Air compressor unloader valves prevent tank over-pressurization and motor strain by venting compressed air when the compressor stops. Understanding how it works ensures safe operation and longevity for your equipment.

Have you ever wondered what that little valve on your air compressor does? It’s a crucial part, and understanding it can save you headaches and money. Many folks find air compressor maintenance a bit mysterious, especially when things aren’t working quite right. You might hear strange noises or notice your compressor cycling oddly. Don’t worry! We’re going to break down exactly how your air compressor unloader valve works in a way that’s easy to grasp. We’ll guide you through its function, why it’s so important, and what to do if you suspect a problem. Get ready to demystify this essential component!

What Exactly is an Air Compressor Unloader Valve?

Think of your air compressor like a team player. It works hard to build up air pressure in a tank. But when it’s done, it needs a way to rest without causing problems. That’s where the unloader valve steps in. It’s a safety device, and it’s also a smart energy saver.

Essentially, the unloader valve is a small, often brass or aluminum, component connected to the compressor’s pump and the air tank. Its main job is to release the air pressure that’s trapped in the pump head and the discharge line after the compressor motor shuts off. This might sound simple, but it’s a really clever piece of engineering.

Why is this so important? Well, when a compressor stops, there’s still a lot of compressed air sitting in the pump’s cylinder and the pipe leading to the tank. If this air were to stay there, it would create immense back pressure. This back pressure would make it incredibly difficult for the motor to start up again the next time it’s needed. It’s like trying to push a heavy door closed when someone is already pushing it open from the other side – it takes a lot more effort!

This extra effort puts a huge strain on the motor, its electrical components (like capacitors and switches), and even the pump itself. Over time, this can lead to premature wear and tear, or even outright failure. The unloader valve, by venting this trapped air, makes sure the compressor can start up smoothly and easily, every single time. It’s a silent guardian of your air compressor’s health.

The “Why” Behind the Unloader Valve: More Than Just a Vent

You might be thinking, “Okay, it vents air, but why is that so crucial?” It boils down to two main reasons: preventing damage and saving energy.

Preventing Motor Strain and Damage

As we touched on, the biggest benefit of the unloader valve is protecting your compressor’s motor. When the compressor shuts off, the unloader valve opens, releasing the air trapped in the pump head and discharge line. This action significantly reduces the pressure the motor has to overcome when it restarts.

Imagine trying to start a car with the parking brake fully engaged. It’s tough, right? Without an unloader valve, starting an air compressor would be similar. The motor would have to fight against the residual pressure in the pump. This constant struggle can cause:

Overheating: Motors working harder than they should will generate more heat.

Electrical Component Failure: Start capacitors, run capacitors, and thermal overload switches can be damaged by the excessive current drawn during difficult startups.

Mechanical Wear: The extra force needed to turn the motor and pump can accelerate wear on bearings, pistons, and connecting rods.

The unloader valve effectively “unloads” the motor, allowing it to spin freely when it restarts, just like releasing the parking brake on a car.

Energy Efficiency and Longevity

While not its primary function, the unloader valve indirectly contributes to energy efficiency and the overall longevity of your compressor. By allowing for easier starts, it reduces the electrical surge that occurs when a motor struggles to begin. This means less wasted electricity over time.

More importantly, by preventing the strain that leads to component damage, the unloader valve helps your compressor last longer. A well-functioning unloader valve means fewer repairs and a more reliable tool for your projects.

How Does an Air Compressor Unloader Valve Actually Work?

