Tuning a chainsaw carburettor is essential for its optimal performance. With the right adjustments, your chainsaw will run smoothly and efficiently.

A well-tuned carburettor ensures your chainsaw starts easily and cuts effectively. It might seem complex, but with some basic knowledge, you can handle it. Carburettors manage the air-fuel mixture in the engine. If the mix is off, the chainsaw can stall, run poorly, or even get damaged.

This guide will walk you through the steps to fine-tune your chainsaw’s carburettor. You’ll learn how to identify problems, make adjustments, and test the results. With a few simple tools and some patience, you can keep your chainsaw in top shape. Ready to get started? Let’s dive in.

Credit: www.youtube.com

Safety Precautions

Tuning a chainsaw carburettor can be tricky. But ensuring safety is crucial. Here are some important safety precautions to keep in mind. By following these steps, you will avoid accidents and stay safe.

Protective Gear

Before tuning your chainsaw carburettor, wear the right protective gear. This is essential for your safety.

- Safety glasses: Protects your eyes from flying debris.

- Gloves: Keeps your hands safe from cuts and chemicals.

- Ear protection: Chainsaws are loud. Protect your hearing.

- Helmet: Shields your head from accidents.

- Long sleeves and pants: Prevents cuts and scratches.

Work Area Preparation

Prepare your work area before you start. A well-prepared space ensures safety.

- Clear the area: Remove any obstacles or tripping hazards.

- Proper lighting: Ensure the area is well-lit. You need to see clearly.

- Ventilation: Work in a well-ventilated area. Avoid inhaling fumes.

- Stable surface: Place the chainsaw on a stable, flat surface.

- Keep tools handy: Have all necessary tools within reach.

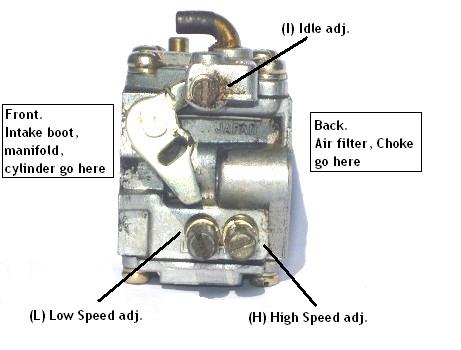

Identifying Carburettor Parts

Tuning your chainsaw carburettor can seem daunting. But understanding its parts makes it easier. This guide helps you identify key carburettor parts. Once you know them, you can adjust them for optimal performance.

High And Low-speed Screws

The high and low-speed screws control fuel flow. The high-speed screw adjusts fuel at full throttle. The low-speed screw adjusts fuel at idle and low speeds. Turning these screws clockwise leans the fuel mixture. Turning them counterclockwise enriches the fuel mixture.

Here’s a simple way to find them:

- Look for two screws close to each other.

- They are often labeled “H” and “L”.

- Refer to the chainsaw manual for exact locations.

Idle Speed Screw

The idle speed screw controls the engine’s idle speed. It determines how fast the engine runs without throttle input. This screw is crucial for smooth idling.

To find the idle speed screw:

- Look for a single screw near the throttle linkage.

- It is often labeled “T” or “I”.

- Again, consult the manual for precise identification.

Adjusting the idle speed screw clockwise increases idle speed. Turning it counterclockwise decreases idle speed. Ensure the engine runs smoothly at idle after adjustment.

Understanding these parts simplifies tuning your chainsaw. Proper adjustment keeps your chainsaw running efficiently and safely.

Initial Carburettor Settings

Properly tuning a chainsaw carburettor ensures it runs smoothly. The initial settings are crucial. These settings help balance the fuel and air mix. Always refer to your chainsaw’s manual for specific instructions. Let’s dive into the initial carburettor settings.

Factory Settings

Factory settings are the default adjustments set by the manufacturer. These settings are a good starting point. They ensure your chainsaw runs at a basic level. Locate the carburettor screws on your chainsaw. Typically, there are three screws: H (high speed), L (low speed), and T (idle). Turn these screws to the factory settings. Usually, this means turning them all the way in, then turning them out a specific number of turns. Check your manual for exact numbers.

Setting Baseline Adjustments

Baseline adjustments fine-tune the factory settings. Start your chainsaw and let it warm up. Adjust the L screw first. Turn it slowly until the engine runs smoothly at low speed. Next, adjust the H screw for high speed. Again, turn it until the engine runs smoothly. Finally, adjust the T screw. This controls the idle speed. Turn it until the chain stops moving at idle. Make sure the engine runs smoothly throughout all speed ranges.

