The cost to replace an air conditioner compressor typically ranges from $1,000 to $3,500, with the average falling around $2,200. This includes the compressor itself, labor, and associated parts. Factors like the type of AC system, brand, your location, and the complexity of the installation significantly influence the final price.

It’s that sinking feeling when your air conditioner starts making strange noises or, worse, stops cooling altogether. For many homeowners, the biggest worry isn’t just being uncomfortable, but the potential cost of repairs. And when the conversation turns to a failing AC compressor, the question that immediately pops into mind is: “How much is an air conditioner compressor to replace?” It’s a big question, and the answer can feel a bit overwhelming at first. But don’t worry, we’re going to break it down together. Think of me as your friendly guide, here to demystify the process and help you understand the factors that go into this essential repair.

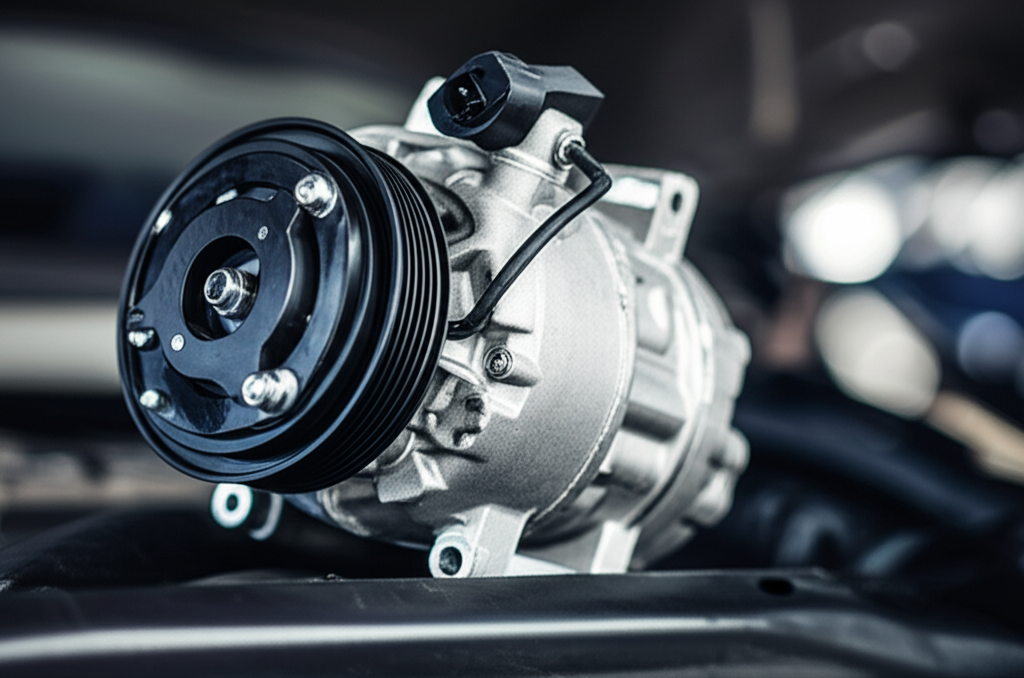

Understanding Your AC Compressor: The Heart of Your System

Before we dive into the costs, let’s chat briefly about what this vital part actually does. Your air conditioner’s compressor is like the heart of your cooling system. It’s responsible for pumping the refrigerant through the coils, which is how your home actually gets cooled. When this component fails, your entire AC system grinds to a halt.

How Much is an Air Conditioner Compressor to Replace? The Big Picture

So, you’re probably wondering about the bottom line. When it comes to replacing an AC compressor, the cost is a significant investment. Generally, you can expect the total price to fall somewhere between $1,000 and $3,500. This broad range accounts for many variables, but it gives you a good starting point for budgeting. The average cost often lands around $2,200.

This price covers several components:

The Compressor Unit: This is the main part, and its price varies widely.

Labor: A qualified HVAC technician’s time is crucial for proper installation.

Additional Parts: Refrigerant, electrical components, and other small parts are often needed.

Service Call Fees: Some companies have a base fee just for coming to your home.

