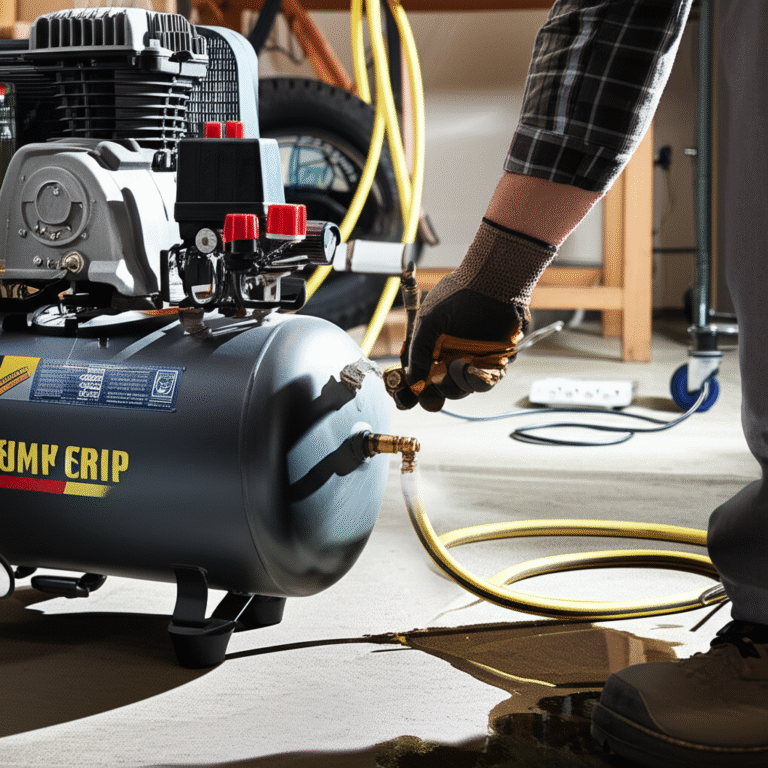

Don’t let water in your air compressor ruin your tools! Draining your air compressor water is simple, essential for tool longevity, and easily done with a few basic steps. This guide shows you the proven way to keep your compressor running smoothly and protect your investment.

Ever notice that little puddle of water after using your air compressor? It’s not just a nuisance; it’s a sign that moisture is building up inside your tank. This water can cause rust, damage your tools, and lead to costly repairs. Many first-time users worry about this, but the good news is that draining your air compressor is a straightforward process. With a little know-how, you can easily keep your compressor in top shape, ensuring it works reliably for all your projects, from inflating tires to powering your favorite nail gun. Let’s walk through the proven way to tackle this common issue and keep your air compressor happy and healthy.

Why Draining Your Air Compressor is Crucial

Think of your air compressor like a big metal tank. When the air inside cools down, any moisture in that air turns into liquid water. This happens naturally, especially in humid environments or when the compressor is working hard. If this water sits in the tank, it’s like leaving a steel bucket out in the rain – it starts to rust.

Rust flakes can get into your air lines, clog up your tools, and even cause them to fail prematurely. For sensitive tools like paint sprayers or intricate pneumatic tools, this can be a real problem. Water can also freeze in colder temperatures, potentially damaging the tank itself. Regularly draining this water is one of the simplest and most effective maintenance tasks you can perform to extend the life of your compressor and the tools you use with it.

Understanding the Drain Valve

Before we dive into the steps, let’s get acquainted with the key player: the drain valve. You’ll find this at the very bottom of your air compressor tank. It’s designed specifically for this purpose. There are a few common types:

- Manual Ball Valve: This is the most common type. It looks like a small handle you turn.

- Gate Valve: Similar to a faucet, you often have to lift and turn a handle.

- Petcock Valve: These are often smaller and might require a wrench to loosen.

Regardless of the type, its job is the same: to let out the collected water and any sediment. Knowing where it is and how it works is the first step to successful draining.

Tools You’ll Need

The beauty of draining your air compressor is that you don’t need a fancy toolkit. Here’s what you’ll likely need:

- A sturdy container or bucket to catch the water.

- A rag or shop towel for any drips.

- Possibly a wrench if your drain valve is a petcock type that requires one.

- Safety glasses – it’s always good practice to protect your eyes!

The Proven Step-by-Step Guide to Draining Air Compressor Water

Follow these simple steps to effectively drain the water from your air compressor. This method is safe, efficient, and will help protect your equipment.

Step 1: Ensure the Compressor is Off and Depressurized

Safety first! Never attempt to drain the tank while the compressor is running or still under pressure. This can cause a sudden, forceful expulsion of water and air, which could be dangerous.

- Turn off the power switch to your air compressor.

- Unplug the compressor from the power outlet.

- Open a connected air tool (like a blow gun or spray gun) or slightly open the regulator valve on the compressor itself. This will release any stored air pressure in the tank. You’ll know the pressure is released when you no longer hear air escaping.

Step 2: Position Your Container

Place your bucket or container directly underneath the drain valve. Make sure it’s stable and can hold a good amount of water. Some compressors can hold a surprising amount, especially after a long period of use or in humid conditions.

Step 3: Open the Drain Valve

Now for the main event! Slowly open the drain valve. If you have a ball valve, you’ll typically turn the handle 90 degrees. For a gate valve, lift and turn the handle. If it’s a petcock, you might need to use a wrench to loosen it slightly.

