Tuning a chainsaw carb can seem complex. But with the right steps, it’s manageable.

A well-tuned chainsaw carb ensures your chainsaw runs smoothly and efficiently. It can help extend the life of your tool and make your work easier. Whether you use your chainsaw for cutting firewood or trimming trees, keeping the carburetor in good shape is essential.

This guide will walk you through the process, making it simple to understand and follow. By the end, you’ll feel confident in adjusting your chainsaw carb like a pro. Ready to get started? Let’s dive into the details and get your chainsaw running at its best.

Credit: www.youtube.com

Introduction To Chainsaw Carburetors

Welcome to our guide on tuning chainsaw carburetors. A carburetor is a vital part of your chainsaw. It ensures the engine gets the right mix of fuel and air. Proper tuning keeps your chainsaw running smoothly.

Purpose Of Carburetors

Carburetors have a specific purpose. They mix fuel and air in the right ratio. This mixture is essential for engine performance. Without a carburetor, the engine cannot run.

Here are the main functions of a carburetor:

- Mixing fuel and air

- Adjusting the ratio based on engine needs

- Ensuring the engine gets enough fuel

- Supporting different engine speeds

Importance Of Proper Tuning

Tuning your carburetor is crucial. It affects how well your chainsaw works. Poor tuning can lead to engine problems. It may also reduce the lifespan of your chainsaw.

Here are some benefits of proper tuning:

- Better engine performance

- Reduced fuel consumption

- Longer engine life

- Less smoke and emissions

Proper tuning also ensures safety. An improperly tuned chainsaw can be dangerous. It may stall or run erratically.

Understanding your chainsaw carburetor is the first step. Proper tuning follows. Both are key to a well-running chainsaw.

Tools Needed For Tuning

To properly tune a chainsaw carburetor, you need the right tools. Using the correct tools not only makes the job easier but also ensures accuracy and safety. Below, you will find a list of essential tools and safety equipment required for tuning a chainsaw carburetor.

Essential Tools

First, you need a screwdriver. A flathead screwdriver is typically used. Some chainsaws may need a special carburetor adjustment tool. Check your chainsaw’s manual to confirm. You will also need a tachometer. This device measures the engine’s RPM. It helps you adjust the carburetor precisely.

An air filter is also essential. A clean air filter ensures proper air flow. This affects the carburetor’s performance. Finally, keep a spark plug wrench handy. This tool helps you check and adjust the spark plug.

Safety Equipment

Safety is crucial when working with chainsaws. Always wear safety gloves. They protect your hands from sharp edges and hot surfaces. Safety goggles are also important. They shield your eyes from flying debris.

Hearing protection is necessary too. Chainsaws are loud. Prolonged exposure can damage your hearing. Use earplugs or earmuffs. Lastly, wear sturdy footwear. Steel-toed boots offer the best protection. They shield your feet from falling objects.

Preparing The Chainsaw

Before tuning your chainsaw carburetor, you must prepare the chainsaw. Proper preparation ensures safety and efficiency. This involves cleaning the chainsaw and inspecting its components.

Cleaning The Chainsaw

First, clean your chainsaw to remove dirt and debris. Use a brush to clear away dust from the exterior. Pay special attention to the air filter. A clean air filter helps the carburetor function properly. If the filter is very dirty, replace it. Clean around the carburetor area to avoid dirt entering during tuning.

Inspecting Components

Next, inspect the chainsaw components. Check the spark plug for wear and damage. Replace it if necessary. Look at the fuel lines to ensure they are not cracked or leaking. Examine the fuel filter and replace it if it looks dirty. Also, check the throttle linkage to ensure smooth movement. These inspections help the chainsaw run smoothly after tuning.

Credit: www.youtube.com

Identifying Carburetor Screws

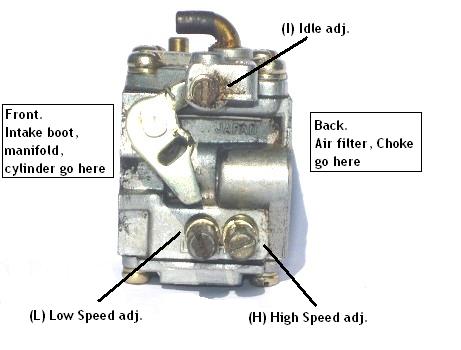

Understanding the different carburetor screws on a chainsaw is crucial for proper tuning. Each screw plays a specific role in managing the chainsaw’s performance. Identifying these screws correctly can make the tuning process much easier and more effective.