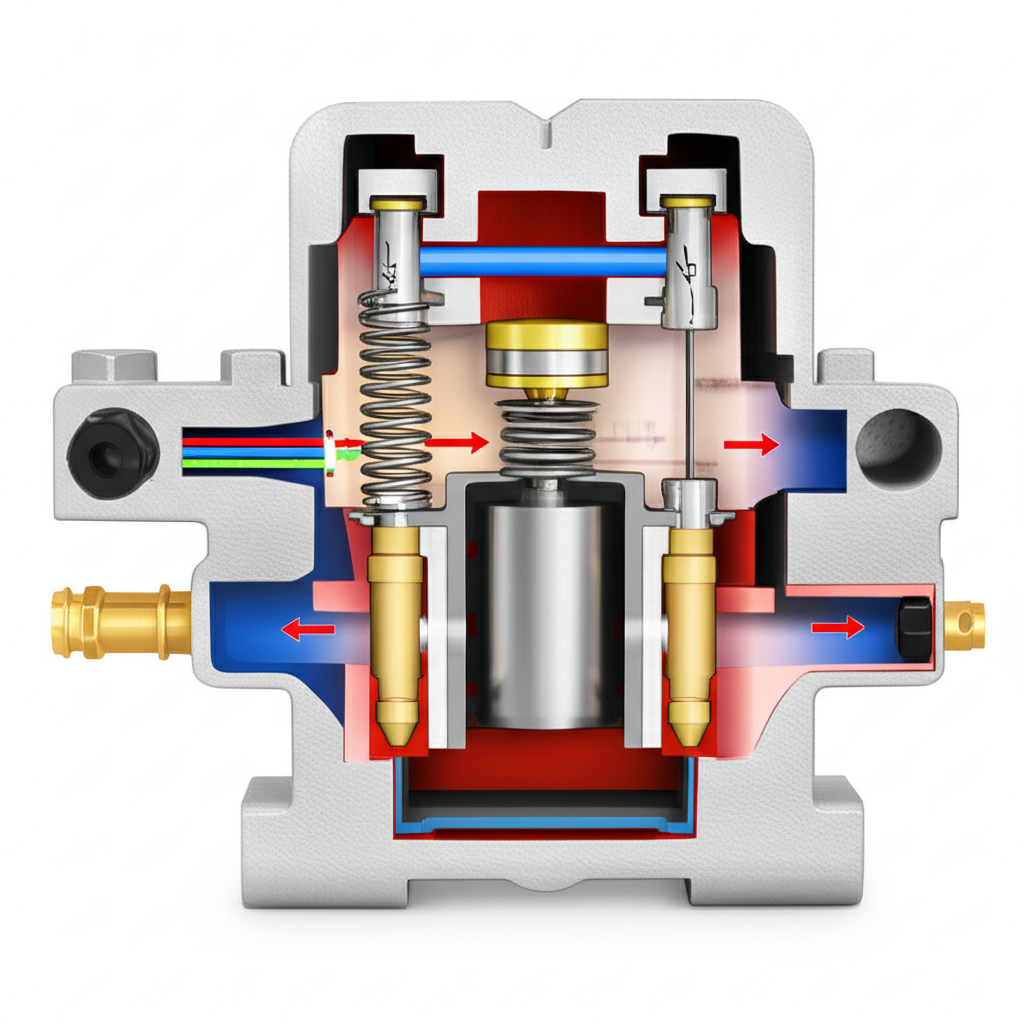

The magic of the unloader valve lies in its simple yet effective design, which relies on pressure differentials and a spring-loaded mechanism. While there are a few variations, the most common types are either directly attached to the pump head or controlled by a solenoid valve.

Let’s break down the general process:

1. Compressor Running: As the compressor pump compresses air, it pushes it into the tank. The pressure in the tank rises.

2. Pressure Switch Activation: A pressure switch, typically mounted near the tank, monitors the air pressure. When the pressure reaches the upper limit set by the user (e.g., 120 PSI), the pressure switch signals the motor to shut off.

3. Unloader Valve Engagement (The Crucial Step): This is where the unloader valve comes into play. There are a couple of common ways this happens:

Mechanical Unloader Valve (Most Common on Smaller Compressors): These valves are usually connected to the discharge line between the pump and the tank. When the motor stops, the pressure in the tank pushes back on a diaphragm or piston within the unloader valve. This force overcomes a spring, opening a vent port. This vent port is typically connected to a small tube that goes back up to the pump head, or it might simply vent to the atmosphere. The air trapped in the pump head and discharge line is released through this vent.

Solenoid Unloader Valve (Common on Larger or More Advanced Compressors): In this setup, a solenoid valve is used to control the venting. When the pressure switch shuts off the motor, it also sends a signal to the solenoid. The solenoid then opens a small port, allowing air from the tank to flow to the unloader valve mechanism, which then opens the main vent to release the trapped air from the pump.

4. Pressure Release: The air trapped in the pump cylinder and the discharge line is vented out. This reduces the pressure in the pump head to near atmospheric levels.

5. Compressor Ready to Restart: With the pressure relieved, the motor can now start up easily the next time the pressure switch calls for it.

Key Components of a Typical Unloader Valve

While designs vary, most unloader valves share these fundamental parts:

Valve Body: The main housing, usually made of brass or aluminum.

Diaphragm or Piston: A movable component that is acted upon by pressure.

Spring: Provides a counter-force to keep the valve closed under normal operating pressure.

Vent Port: The opening through which the trapped air is released.

Inlet Port: Connects to the discharge line from the pump.

Outlet Port (or connection to vent tube): Where the air exits.