Adjusting The Low-speed Screw

Adjusting the low-speed screw on your chainsaw carburettor ensures the engine runs smoothly at idle. It helps the chainsaw to start easily and perform efficiently. Follow these steps for optimal adjustment.

Finding The Optimal Setting

To find the optimal setting for the low-speed screw, you need to locate it first. Usually, it’s marked as ‘L’ on the carburettor. Turn it clockwise until it lightly seats. Then, turn it counterclockwise about one and a half turns.

| Step | Action |

|---|---|

| 1 | Locate the low-speed screw (marked ‘L’). |

| 2 | Turn the screw clockwise until it lightly seats. |

| 3 | Turn the screw counterclockwise one and a half turns. |

This initial setting is a good starting point. Fine-tune it by adjusting in small increments.

Testing Low-speed Performance

Start the chainsaw and let it idle. Listen to the engine. It should run smoothly without sputtering or stalling. If the engine sputters, turn the low-speed screw clockwise slightly. If it races or stalls, turn the screw counterclockwise.

- Turn the screw in small increments.

- Let the engine run for a few seconds.

- Listen to the changes in engine sound.

Repeat these steps until the engine runs smoothly at idle. A well-adjusted low-speed screw ensures your chainsaw performs efficiently and starts easily. This simple adjustment can save time and effort in your tasks.

Adjusting The High-speed Screw

Adjusting the high-speed screw on your chainsaw carburettor is essential. This adjustment ensures that your chainsaw runs efficiently. It also helps prevent engine damage.

Achieving Maximum Rpm

To achieve maximum RPM, you need to turn the high-speed screw. Start by turning it clockwise until it seats lightly. Then, turn it counterclockwise to the manufacturer’s recommended setting.

Now, start the chainsaw and let it warm up. Once warm, press the throttle trigger fully. Adjust the high-speed screw slowly. Turn it clockwise until the engine reaches its highest speed. Be careful not to over-tighten the screw.

Use a tachometer to check the RPM. The RPM should not exceed the manufacturer’s specifications. This ensures that your chainsaw operates at its peak performance.

Avoiding Engine Damage

Over-adjusting the high-speed screw can lead to engine damage. Running the engine too lean can cause overheating. This can result in a seized piston or damaged cylinder.

To avoid this, always follow the manufacturer’s guidelines. Make small adjustments and check the engine’s response. If the engine sounds rough or is smoking, readjust the screw.

Keep the air filter clean. A dirty air filter can affect the air-fuel mixture. This can make it harder to adjust the high-speed screw correctly.

Regular maintenance of the chainsaw is crucial. It helps keep the carburettor in good condition. This reduces the risk of engine damage.

Credit: www.scribd.com

Setting The Idle Speed

Setting the idle speed of your chainsaw carburettor ensures it runs efficiently and safely. An improperly set idle speed can lead to poor performance and potential safety hazards. This section will guide you through the steps to adjust the idle speed accurately.

Adjusting Idle Rpm

Begin by locating the idle adjustment screw on your chainsaw carburettor. This screw is often marked with an “I” or “T”. Use a screwdriver to turn the screw clockwise to increase the RPM or counterclockwise to decrease it.

- Start your chainsaw and let it run.

- Turn the idle screw slowly.

- Listen for changes in engine speed.

- Adjust until the chainsaw idles smoothly.

Ensuring Smooth Idle

A smoothly idling chainsaw is crucial for both performance and safety. After setting the idle RPM, ensure the chainsaw does not stall or run too fast.

- Check if the chain remains stationary when idling.

- Listen for consistent engine sounds.

- Make minor adjustments as needed.

Test the chainsaw by revving the engine and returning to idle. The engine should return smoothly without stalling.

| Adjustment | Action |

|---|---|

| Increase RPM | Turn idle screw clockwise |

| Decrease RPM | Turn idle screw counterclockwise |

By following these steps, you ensure your chainsaw runs efficiently. Proper maintenance of the idle speed extends the life of your tool and enhances safety during use.

Final Testing

Once you have adjusted your chainsaw carburettor, the next step is crucial. Final testing ensures your chainsaw runs smoothly and efficiently. This stage involves checking the saw under actual working conditions. Proper testing can help you spot any issues that need further adjustments. Let’s dive into the steps for final testing.