High And Low-speed Screws

The high-speed screw and low-speed screw control the fuel mixture at different engine speeds. The high-speed screw adjusts the fuel mixture for the engine when it is running at full throttle. This screw is often marked with an “H”. The low-speed screw, marked with an “L”, controls the fuel mixture when the engine is idling or running at low speeds.

To identify these screws, look for markings near the carburetor. Most carburetors have letters or symbols to denote these screws. Adjusting them properly ensures your chainsaw runs efficiently at all speeds.

Idle Speed Screw

The idle speed screw manages the engine’s idle speed. It is often marked with a “T” or “LA”. This screw is crucial for maintaining the chainsaw’s idle without stalling. Turning this screw clockwise increases the idle speed, while turning it counterclockwise decreases the idle speed.

To locate the idle speed screw, find the screw nearest the throttle linkage. Proper adjustment of this screw ensures that the chainsaw runs smoothly when not cutting.

Here is a simple table to summarize the functions of these screws:

| Screw | Function | Marking |

|---|---|---|

| High-Speed | Adjusts fuel at full throttle | H |

| Low-Speed | Adjusts fuel at low speeds | L |

| Idle Speed | Manages engine idle speed | T or LA |

Understanding these screws and their functions is the first step to tuning your chainsaw carburetor effectively. Proper adjustment can significantly improve your chainsaw’s performance.

Adjusting The Idle Speed

Adjusting the idle speed of your chainsaw is crucial. It ensures the chainsaw runs smoothly and efficiently. Proper adjustment prevents stalling and excessive fuel consumption. This section will guide you through the steps to adjust the idle speed.

Setting The Base Idle

First, locate the idle speed screw on your chainsaw. It is usually marked with the letter “T”. Turn the screw clockwise until it stops. Then, turn it counterclockwise one full turn. This sets the base idle speed.

Fine-tuning The Idle

Start the chainsaw and let it warm up. If the chain moves at idle, turn the screw counterclockwise. Do this in small increments until the chain stops moving. If the chainsaw stalls, turn the screw clockwise slightly. Continue adjusting until the chainsaw idles smoothly without the chain moving.

Tuning The Low-speed Screw

Tuning the low-speed screw on your chainsaw carburetor is crucial for its smooth operation. This adjustment ensures the chainsaw runs efficiently at idle and low speeds. Proper tuning can prevent engine stalling and improve fuel efficiency. Let’s dive into the steps involved in tuning the low-speed screw.

Initial Adjustments

To begin, locate the low-speed screw on your chainsaw. It is usually labeled with an “L” and is one of the three adjustment screws on the carburetor. Use a small screwdriver for this task.

| Step | Action |

|---|---|

| 1 | Turn the low-speed screw clockwise until it stops. |

| 2 | Back it out by one and a half turns. |

These initial adjustments set a baseline for fine-tuning. Do not over-tighten the screw. This can damage the carburetor.

Testing Performance

Start the chainsaw and let it warm up for a few minutes. The engine should run smoothly at idle. If it stalls, adjust the low-speed screw slightly.

- Turn the low-speed screw clockwise to make the mixture leaner.

- Turn the low-speed screw counterclockwise to make the mixture richer.

Perform small adjustments, no more than 1/8 turn at a time. Listen to the engine’s response. A lean mixture can cause the engine to rev higher but may lack power. A rich mixture may make the engine run sluggishly.

Once you find the sweet spot, where the engine idles smoothly without stalling, you have successfully tuned the low-speed screw. This adjustment will ensure your chainsaw runs efficiently and reduces the risk of engine damage.

Tuning The High-speed Screw

Tuning the high-speed screw of your chainsaw carburetor is crucial for optimal performance. The high-speed screw controls the fuel mixture when the engine is running at full throttle. Proper tuning ensures your chainsaw runs smoothly, delivers maximum power, and reduces fuel consumption.