Here’s a simplified look at how pressure affects the valve:

| Condition | Pressure in Discharge Line | Unloader Valve State | Action |

| :————– | :————————- | :——————- | :—————————————- |

| Compressor On | High | Closed | Air flows to tank. |

| Compressor Off | High (trapped) | Opens | Vents trapped air from pump head/line. |

| Compressor Off | Low (vented) | Remains Open | Until pressure builds again or manually reset. |

Types of Unloader Valves and How They Differ

The basic principle of venting trapped air remains the same, but the implementation can differ. Understanding these differences can help you identify what you have and how it operates.

1. Mechanical Unloader Valves

These are the most common on smaller, portable air compressors. They are typically integrated directly into the pump head or discharge manifold.

How they work: They rely on the pressure differential between the tank and the pump discharge line. When the compressor stops, the stored pressure in the tank (or a small pilot line) acts on a diaphragm or piston, forcing it to open a vent. This vent releases the air trapped in the pump cylinder.

Pros: Simple, reliable, and require no electrical connections.

Cons: Can sometimes stick open or closed if they get dirty or corroded. The venting might be less precise than solenoid types.

2. Solenoid Unloader Valves

Found on larger, stationary, or more advanced industrial compressors, these use an electrical signal to control the venting.

How they work: A solenoid (an electromagnetically operated valve) is wired into the compressor’s control system. When the pressure switch tells the motor to stop, it also sends a signal to the solenoid. The solenoid opens a small port, allowing tank pressure to act on the main unloader valve, which then vents the pump discharge.

Pros: More precise control, can be integrated into more complex control systems, and often provide a cleaner, more immediate vent.

Cons: More complex, requires electrical connections, and adds another potential point of failure (the solenoid itself or its wiring).

3. Pressure-Actuated Check Valve Unloaders

Some designs combine the check valve (which prevents air from flowing back from the tank to the pump) with the unloader function.

How they work: The check valve is designed to open slightly when the pressure drops in the discharge line after the motor stops, allowing the trapped air to escape.

Pros: Compact design, fewer parts.

Cons: Can be more prone to leaks if the check valve seal isn’t perfect.

Troubleshooting Common Unloader Valve Issues

A faulty unloader valve can lead to several problems, most of which revolve around the compressor’s ability to start or maintain pressure. Here are some common symptoms and what they might mean:

Symptom: Compressor Motor Hums but Doesn’t Start, or Trips the Breaker

Possible Cause: The unloader valve is not venting properly, leaving pressure in the pump head. The motor is struggling to overcome this back pressure.

What to check:

Is the unloader valve stuck closed?

Is the vent port blocked?

If it’s a solenoid type, is the solenoid receiving power and opening?

Symptom: Air Leaks from the Unloader Valve Vent When the Compressor is Running

Possible Cause: The unloader valve is not sealing properly when the compressor is operating. This means air is escaping from the pump head or discharge line back into the vent.

What to check:

Is there debris on the valve seat or diaphragm?

Is the spring weakened or broken?

Is the diaphragm or piston damaged?

Symptom: Compressor Cycles Too Frequently or Doesn’t Reach Full Pressure

Possible Cause: While less common for the unloader valve itself to cause under-pressure issues, a partially stuck-open unloader could lead to a slow loss of pressure. More often, this points to other issues like leaks elsewhere in the system or a worn pump.

What to check:

Ensure the unloader valve is fully closing when the compressor is running.

Symptom: Loud “Hiss” or “Puff” Sound When Compressor Shuts Off

This is normal! This sound indicates the unloader valve is doing its job, venting the trapped air. You should hear this sound every time the compressor stops.

How to Maintain Your Unloader Valve

Proper maintenance is key to ensuring your unloader valve works reliably for years to come. Fortunately, it’s not overly complicated.

Regular Inspection

Listen: Pay attention to the sounds your compressor makes. The characteristic “hiss” when it shuts off is a good sign it’s working.

Visual Check: Periodically look at the unloader valve. Ensure there are no obvious signs of damage, corrosion, or leaks when the compressor is running.

Cleaning

When to Clean: If you suspect issues or during routine maintenance (e.g., annually or every 500 hours of operation, depending on your compressor’s manual), you might consider cleaning the unloader valve.

How to Clean:

1. Safety First: ALWAYS disconnect the power to the compressor and ensure the tank is completely drained of air before attempting any maintenance.

2. Access the Valve: Depending on your compressor, you might need to remove a cover or disconnect a line to access the unloader valve.

3. Disassembly (Carefully!): If you’re comfortable, you can carefully disassemble the valve. Note the order of parts. A common method involves unscrewing the valve body.