Factors Influencing AC Compressor Replacement Cost

Now, let’s explore what makes that price tag go up or down. Understanding these factors can help you anticipate potential costs and make informed decisions.

1. Type of AC System

The type of air conditioning system you have plays a big role.

Central Air Conditioners: These are the most common systems in homes. Replacing a compressor in a central AC unit is what most people are referring to when they ask about AC compressor costs.

Ductless Mini-Split Systems: These systems have smaller, individual compressors for each indoor unit. While the individual compressors might be less expensive, if multiple units are affected or if it’s a larger system, the cost can still add up.

Heat Pumps: Heat pumps work in reverse during the winter to provide heat. This dual function can sometimes make their compressors slightly more complex and, therefore, more expensive to replace.

2. Brand and Model of the Compressor

Just like cars or appliances, AC compressors come in different brands and models, each with its own price point.

Premium Brands: Brands known for high-quality and reliability might offer compressors that are more expensive upfront but could potentially last longer.

Standard Brands: More budget-friendly options are available, but it’s always wise to balance cost with expected performance and lifespan.

Specific Unit Requirements: The exact model of your existing AC unit will dictate the specific compressor needed. Some older or less common models might have harder-to-find parts, which can increase costs.

3. Labor Costs and Location

The technician’s hourly rate and the general cost of living in your area significantly impact the total price.

Geographic Location: Major metropolitan areas typically have higher labor rates than rural areas.

HVAC Company: Different companies have different pricing structures. It’s often a good idea to get quotes from a few different reputable HVAC contractors.

Technician Expertise: Highly experienced and certified technicians might command higher rates, but their expertise can ensure a job done right.

4. Complexity of Installation

Sometimes, replacing a compressor isn’t a straightforward swap.

Accessibility: If the outdoor unit is in a difficult-to-reach location (e.g., on a steep roof or in a tight space), it can increase labor time and cost.

System Type: Some AC systems are more complex to work with than others. For instance, older R-22 refrigerant systems might require special handling and recovery procedures, adding to the cost. For more on refrigerants, you can check out resources from the U.S. Environmental Protection Agency (EPA) on refrigerants and their impact.

Additional Repairs: If the technician discovers other issues while working on the compressor, such as problems with the capacitor, contactor, or refrigerant lines, these will add to the overall bill.

5. Emergency Service Fees

If your AC breaks down during a heatwave or on a holiday, you might need emergency service. Most HVAC companies charge a premium for after-hours, weekend, or holiday service calls.

Understanding Compressor Types and Their Cost Implications

There are a few common types of compressors used in residential AC systems, and each has different characteristics that can affect the replacement cost.

| Compressor Type | Description | Typical Cost (Part Only) | Considerations |

| :—————- | :———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————– | :———————– | :————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————— |

| Reciprocating | Also known as a piston compressor, this type uses a piston and cylinder mechanism to compress refrigerant. It’s a more traditional design, often found in older systems. | $500 – $1,200 | Can be noisy and less energy-efficient than newer types. Replacement parts might be readily available for older units, but the compressor itself might be less common in new installations. |

| Rotary | These compressors use rotating parts to compress refrigerant. There are two main sub-types: rolling piston and rotary vane. They are generally quieter and more efficient than reciprocating compressors. | $600 – $1,500 | Offers smoother operation and better energy efficiency. Can be a good upgrade if replacing an older reciprocating unit, though the system might need to be compatible. |

| Scroll | This is the most common type in modern residential AC systems. It uses two interleaved spiral-shaped scrolls to compress the refrigerant. They are known for their high efficiency, reliability, and quiet operation. | $800 – $2,000+ | Offers superior efficiency and durability. Often the most expensive upfront but can lead to energy savings over time. Most HVAC technicians are very familiar with installing and servicing scroll compressors. |

| Inverter | These are a type of scroll compressor that can vary their speed. This allows them to precisely control the cooling output, leading to significant energy savings and more consistent temperatures. | $1,000 – $2,500+ | The most energy-efficient option, leading to lower utility bills. The variable speed technology can also lead to quieter operation. However, they are typically the most expensive to purchase and may require specialized diagnostic tools for repair.