You should hear a hiss as the air escapes, followed by a stream of water. Don’t be alarmed if you see some sediment or rust particles mixed in – that’s normal and exactly what you want to get out.

Step 4: Let it Drain Completely

Allow the water to drain until only air is coming out, or until the flow stops completely. This might take a few minutes, depending on how much moisture has accumulated. For best results, let it drain for a minute or two even after the water stops, just to ensure all the moisture is expelled.

Step 5: Close the Drain Valve

Once you’re sure all the water is out, firmly close the drain valve. Make sure it’s snug to prevent any leaks. If you have a ball valve, turn the handle back to its original position. For other types, tighten it securely.

Step 6: Check for Leaks

Before you reconnect power or use the compressor, it’s a good idea to do a quick check. You can repressurize the tank slightly (by turning it on for a very short burst) and listen for any leaks around the drain valve. If you hear or see any, tighten the valve a bit more.

How Often Should You Drain Your Air Compressor?

The frequency of draining depends on a few factors, but here’s a general guideline:

- After Every Use: This is the golden rule for most users. It’s the easiest way to prevent moisture buildup.

- Humid Environments: If you live in a humid climate or use your compressor in a damp garage, you might need to drain it more frequently, possibly even mid-day if you’re using it for extended periods.

- Infrequent Use: If you only use your compressor occasionally, make sure to drain it before storing it for any length of time.

Think of it like checking your tire pressure – a little regular attention goes a long way!

Troubleshooting Common Issues

Sometimes, things don’t go exactly as planned. Here are a few common hiccups and how to handle them:

- Stuck Drain Valve: If the valve is difficult to turn, don’t force it too hard, as you could break it. Try applying a penetrating lubricant (like WD-40, but be sure to wipe it off thoroughly before use) and letting it sit for a few minutes. If it’s still stuck, you might need to replace the valve.

- Leaking Drain Valve: If the valve continues to leak after being tightened, the seal might be worn out. In this case, you’ll likely need to replace the drain valve. This is a relatively simple repair for most DIYers.

- No Water Comes Out: If you open the valve and nothing comes out, it could mean there’s no moisture buildup (great!) or the valve might be clogged with rust or debris. You can try gently tapping the valve with a wrench (if it’s a petcock type) or carefully probing the opening with a thin, non-metallic object to dislodge any blockage.

Automatic Drain Valves: A Convenient Alternative

For those who use their air compressors frequently or want to automate maintenance, automatic drain valves are a fantastic option. These devices are installed in place of the manual drain valve and use a timer or a moisture sensor to automatically release water at set intervals. This ensures your tank is always being drained, even if you forget.

While they require an initial investment, they can save you time and prevent potential damage from forgotten draining. You can find these at most hardware stores or online tool suppliers. Installation is usually straightforward, often just a matter of unscrewing the old valve and screwing in the new one.

When to Consider Professional Help

For most homeowners and DIYers, draining the air compressor is a task you can easily handle yourself. However, if you encounter any of the following, it might be time to consult a professional:

- You’re uncomfortable performing any of the steps.

- The drain valve is severely corroded or damaged and you can’t remove or replace it.

- You suspect internal damage to the tank or compressor components.

- You’ve tried basic troubleshooting and the problem persists.

A qualified technician can diagnose and fix more complex issues, ensuring your compressor is safe and functional.

Frequently Asked Questions (FAQ)

Q1: How often should I drain my air compressor?

It’s best practice to drain your air compressor after every use. If you live in a humid area or use it heavily, you might need to drain it more often. For infrequent users, draining it before storage is crucial.

Q2: What happens if I don’t drain the water from my air compressor?

Not draining the water can lead to rust forming inside the tank. This rust can flake off, travel through your air lines, damage your tools, clog them up, and reduce their lifespan. In freezing temperatures, water can also freeze and damage the tank.

Q3: Can I just let the air out of the tank to drain the water?

While releasing air pressure is a necessary first step, simply letting all the air out won’t necessarily drain all the water. You need to open the specific drain valve at the bottom of the tank to effectively remove the accumulated moisture.

Q4: My drain valve is stuck. What should I do?

If your drain valve is stuck, try applying a penetrating lubricant to the threads and letting it sit for a few minutes. If it’s still resistant, avoid forcing it too much to prevent damage. Gentle tapping might help. If it remains immovable, you may need to replace the valve.

Q5: What is the white, milky substance sometimes seen when draining?

This milky substance is often a mixture of water and oil. Small amounts of oil can get past the piston rings in the compressor and mix with the condensed water. While some oil is normal in oil-lubricated compressors, excessive amounts might indicate an issue needing professional attention.

Q6: Do electric compressors need draining?

Yes, absolutely. All air compressors, whether electric or gas-powered, compress air that contains moisture. This moisture will condense into water inside the tank as the air cools down, regardless of the power source.

Conclusion

Taking a few moments after each use to drain the water from your air compressor is one of the simplest yet most impactful maintenance tasks you can perform. It’s a proven way to prevent rust, protect your valuable air tools, and ensure your compressor performs reliably for years to come. By following these easy steps, you’re not just maintaining your equipment; you’re saving yourself potential headaches and costly repairs down the line. So, make it a habit, and enjoy the peace of mind that comes with a well-cared-for air compressor!