Choosing the right hacksaw blade for metal is key to clean, fast, and safe cuts. Look for TPI (Teeth Per Inch) matching your metal type: higher TPI for thinner metals and lower TPI for thicker metals. This guide breaks down blade selection and usage for perfect metal cuts every time.

Cutting metal can feel a bit daunting, right? Maybe you’ve tried it before, and the blade skipped, the cut was jagged, or it just felt like you were wrestling a bear. It’s a common frustration, but the good news is that the right hacksaw blade makes a world of difference. Think of it like using the right tool for the job – a hammer for nails, a screwdriver for screws. For metal, the blade is your secret weapon. We’re going to walk through exactly how to pick the perfect hacksaw blade for your metal project and how to use it like a pro. Get ready to make those metal cuts smooth and easy!

Understanding Your Hacksaw Blade: The Tooth Tells the Tale

The heart of any successful metal cut with a hacksaw lies in its blade. It might look simple, but a lot of engineering goes into these thin strips of metal. The most crucial feature you’ll notice is the teeth. These aren’t just any teeth; they’re designed with a specific purpose for cutting metal efficiently and safely. Let’s break down what makes a hacksaw blade tick.

Teeth Per Inch (TPI): Your Cutting Compass

The most important number you’ll see on a hacksaw blade is its TPI, or Teeth Per Inch. This tells you how many teeth are packed into every inch of the blade. It’s like the grit on sandpaper – the higher the number, the finer the cut. But for metal, it’s more about matching the TPI to the thickness of the material you’re cutting.

- Why TPI Matters: If you use a blade with too few teeth on thin metal, the teeth can dig in too aggressively, snag, and break. If you use a blade with too many teeth on thick metal, the fine teeth can get clogged with metal shavings, leading to slow, inefficient cutting and premature blade wear.

Common TPI Ranges and Their Uses

Here’s a simple guide to help you choose the right TPI for different metal thicknesses:

| TPI Range | Ideal For | Characteristics |

|---|---|---|

| 14 TPI | Thick, soft metals (e.g., pipe, rebar, thick steel stock) | Coarse teeth for fast material removal on tough jobs. |

| 18 TPI | Medium thickness metals (e.g., angle iron, conduit, medium steel bars) | A good all-around choice for general metal cutting. |

| 24 TPI | Thinner metals (e.g., sheet metal, thin-walled tubing, conduit) | Provides a smoother finish on thinner materials. |

| 32 TPI | Very thin metals (e.g., thin sheet metal, small diameter rods) | Fine teeth for precision cuts on delicate materials, minimizes snagging. |

Blade Material: Durability and Performance

Not all hacksaw blades are created equal when it comes to the material they’re made from. The material impacts how long the blade lasts and how well it cuts different types of metal.

- High-Speed Steel (HSS): These blades are hardened and can withstand higher temperatures generated during cutting. They are excellent for cutting harder metals and offer longer blade life.

- Bi-Metal Blades: These are the workhorses of the hacksaw world. They combine a flexible spring steel back with HSS teeth. This means they are tough, durable, and less likely to shatter than all-HSS blades. Bi-metal blades are highly recommended for most DIY metal cutting tasks because of their versatility and resistance to breakage.

- Carbon Steel Blades: These are the most basic and least expensive. They are best suited for softer metals and less demanding tasks. They tend to wear out faster and can be more prone to breaking if pushed too hard.

Blade Length and Thickness

While TPI is king, blade length and thickness also play a role. Most standard hacksaws use 10-inch or 12-inch blades. The length of the blade affects the length of the stroke you can achieve, which can influence cutting speed. The thickness of the blade (often referred to as the blade’s “set” or “kerf”) influences its rigidity and the width of the cut. Thicker blades are generally more rigid but may require more effort to cut.

Choosing the Right Blade: A Step-by-Step Approach

Now that you know the basics, let’s put it into practice. Selecting the correct blade is straightforward once you know what to look for.

- Identify the Metal: What are you cutting? Is it thick steel pipe, thin aluminum sheet, or copper tubing?

- Determine Metal Thickness: Is it thin, medium, or thick? This is the most critical factor for TPI selection.

- Consult the TPI Guide: Use the table above to match the metal thickness to the appropriate TPI. Remember:

- Thin metal = High TPI (24-32)

- Medium metal = Medium TPI (18-24)

- Thick metal = Low TPI (14-18)

- Consider Blade Material: For most DIYers and general metal cutting, a bi-metal blade is your best bet. It offers a great balance of durability, flexibility, and cutting performance.