4. Clean Components: Use a mild solvent (like carburetor cleaner or even soapy water) and a soft brush or cloth to clean the valve body, diaphragm, spring, and any seals. Ensure all ports are clear.

5. Inspect for Damage: Look for any cracks, tears in the diaphragm, or worn seals. If any parts are damaged, they will need to be replaced.

6. Reassembly: Carefully reassemble the valve in the reverse order of disassembly. Ensure all connections are snug but not overtightened.

7. Test: Reconnect power and run the compressor to test. Listen for the characteristic venting sound when it shuts off.

Replacement

When to Replace: If cleaning doesn’t resolve issues, or if you find damaged components during inspection, it’s time for a replacement.

Finding the Right Part: Unloader valves are specific to compressor models. You’ll need to identify your compressor’s make and model number to order the correct replacement part. Consult your owner’s manual or the manufacturer’s website.

Installation: The process is similar to disassembly and cleaning. Ensure you follow safety procedures and have the correct replacement part.

Important Note on Maintenance

Always refer to your air compressor’s owner’s manual for specific maintenance procedures and recommendations. Some manufacturers advise against disassembling the unloader valve, suggesting replacement as the primary solution for issues. For homeowners and DIYers, it’s often safer and more practical to replace a malfunctioning valve rather than attempt a complex repair, especially if you’re not mechanically inclined.

Understanding Different Unloader Valve Configurations

The way the unloader valve is integrated into the compressor system can vary, impacting how it’s controlled and maintained.

Integrated Pump Head Valves

Many smaller compressors have the unloader valve built directly into the pump head assembly.

How it looks: You won’t see a separate external valve. Instead, the venting mechanism is part of the cylinder head or discharge manifold. A small tube often runs from this area back up to the cylinder head.

Maintenance: Cleaning might involve accessing this area, but often, if these fail, the entire pump head assembly might need replacement, or a small external unloader kit might be adapted.

External Valve Body with Pilot Line

This is a common setup where a distinct valve body is mounted on the discharge line.

How it looks: A separate valve unit, often brass, with an inlet from the pump, an outlet to the tank, and a small “pilot” line that connects back to the pump head or a pressure switch.

Maintenance: This type is usually the easiest to access for cleaning or replacement.

Solenoid-Controlled Systems

As mentioned, these use an electrical solenoid to activate the venting mechanism.

How it looks: You’ll see a typical unloader valve (often a diaphragm-style) connected to a solenoid coil. This solenoid is wired into the compressor’s electrical circuit.

Maintenance: Requires checking electrical connections and the solenoid’s function in addition to the mechanical aspects of the unloader valve itself.

Table: Common Unloader Valve Configurations

| Configuration Type | Typical Location | Control Mechanism | Maintenance Ease | Common On |

| :—————————– | :———————- | :———————– | :————— | :————– |

| Integrated Pump Head | Within pump head | Mechanical (internal) | Low | Small portable |

| External Valve Body | Discharge line | Mechanical (pilot line) | High | Many portable |

| Solenoid Controlled | Discharge line/manifold | Electrical (solenoid) | Medium | Larger/Industrial |

| Pressure-Actuated Check Valve | Check valve assembly | Mechanical (pressure) | Medium | Some models |

When to Call a Professional

While many unloader valve issues can be tackled by a diligent DIYer, there are times when it’s best to seek professional help.

Complex Systems: If you have a large, industrial-grade compressor with intricate electrical controls and multiple stages, it’s wise to call a qualified technician.

Uncertainty: If you’re unsure about any step in the maintenance or replacement process, or if you can’t identify the source of the problem, don’t risk damaging your equipment further.

Persistent Issues: If you’ve performed basic maintenance and the problem persists, a professional will have the diagnostic tools and expertise to pinpoint the exact cause.

* Safety Concerns: If you’re uncomfortable working with compressed air systems or electrical components, always err on the side of caution and call an expert.

Frequently Asked Questions About Air Compressor Unloader Valves

Q1: What is the main purpose of an air compressor unloader valve?

The main purpose is to vent compressed air from the pump head and discharge line when the compressor motor shuts off. This prevents back pressure, making it easier for the motor to restart and reducing strain on its components.

Q2: How do I know if my unloader valve is working correctly?

You should hear a distinct “hiss” or “puff” sound for a few seconds when your compressor motor shuts off. This sound indicates the valve is venting the trapped air.

Q3: Can I operate my air compressor without an unloader valve?

No, it is not recommended. Operating without a functioning unloader valve will put excessive strain on the motor, leading to overheating, premature wear, and potential electrical or mechanical failure.

Q4: What causes an unloader valve to fail?

Common causes include