Is More Teeth On A Hacksaw Blade Better? For most common cuts, a blade with fewer teeth per inch (TPI) is better for softer materials like wood or plastic, while more teeth are ideal for harder metals. The key is matching the TPI to your material for cleaner, faster cuts.

Hey there, DIYer! Ever stood in front of a wall of shiny hacksaw blades, feeling a little lost? You’re not alone. That little number on the package, the TPI, can seem like a secret code. Does more teeth mean a better cut? It’s a question I get asked a lot, and the truth is, it’s not quite that simple. But don’t worry, we’re going to break it down. Choosing the right hacksaw blade is like picking the right tool for any job – it makes everything easier and the results so much better. We’ll go from confused to confident, so you can tackle your next project with a smile. Ready to learn the genius tip that makes all the difference?

Understanding Hacksaw Blades: The Magic of TPI

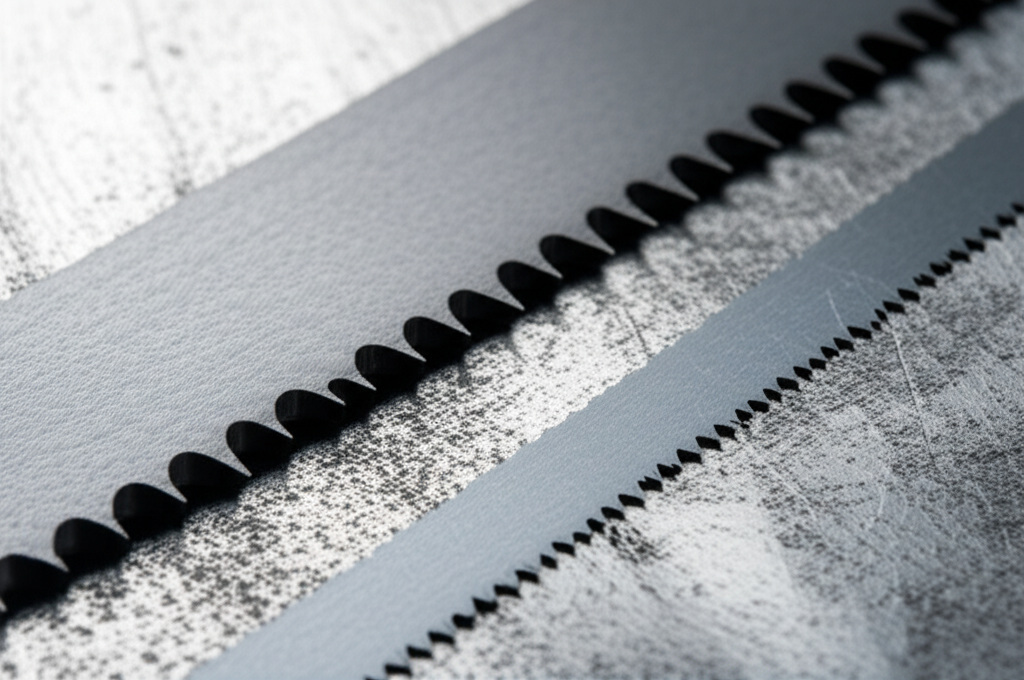

So, what exactly is TPI, and why should you care? TPI stands for Teeth Per Inch. It’s a simple measurement, but it tells you a lot about how a hacksaw blade will perform. Think of it like this: a blade with more teeth packed into each inch will create finer, smoother cuts, while a blade with fewer, larger teeth will cut more aggressively.

It’s not about having more teeth, but having the right number of teeth for the job. Using a blade with too many teeth on a thick piece of metal can clog up and make cutting a real struggle. Conversely, using a blade with too few teeth on a thin piece of plastic can snag and leave a rough, jagged edge.

At Capische, we believe that understanding your tools is the first step to mastering them. We want you to feel empowered, not intimidated. So, let’s dive into how TPI affects your cutting and how to pick the perfect blade every time.

The “More Teeth” Myth: When It Helps and When It Hinders

Let’s tackle that big question head-on: Is more teeth on a hacksaw blade better? The short answer is: it depends entirely on the material you’re cutting.

Think of it like using different grit sandpaper. A fine grit (lots of tiny particles) is for smoothing, while a coarse grit (fewer, larger particles) is for rapid material removal. Hacksaw blades work on a similar principle.

Here’s a quick breakdown:

- More Teeth (Higher TPI): These blades are designed for thinner materials. The smaller, more numerous teeth create a smoother finish and prevent the blade from snagging or chipping the material.

- Fewer Teeth (Lower TPI): These blades have larger, more aggressive teeth. They’re great for cutting thicker materials because the larger gullets (the spaces between teeth) help clear away debris, preventing the blade from getting clogged.