- Check the Teeth Engagement Rule: A good rule of thumb is to ensure that at least two, and ideally three, teeth are in contact with the metal at all times. This prevents the teeth from snagging and breaking.

Example Scenarios:

- Cutting a 1/2-inch steel rod: This is medium to thick metal. A 18 TPI bi-metal blade would be a great choice.

- Cutting thin aluminum flashing: This is very thin metal. A 32 TPI bi-metal blade will give you a clean, smooth cut without snagging.

- Cutting electrical conduit (EMT): This is typically thin-walled steel tubing. A 24 TPI bi-metal blade is usually perfect for this.

Getting Your Hacksaw Ready: Blade Installation and Tensioning

Once you’ve picked the perfect blade, it’s time to get your hacksaw ready. Proper installation and tensioning are crucial for safety and cutting efficiency. A loose blade can bend, break, or cause an unsafe cutting experience.

Installing the Blade

Hacksaw blades have holes at each end that fit onto pins or hooks on the hacksaw frame. The teeth of the blade should always face away from the handle – in the direction of the cutting stroke.

- Loosen the Tension Knob: Most hacksaws have a tensioning knob or wing nut at the end of the frame. Turn this counter-clockwise to loosen the blade tension.

- Insert the Blade: Place one end of the blade into the hook or slot at the front of the hacksaw frame. Then, bend the frame slightly to bring the other end of the blade up to the hook or slot at the back of the frame.

- Ensure Correct Tooth Direction: Double-check that the teeth are pointing away from the handle.

- Tension the Blade: Gradually tighten the tension knob by turning it clockwise. You want the blade to be taut, like a guitar string.

Tensioning the Blade: The Right Amount of Tightness

This is where many beginners go wrong. Too loose, and the blade will wander, flex, and potentially break. Too tight, and you risk snapping the blade or damaging the frame.

- The “Ping” Test: A common method is to pluck the blade gently with your finger. A properly tensioned blade should produce a clear, high-pitched “ping” sound. If it sounds dull or thuddy, it’s too loose.

- Visual Check: Look down the length of the blade. It should appear straight and not bowed.

- Feel the Resistance: When you try to flex the blade slightly with your thumb, it should feel stiff and resist bending.

It might take a few tries to get the feel for the right tension. Don’t be afraid to adjust it. A properly tensioned blade is safer and cuts much more effectively. For more on tool tensioning, resources like Popular Mechanics offer excellent practical advice.

Mastering the Cut: Hacksaw Technique for Metal

You’ve got the right blade, and your hacksaw is ready. Now, let’s talk about the actual cutting. It’s not just about brute force; technique is key to achieving those clean, precise cuts.

Setting Up Your Workpiece

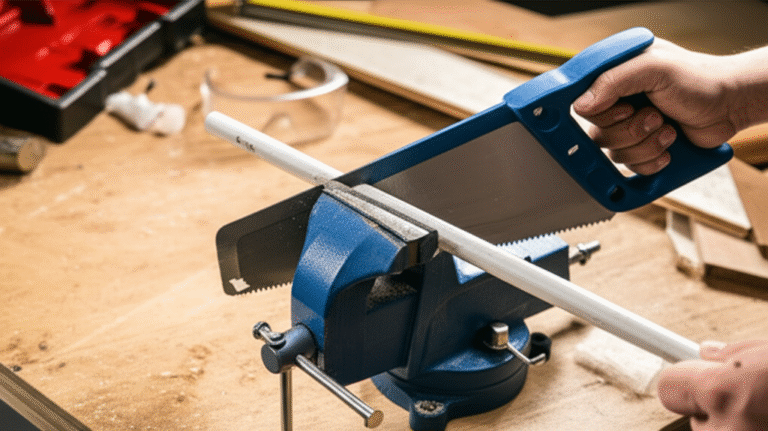

Secure your material firmly. This is non-negotiable for safety and accuracy.

- Use a Vise: The best way to hold metal for cutting is in a sturdy vise. Position the vise so the cut line is just slightly proud of the jaws, allowing the blade to pass through without hitting the vise itself.

- Clamps: If a vise isn’t available, use strong clamps to secure the metal to a workbench or sturdy surface. Ensure the workpiece is stable and won’t move during the cut.

- Marking Your Cut: Use a marker or scribe to clearly mark your cut line. This gives you a visual guide.

