by adsorption. | Applications requiring extremely dry air (e.g., electronics, medical). | More complex, requires maintenance/replacement of desiccant. |

For most homeowners and DIYers, a good quality in-line water separator is the essential first step. If you’re getting into more advanced tasks like professional painting or working with very sensitive electronics, you might consider adding a coalescing filter downstream.

How to Install a Water Separating Filter

Installing a water-separating filter is usually a straightforward process that most people can handle with basic tools. It’s a great DIY project that pays dividends in tool longevity.

Tools You Might Need:

- Adjustable wrench or pipe wrench

- Pipe thread sealant tape (Teflon tape)

- The water-separating filter itself

- Safety glasses

Step-by-Step Installation:

- Safety First: Ensure your air compressor is turned OFF and the tank pressure is completely released. Never work on an air system under pressure. Wear your safety glasses.

- Locate the Outlet: Identify the main air outlet port on your compressor tank or the end of your primary air hose, depending on where you want to install the filter.

- Prepare the Threads: Clean the threads on the compressor outlet or hose fitting. Apply a few wraps of pipe thread sealant tape (Teflon tape) clockwise around the threads. This helps create a tight seal and prevent leaks.

- Install the Filter: Carefully thread the filter onto the outlet port. Hand-tighten it first to ensure it’s properly seated and not cross-threaded.

- Tighten with Wrench: Use an adjustable wrench or pipe wrench to gently tighten the filter. Tighten it firmly, but avoid over-tightening, which can damage the threads or the filter housing. The goal is a snug fit that prevents leaks. Check the filter manufacturer’s instructions for specific torque recommendations if available.

- Connect Air Hose: Attach your main air hose to the outlet port on the filter. Ensure this connection is also secure and leak-free.

- Test for Leaks: Turn on your air compressor and allow it to build pressure. Listen carefully for any hissing sounds around the filter and hose connections, which would indicate a leak. If you find a leak, turn off the compressor, release the pressure, and re-tighten the connection or reapply Teflon tape.

- Drain Regularly: Once installed, remember to drain the collected water from the filter bowl regularly. Check it after each use, especially in humid conditions.

It’s a good idea to install filters at multiple points in your system if you have long hose runs or multiple work areas. A filter at the compressor outlet is essential, and placing another one near the tool you’re using can provide an extra layer of protection.

Maintaining Your Water Separating Filter

Your water-separating filter is a simple device, but it still requires a little care to keep it working effectively. The most important maintenance task is regular draining.

Draining the Filter

Most filters have a small valve or petcock at the bottom of the collection bowl. To drain:

- Ensure the compressor is turned OFF and depressurized.

- Place a small container or rag under the drain valve.

- Slowly open the valve. You’ll see water and possibly some air escape.

- Close the valve once all the water has drained.

Some filters have automatic drains that open when pressure drops below a certain level, but it’s still a good habit to check them manually.

Cleaning and Replacing Filter Elements

Over time, the filter element inside can become clogged with dirt and debris. The frequency of replacement depends on how much you use your compressor and the quality of the air you’re drawing in. Check the manufacturer’s recommendations, but generally, inspect the element annually or if you notice reduced airflow.

To clean or replace the element:

- Turn off and depressurize the compressor.

- Carefully unscrew the filter bowl (the transparent or metal cup at the bottom).

- Remove the filter element inside.

- If it’s a reusable element, you might be able to rinse it with water or a mild cleaning solution (check manufacturer instructions). Let it dry completely before reinstallation.

- If the element is disposable or heavily contaminated, replace it with a new one compatible with your filter model.

- Reassemble the filter bowl, ensuring the seal is properly seated.

- Tighten the bowl firmly but don’t overtighten.

- Restore pressure and check for leaks.

A clean, well-maintained filter ensures optimal airflow and maximum protection for your tools.

When Else Might You Need Advanced Filtration?

While a water-separating filter is the essential starting point, some specific applications demand even cleaner air. If your work involves:

- High-Quality Painting: Achieving a flawless finish requires air free not only from water but also from oil mist and fine particles. A coalescing filter, often installed downstream of a water separator, is crucial here. It uses a special media to trap even microscopic contaminants.

- Food or Beverage Industry: Compressed air used in food processing must meet stringent purity standards to prevent contamination. This often involves multi-stage filtration systems, including oil removal filters and activated carbon filters.

- Medical Applications: Similarly, medical equipment powered by compressed air needs exceptionally clean and dry air to ensure patient safety.

- Electronics Manufacturing: Sensitive electronic components can be damaged by moisture or contaminants in the air supply.

For these specialized needs, you might look into filter-regulator-lubricator (FRL) units or more complex compressed air treatment systems. However, for the typical homeowner or DIYer, a good water separator is the most critical component.

According to the Occupational Safety and Health Administration (OSHA), maintaining compressed air systems properly is key to preventing accidents and ensuring efficient operation. While OSHA’s guidelines often focus on safety hazards like high-pressure air, the principle of maintaining system integrity extends to protecting your equipment from internal issues like moisture.

Frequently Asked Questions (FAQ)

Do I need a water separator if I live in a dry climate?

Even in dry climates, air contains some moisture. Compression still causes this moisture to condense. While you might collect less water than in a humid area, a filter still provides essential protection against rust and particle buildup in your tools.

Can I just drain my compressor tank instead of using a filter?

Draining your compressor tank regularly is crucial for removing accumulated water. However, it doesn’t prevent water from traveling through the air lines after it leaves the tank. A filter actively removes moisture from the air stream as it flows, offering continuous protection for your tools.

Where is the best place to install a water separator filter?

The most common and effective location is on the main air outlet from your compressor tank, right before your primary air hose. If you have very long hoses or multiple tools that require high air quality, you might also install filters closer to the tools themselves.

How often should I drain the water from the filter?

It’s best practice to drain the filter after every use, especially if you’re working in humid conditions. Even if you don’t see much water, draining it regularly prevents buildup and potential corrosion within the filter bowl itself.

What happens if I don’t use a water separator filter?

Without a filter, moisture and debris from your compressor tank can travel through your air lines and into your tools. This can cause internal rusting, tool malfunction, reduced performance, and a significantly shortened tool lifespan. For tasks like painting, it can ruin your finish.

Are all air filters the same?

No, there are different types of air filters designed for different purposes. Water separators primarily remove liquid water, while coalescing filters remove finer mists and oil, and particulate filters remove solid debris. For most DIYers, a water separator is the essential first line of defense.

Conclusion

So, does a compressed air line require a water-separating filter? The answer is a resounding yes for anyone who wants to protect their investment in air tools and achieve the best possible results from their projects. It’s a simple, affordable addition that acts as a crucial guardian for your equipment.

By understanding how moisture gets into your air system and how a filter works to remove it, you’re taking a significant step towards smarter tool usage and maintenance. From keeping your nail gun firing smoothly to ensuring a perfect paint job, clean and dry air makes all the difference. Remember to install it correctly, drain it regularly, and replace the filter element as needed. Your tools will thank you for it with years of reliable performance.

Happy building, fixing, and creating!