So, while “more teeth” sounds appealing, it’s only “better” when matched with the right material. Using a high-TPI blade on thick metal is like trying to cut a steak with a butter knife – it’s slow, inefficient, and frustrating.

Choosing the Right TPI for Your Material: A Simple Guide

To help you make the best choice, we’ve put together a handy guide. Remember, these are general guidelines, and you might find slight variations depending on the specific blade manufacturer.

The general rule of thumb is to have at least two, and preferably three, teeth in contact with the material at all times. This ensures a clean, controlled cut and prevents the teeth from stripping or breaking.

Here’s a look at common materials and the TPI you’ll want to reach for:

| Material Type | Typical Thickness | Recommended TPI | Why it Works |

|---|---|---|---|

| Thin Metal (e.g., sheet metal, conduit, thin pipe) | Under 1/8 inch (3mm) | 24-32 TPI | Fine teeth provide a smooth finish and prevent snagging on thin stock. |

| Medium Metal (e.g., bolts, rebar, thicker pipe) | 1/8 inch to 1/4 inch (3mm to 6mm) | 18-24 TPI | A good balance for cutting through moderate thickness without excessive clogging. |

| Thick Metal (e.g., solid bar stock, heavy angle iron) | Over 1/4 inch (6mm) | 14-18 TPI | Larger teeth and wider gullets clear chips efficiently, preventing the blade from binding. |

| Plastic (e.g., PVC pipe, acrylic sheets) | All thicknesses | 18-24 TPI | Teeth should be fine enough to avoid chipping or melting the plastic, but aggressive enough to cut effectively. |

| Wood (Softwoods, hardwoods) | All thicknesses | 10-18 TPI | Larger teeth are excellent for wood, providing faster cuts and good chip clearance. For very fine woodworking, you might see blades with higher TPI. |

You might also see blades with bi-metal construction. These are a great investment as they combine a flexible spring steel back with high-speed steel teeth, making them more durable and able to withstand tougher jobs. For more on tool materials, you can check out resources like NIST’s Materials Science and Engineering section, which offers deep insights into material properties.

The “Genius Tip”: How to Use TPI to Your Advantage

Here’s the genius tip that will elevate your cutting game: Always aim for a blade that has at least two to three teeth engaged with the material at any given time.

This simple principle is the key to achieving clean, efficient cuts and prolonging the life of your blade.

- Too Few Teeth Engaged: If you’re cutting thin metal with a low-TPI blade (like 14 TPI), you might only have one tooth biting into the material. This means each tooth is taking on a lot of stress, leading to premature wear, broken teeth, and a rough cut.

- Too Many Teeth Engaged: If you’re cutting thick metal with a high-TPI blade (like 32 TPI), all those tiny teeth will get clogged with metal chips. This makes it incredibly difficult to saw, generates excessive heat, and can quickly dull or break the blade.

How to apply this tip:

- Measure your material’s thickness. This is the most crucial first step.

- Consult the TPI guide (like the table above) to find the recommended range for that thickness.

- Select a blade within that TPI range. If your material is on the thinner side of a category, lean towards the higher TPI. If it’s on the thicker side, lean towards the lower TPI.

- For example: If you’re cutting a piece of metal that’s exactly 1/8 inch thick, you could use either an 18 TPI or a 24 TPI blade. For a smoother finish, go with 24 TPI. For a faster cut, go with 18 TPI.

This approach ensures that the load is distributed evenly across multiple teeth, leading to a more controlled cut, less effort for you, and a longer-lasting blade. It’s a small adjustment that makes a world of difference!

Beyond TPI: Other Factors for a Perfect Cut

While TPI is king when it comes to choosing the right blade, a few other factors contribute to a successful cut. Let’s look at them:

Blade Material

Hacksaw blades are typically made from one of two materials:

- High-Speed Steel (HSS): These blades are harder and can withstand higher temperatures, making them suitable for cutting harder metals. However, they can be more brittle.

- Bi-Metal: This is the most common and recommended type for general use. Bi-metal blades combine a flexible spring steel back with hardened HSS teeth. This gives you the best of both worlds: durability, flexibility, and sharp, long-lasting teeth. They are less likely to shatter.

For most DIYers, a bi-metal blade is the way to go. You can find excellent resources on metal properties and their applications on sites like The American Welding Society (AWS), which often discusses material behavior in cutting and joining processes.

Blade Tension

This is crucial! A hacksaw blade needs to be properly tensioned in the frame. A blade that’s too loose will wander, making it hard to cut straight and increasing the risk of the blade snapping. A blade that’s too tight can also snap.

How to tension:

- Place the blade in the hacksaw frame, ensuring the teeth are facing away from you (so you cut on the push stroke).

- Tighten the tensioning screw or wing nut on the handle until the blade is taut.

- A good test is to pluck the blade. It should make a “ping” sound, not a dull “thud.”

Many modern hacksaws have a lever or a quick-release mechanism that makes tensioning easier and more consistent.