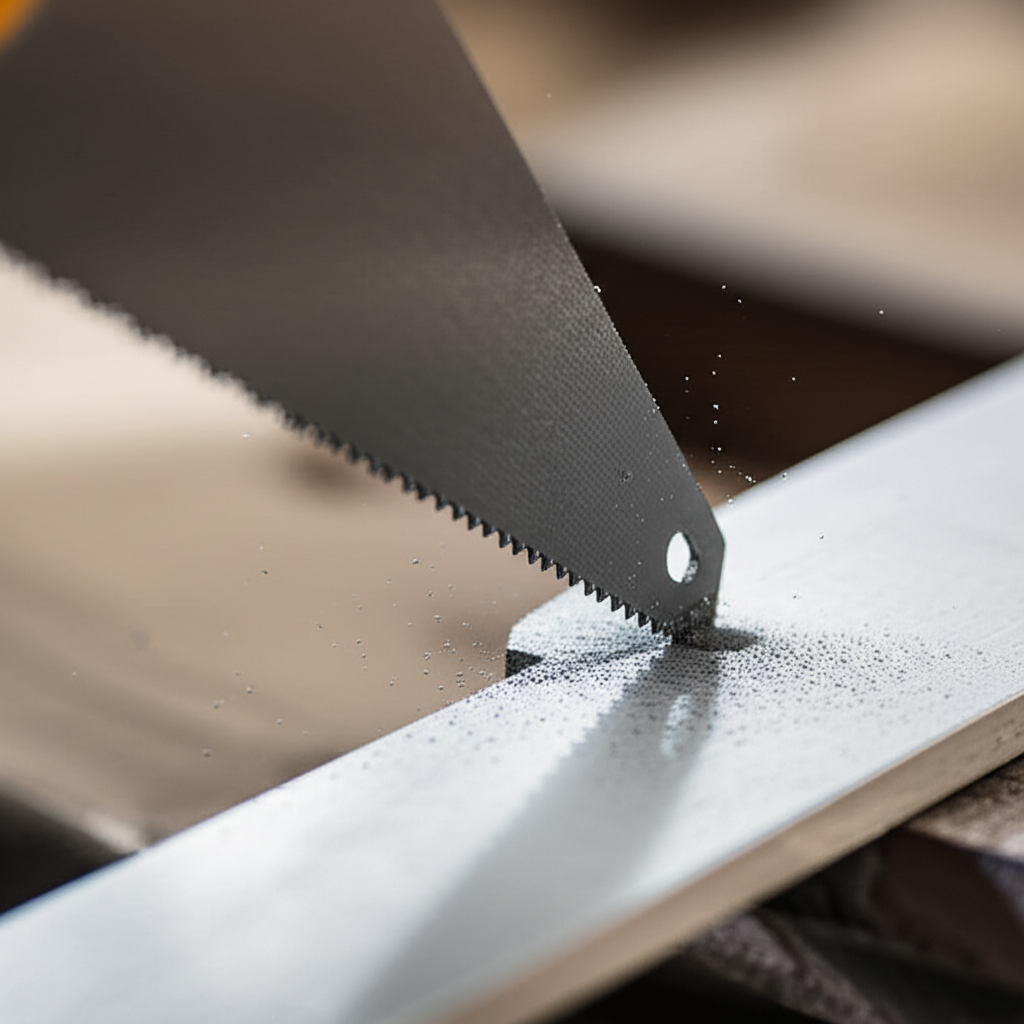

The Cutting Stroke: Smooth and Steady

Think of your cutting motion like a smooth, controlled push and pull.

- Start the Cut: Place the hacksaw blade on your marked line. Use your thumb as a guide against the blade to start a small notch. This prevents the blade from jumping.

- Apply Forward Pressure: Apply firm, steady pressure on the forward stroke (when the teeth are cutting). Let the blade do the work.

- Release Pressure on Return Stroke: Lift the hacksaw slightly or reduce pressure on the backward stroke. This prevents the teeth from dulling or breaking on the return.

- Use the Full Blade Length: Make long, sweeping strokes using as much of the blade’s length as possible. This distributes wear evenly across the teeth and makes cutting faster.

- Maintain a Consistent Angle: Try to keep the hacksaw blade at a consistent angle relative to the workpiece. For most metals, a slight angle forward is natural.

- Keep the Blade Straight: Don’t let the blade twist or bend. If it starts to wander, ease up on the pressure and try to guide it back.