Test Cuts

Start by making a few test cuts. Use a piece of wood to see how the chainsaw performs. Ensure the saw cuts smoothly and does not stall. Listen to the engine. It should sound steady and strong. If the engine sputters, adjustments might be needed. Observe the cutting speed. It should be consistent. Also, check for any unusual smoke. Excess smoke indicates a problem with the fuel mixture.

Fine-tuning Adjustments

After your test cuts, fine-tuning might be required. Adjust the carburettor screws slightly. Turn them in small increments. Test the saw after each adjustment. This ensures you do not over-adjust. Focus on the idle speed. It should be stable and not too high or low. Check the acceleration. The chainsaw should respond quickly when you press the throttle. Make sure there is no lag. If needed, consult your chainsaw manual for specific settings.

Credit: www.youtube.com

Maintenance Tips

Proper maintenance of your chainsaw carburettor ensures smooth operation and longevity. Regular upkeep can prevent common issues and improve performance. Let’s dive into some essential maintenance tips for your chainsaw carburettor.

Regular Cleaning

Regular cleaning of the carburettor is crucial. Dirt and debris can clog the tiny passages, affecting performance. Follow these steps:

- Turn off the chainsaw and let it cool.

- Remove the air filter cover and the air filter.

- Use a brush to remove dirt from the air filter.

- Spray carburettor cleaner on the carburettor body.

- Wipe off the cleaner with a clean cloth.

Repeat this process every few weeks to keep the carburettor clean.

Periodic Adjustments

Periodic adjustments of the carburettor settings can optimize performance. Adjusting the idle speed and fuel mixture is necessary. Here’s a simple guide:

- Locate the adjustment screws on the carburettor.

- Turn the idle speed screw clockwise to increase speed.

- Turn the idle speed screw counterclockwise to decrease speed.

- Adjust the high-speed screw for fuel mixture. Turn it slowly until the engine runs smoothly.

Adjusting these settings every season ensures the chainsaw runs efficiently.

Maintaining your chainsaw carburettor does not have to be complicated. Regular cleaning and periodic adjustments can keep your chainsaw in top condition.

Troubleshooting

Troubleshooting your chainsaw carburettor can save you time and money. Understanding common issues and knowing when to seek professional help is crucial. This section will guide you through some common problems and provide tips on when to get expert assistance.

Common Issues

Several issues can affect your chainsaw carburettor. A dirty carburettor can cause the engine to run poorly. To fix this, clean the carburettor with a carburettor cleaner.

Another issue is a clogged fuel filter. This can prevent fuel from reaching the engine. Replace the fuel filter if it’s clogged.

An incorrect fuel mixture can also cause problems. Ensure you mix fuel and oil in the right proportions.

When To Seek Professional Help

Sometimes, fixing a chainsaw carburettor can be complex. If you have tried basic troubleshooting without success, it might be time to get professional help.

If the engine still runs poorly after cleaning and adjusting, seek expert advice. Persistent issues with the carburettor may indicate deeper problems. A professional can diagnose and fix these issues effectively.

Remember, safety first. If you are unsure about any step, consult a professional.

Frequently Asked Questions

How Do I Adjust The Chainsaw Carburettor?

First, locate the carburettor adjustment screws. Turn the screws slowly to adjust the fuel mixture. Test the chainsaw and fine-tune as necessary.

Why Is My Chainsaw Running Rough?

A rough-running chainsaw often indicates a carburettor issue. Adjusting the carburettor can improve performance and smooth out the engine.

How Often Should I Tune My Chainsaw Carburettor?

Tune your chainsaw carburettor at least once a year. Regular tuning ensures optimal performance and prolongs the life of your chainsaw.

What Tools Do I Need To Tune A Chainsaw Carburettor?

You will need a screwdriver and a tachometer. These tools help you adjust the carburettor screws accurately and measure engine speed.

Conclusion

Tuning a chainsaw carburettor can seem daunting at first. But with patience, you can do it. Start by adjusting the idle speed. Then, fine-tune the low-speed and high-speed screws. Listen to the engine’s sound. It tells you if adjustments are right.

Always check the manufacturer’s manual. It provides useful guidelines. Regular maintenance keeps your chainsaw running smoothly. A well-tuned carburettor ensures efficiency. Safety is crucial. Wear protective gear while working. Happy tuning!