Blade Angle and Stroke

The angle at which you hold the blade and the length of your stroke also matter.

- Angle: Hold the hacksaw at a slight angle to the workpiece, usually around 45-60 degrees. This allows more teeth to engage and provides a smoother cut.

- Stroke: Use long, steady strokes, engaging the full length of the blade. Let the blade do the work; don’t force it. Apply firm pressure on the forward stroke (when cutting) and ease up on the return stroke.

Remember, the goal is a controlled, consistent motion. This approach minimizes binding and reduces the strain on both you and the blade.

Common Hacksaw Blade Mistakes to Avoid

Even with the right TPI, a few common mistakes can turn a simple cut into a frustrating ordeal. Let’s make sure you’re not making these:

- Using the wrong TPI: We’ve covered this, but it bears repeating! Using a blade with too many or too few teeth is the number one culprit for bad cuts.

- Not tensioning the blade correctly: A loose blade is a dangerous blade and a poor cutter. Always ensure it’s taut.

- Cutting on the pull stroke: Always cut on the push stroke. This is how the blade is designed to work and prevents the blade from bending or breaking.

- Applying too much force: Let the teeth do the work. Forcing the saw will lead to broken teeth, a bent blade, and an uneven cut.

- Not using cutting fluid (for metal): For tougher metals, a bit of cutting fluid or oil can significantly reduce friction, keep the blade cool, and improve the cut quality. It also helps clear chips.

- Not securing the workpiece: Always clamp your material firmly in a vise or with clamps. A wobbly workpiece is impossible to cut accurately and safely.

Avoiding these pitfalls will save you time, frustration, and money on replacement blades.

When to Replace Your Hacksaw Blade

Even the best hacksaw blades wear out. Knowing when it’s time for a new one is part of being a smart DIYer.

Here are signs your blade needs replacing:

- Slow cutting: If it’s taking significantly longer to cut through materials you used to cut easily.

- Rough cuts: The cut edge is jagged, uneven, or shows signs of tearing rather than slicing.

- Excessive force required: You’re having to push much harder than usual to make progress.

- Broken teeth: If you see missing teeth along the blade, it’s time for a new one.

- Blade bending or wandering: While sometimes due to tension, a dull blade can also cause this.

Replacing a blade is simple and inexpensive, and it makes a huge difference in your cutting experience. Don’t push a dull blade; it’s not worth the frustration!

Frequently Asked Questions (FAQ)

Q1: What is the most versatile TPI for a hacksaw blade?

A1: For general DIY use, a bi-metal blade with 18 or 24 TPI is often the most versatile. This range covers a good variety of common materials like medium-thickness metal and plastics.

Q2: Can I use a hacksaw blade on wood?

A2: Yes, you can! Hacksaw blades with lower TPI (around 10-18 TPI) are designed for cutting wood and will work effectively. They have larger teeth that clear wood chips better than fine-toothed blades.

Q3: What happens if I use a blade with too many teeth on thick metal?

A3: If you use a high-TPI blade (like 32 TPI) on thick metal, the small teeth will get clogged with metal shavings. This causes the blade to bind, overheat, and can lead to broken teeth or a snapped blade. The cut will also be very slow and inefficient.

Q4: How do I know if my hacksaw blade is properly tensioned?

A4: A properly tensioned blade should feel taut. When you pluck it, it should make a clear “pinging” sound, similar to a guitar string, rather than a dull “thud.” It shouldn’t feel floppy or loose.

Q5: Is there a difference between a hacksaw blade for metal and one for wood?

A5: Yes, there is! Blades for metal typically have higher TPI (24-32) for finer cuts and are often made of bi-metal for durability. Blades for wood have lower TPI (10-18) with larger teeth for faster cutting and better chip clearance.

Q6: Should I use cutting fluid when cutting metal with a hacksaw?

A6: It’s highly recommended, especially for harder metals. Cutting fluid acts as a lubricant, reducing friction and heat. This keeps the blade sharper for longer, prevents it from overheating and dulling, and helps clear away metal chips for a cleaner cut.

Conclusion: Your Cutting Confidence, Boosted!

So, there you have it! The mystery of hacksaw blade teeth is solved. It’s not simply about “more” being better, but about choosing the right number of teeth per inch (TPI) for the material you’re cutting. Remember our genius tip: aim for at least two to three teeth in contact with the material at all times. This simple principle will ensure cleaner cuts, less effort, and longer blade life.

By understanding TPI, blade material, proper tension, and good cutting technique, you’re now equipped to tackle a wide range of cutting tasks with confidence. Whether you’re a homeowner fixing a leaky pipe, a hobbyist building a birdhouse, or a maker creating something new, the right hacksaw blade is your reliable partner. Don’t hesitate to experiment with different TPIs within the recommended ranges to see what works best for your specific projects. Happy cutting!