What to Do If the Blade Skips

If your blade starts to skip across the metal, it’s usually a sign of one of these issues:

- Blade is too loose: Re-tension the blade.

- Not enough teeth engaged: You might be using a blade with too few TPI for the material, or you’re not applying enough forward pressure.

- Blade is dull: It might be time for a new blade.

- Workpiece is not secured: Make sure your material is clamped down tightly.

A good starting point is to apply light pressure initially until a kerf (groove) is established, then increase pressure. For more detailed insights into sharpening and blade care, resources from organizations like the Occupational Safety and Health Administration (OSHA) highlight the importance of maintaining tools for safety.

Blade Maintenance and Safety Tips

Taking care of your blades and practicing safe habits will ensure longevity and prevent injuries.

Blade Maintenance

Hacksaw blades are consumables, meaning they will eventually wear out and need replacing. However, you can extend their life:

- Keep them clean: Wipe down blades after use to remove metal shavings and debris.

- Store them properly: Keep blades in a dry place, ideally in their original packaging or a blade storage box, to prevent rust and damage.

- Replace dull blades: A dull blade makes cutting harder, increases fatigue, and is more likely to break. If you find yourself pressing excessively hard or the blade isn’t cutting effectively, it’s time for a new one.

Safety First!

Working with sharp tools requires respect and caution.

- Always wear safety glasses: Metal shavings can fly off unexpectedly.

- Wear gloves: Protect your hands from sharp edges and potential cuts.

- Secure your workpiece: Never try to cut freehand.

- Keep fingers away from the blade: Be mindful of where your hands are at all times.

- Don’t force the blade: If it’s not cutting, check your TPI, tension, or consider a new blade. Forcing it is a recipe for breakage or injury.

- Let the blade do the work: Focus on a smooth, consistent stroke rather than brute force.

When to Replace Your Hacksaw Blade

Hacksaw blades don’t last forever. Knowing when to swap one out is part of efficient cutting.

- Visible Wear: If the teeth look rounded or worn down.

- Slow Cutting: If it takes significantly more effort and time to make a cut than it used to.

- Skipping or Slipping: If the blade consistently skips over the material, even with proper tension and technique.

- Blade Breakage: If a blade breaks, it’s a clear sign it was either over-tensioned, improperly used, or simply worn out.

Troubleshooting Common Hacksaw Problems

Even with the right blade, you might encounter issues. Here’s how to tackle them.

| Problem | Possible Cause | Solution |

|---|---|---|

| Blade breaks frequently | Blade too loose or too tight; forcing the cut; wrong TPI for material; blade is old/worn. | Check blade tension; use proper stroke pressure; ensure correct TPI; replace old blades. |

| Blade skips | Blade too loose; not enough teeth engaged (wrong TPI); workpiece not secured; starting cut improperly. | Increase blade tension; use a blade with more TPI for thin materials; clamp workpiece securely; start cut with thumb guide. |

| Rough or jagged cut | Blade is dull; wrong TPI for material; blade is too loose; inconsistent cutting stroke. | Replace blade; use correct TPI; check tension; maintain a smooth, consistent stroke. |

| Blade gets clogged with metal | Too many teeth engaged (wrong TPI for material); not clearing chips effectively. | Use a blade with fewer TPI for thicker materials; try a lighter stroke or brush away chips periodically. |

Frequently Asked Questions (FAQ)

Q1: What is the best TPI for cutting all types of metal?

There isn’t one single “best” TPI for all metals. The ideal TPI depends on the thickness of the metal. For general-purpose cutting of various metal thicknesses, an 18 TPI or 24 TPI bi-metal blade is often a good starting point.

Q2: Can I use a hacksaw blade meant for wood on metal?

No, you should not. Wood blades have fewer, larger teeth designed to cut wood fibers. Using them on metal will quickly dull or break the teeth and won’t cut effectively. Always use blades specifically designed for metal.

Q3: How do I know if my hacksaw blade is installed correctly?

The teeth should always face away from the handle, towards the front of the hacksaw. The blade should also be taut, like a guitar string, producing a “ping” when plucked.

Q4: Is it okay to use a lot of force when cutting metal?

No, it’s generally not recommended. Forcing the blade can cause it to bend, break, or skip, leading to a poor cut and potential injury. Let the sharp teeth and a smooth, steady stroke do the work.

Q5: How often should I replace my hacksaw blade?

Hacksaw blades are consumables. You should replace a blade when it becomes dull, starts