Initial Adjustments

Before starting, ensure your chainsaw is on a flat surface. Locate the high-speed screw, usually marked with an “H”. Turn the screw clockwise until it stops. Be gentle to avoid damage. Then, turn it counterclockwise 1.5 turns. This is your starting point.

Testing Performance

Start the chainsaw and let it warm up for a few minutes. Engage the throttle to reach full speed. Listen to the engine. If it sputters or sounds rough, adjust the high-speed screw. Turn it clockwise to lean the mixture and counterclockwise to enrich it.

Make small adjustments, about 1/8 turn at a time. Test the performance after each adjustment. Continue until the engine runs smoothly at full throttle. Ensure the chainsaw accelerates quickly without hesitation.

Final Checks And Adjustments

Once you have adjusted the carburetor of your chainsaw, it is crucial to perform final checks and adjustments. These steps ensure your chainsaw operates safely and efficiently. This section will guide you through the necessary steps to finalize your chainsaw tuning.

Rechecking Idle Speed

First, you need to recheck the idle speed. Start the chainsaw and let it idle. The chain should not move while idling. If the chain moves, turn the idle screw counterclockwise to lower the idle speed. Continue adjusting until the chain remains stationary at idle.

Use a tachometer if available. It helps measure the exact RPM. Refer to your chainsaw’s manual for the recommended idle speed range. Ensure the engine runs smoothly without any sputtering or stalling.

Performing A Test Cut

Next, perform a test cut to verify the adjustments. Choose a piece of wood for this test. Engage the chain brake and start the chainsaw. Disengage the brake and make a cut.

- If the chainsaw cuts smoothly, your adjustments are correct.

- If it bogs down or stalls, you need to readjust the carburetor.

- If the saw produces too much smoke, it may be running too rich.

Repeat the test cut after each adjustment. Ensure the chainsaw operates efficiently without any issues.

| Issue | Adjustment |

|---|---|

| Chain moves at idle | Lower idle speed |

| Sputtering or stalling | Adjust idle or mixture screws |

| Excessive smoke | Lean the mixture |

Always wear safety gear during these checks. Safety goggles, gloves, and ear protection are essential. Following these steps ensures your chainsaw is in optimal condition.

Maintenance Tips

Maintaining a chainsaw carburetor is essential for its performance and longevity. Regular upkeep helps prevent costly repairs and ensures your chainsaw runs smoothly. This section outlines practical maintenance tips for your chainsaw carburetor.

Regular Cleaning

Regular cleaning keeps your chainsaw carburetor in good shape. Remove dirt and debris from the air filter. A clean air filter ensures proper airflow. Use a brush to clean the carburetor’s exterior. This prevents build-up that can clog the system. Always clean the fuel lines and tank. This ensures no blockages that can disrupt fuel flow.

Periodic Inspections

Periodic inspections help spot issues early. Check the carburetor for loose screws and bolts. Tighten them as needed. Inspect the gaskets for wear and tear. Replace worn gaskets to avoid leaks. Look at the fuel and air lines for cracks. Replace any damaged lines to maintain proper function.

Credit: www.scribd.com

Frequently Asked Questions

How Do I Know If My Chainsaw Carb Needs Tuning?

If your chainsaw stalls, sputters, or lacks power, it may need tuning. Irregular idling or poor acceleration are also signs.

What Tools Are Required To Tune A Chainsaw Carb?

You will need a screwdriver, tachometer, and a carburetor adjustment tool. Always refer to your manual for specific tools.

How Often Should I Tune My Chainsaw Carb?

Tune your chainsaw carburetor at least once a year or whenever you notice performance issues.

Can I Tune My Chainsaw Carb Myself?

Yes, you can tune your chainsaw carburetor yourself. Follow the manufacturer’s guidelines and safety instructions.

Conclusion

Tuning a chainsaw carb is crucial for smooth operation. Follow the steps closely. Regular maintenance ensures your chainsaw works efficiently. A well-tuned carb helps with better fuel efficiency. It also extends the lifespan of your chainsaw. Always use the right tools for tuning.

Safety should be your top priority. Wear protective gear and work in a safe environment. With these tips, you can keep your chainsaw in top condition. Happy cutting!