Keep water out of your air compressor with simple, effective methods like proper draining, using moisture separators, and ensuring a dry storage environment. These steps protect your equipment, ensuring it runs efficiently and lasts longer.

Nobody wants water messing with their air compressor. It’s a common frustration that can lead to rust, damaged tools, and costly repairs. But don’t worry! Keeping water out is totally doable, even if you’re new to air compressors. We’ll walk you through easy, proven ways to protect your investment. You’ll learn how to tackle this common issue step-by-step. Ready to keep your air compressor dry and happy?

Why Water is the Enemy of Your Air Compressor

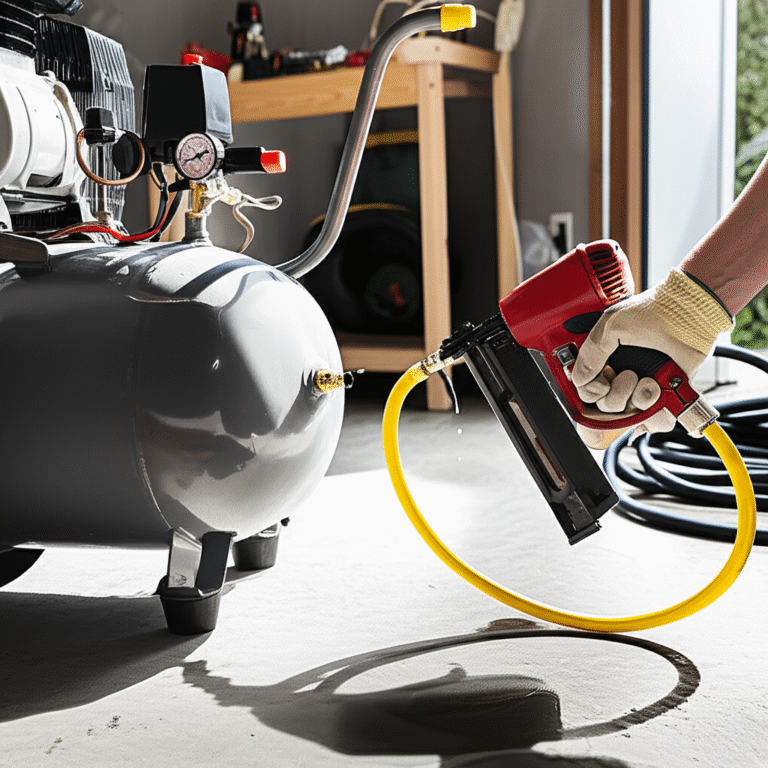

Think of water as the unwelcome guest at your air compressor’s party. When moisture from the air gets into your compressor, it can cause a whole host of problems. This moisture can condense inside the tank and the air lines, leading to rust. Rust particles can then travel through your air system, damaging sensitive tools like nail guns or paint sprayers. It can also clog filters and reduce the overall performance of your compressor. For anyone using an air compressor for DIY projects, car maintenance, or even winterizing, this is a big deal. Protecting your equipment means saving money and avoiding frustrating downtime.

Understanding How Water Gets In

So, how does this pesky water find its way into your otherwise reliable air compressor? It all starts with the air around us. Air naturally contains moisture, also known as humidity. When your air compressor sucks in this ambient air, it compresses it. As the air is compressed, its temperature rises, but then it cools down. When the air cools, the moisture it holds can turn into liquid water. This condensation collects in the compressor’s tank and air lines. The warmer and more humid the environment where you use or store your compressor, the more condensation you’re likely to encounter. It’s a natural process, but one we can actively manage.

Proven Ways to Keep Water Out

Fortunately, there are several straightforward and effective methods to combat moisture and keep water out of your air compressor system. These aren’t complicated or expensive fixes; they’re practical habits and simple additions that make a big difference.

1. Regular Draining of the Air Tank

This is the most crucial step, and it’s incredibly simple. Your air compressor tank has a drain valve, usually located at the very bottom. This is where all the condensed water collects. You need to open this valve regularly to let the water out.

How to Drain Your Tank:

- Safety First: Make sure the compressor is turned off and unplugged.

- Locate the Valve: Find the drain valve. It often looks like a small faucet or a petcock.

- Open Slowly: Place a small container or rag underneath the valve to catch any dripping water. Slowly open the valve. You might hear a hiss as the pressure releases.

- Let it Flow: Allow all the water to drain out. You’ll see water, and possibly some oily residue, come out.

- Close Tightly: Once the water has stopped draining, close the valve securely.

Frequency: Aim to drain your tank after every use, or at least daily if you use it frequently. If you live in a humid climate or use your compressor in a damp environment, you might need to drain it more often.

2. Install a Moisture Separator (Water Separator)

A moisture separator is a fantastic addition to your air compressor setup. It’s a device that attaches between your compressor’s outlet and your air hose. As the compressed air passes through it, it cools down, and the moisture condenses. The separator then collects this water, preventing it from reaching your tools.

Types of Moisture Separators:

- Manual Drains: These require you to manually open a valve to release the collected water, similar to the tank drain.

- Automatic Drains: These have a sensor that detects water and automatically releases it, offering more convenience.

Where to Install: The best place for a moisture separator is as close to the compressor’s outlet as possible. You can also install them at key points along your air lines or just before your tools.

3. Use an Air Dryer

For those who need extremely dry air, an air dryer is the ultimate solution. Air dryers are more sophisticated devices that actively remove moisture from the compressed air. There are a few types:

| Type of Air Dryer | How it Works | Best For |

|---|---|---|

| Refrigerated Dryers | Cool the compressed air to a low temperature, causing moisture to condense and be removed. | Continuous use, industrial applications, or where very dry air is critical. |

| Desiccant Dryers | Use a desiccant material (like silica gel) that absorbs moisture from the air. | Applications requiring extremely dry air (e.g., painting, sensitive electronics) or where refrigeration isn’t feasible. |

While air dryers are more of an investment, they provide the highest level of moisture removal and are essential for certain demanding applications. For most DIYers, a good moisture separator and regular draining will suffice.

4. Proper Storage Practices

Where you store your air compressor can also impact moisture levels. If your compressor is stored in a damp garage or shed, it’s more likely to accumulate condensation internally, even when not in use.

Storage Tips:

- Dry Environment: Store your compressor in the driest location possible. If your garage is often damp, consider using a dehumidifier.

- Elevate if Necessary: If your storage area is prone to puddles or flooding, keep the compressor elevated on a sturdy platform.

- Cover it Up: Use a breathable cover to protect the compressor from dust and debris, but avoid sealing it completely, which can trap moisture.

5. Maintain Your Air Filter

The air filter on your compressor is designed to keep dust and debris out of the intake. However, a clogged or damaged filter can reduce airflow and, in some cases, indirectly contribute to moisture issues by making the compressor work harder. Regularly check and clean or replace your air filter according to the manufacturer’s recommendations.

6. Consider an Oil-Lubricated vs. Oil-Free Compressor

This is more of a purchasing consideration, but it’s worth noting. Oil-lubricated compressors often produce a small amount of oil mist in the air line. While this can be beneficial for lubricating air tools, it can also mix with condensed water, creating a more stubborn sludge. Oil-free compressors don’t have this issue, but they can sometimes run hotter, potentially leading to more condensation if not managed properly. For most home users, the maintenance of draining is more important than the type of compressor.

7. Use an Air Hose Reel with a Built-in Drain

Some high-quality air hose reels come with a built-in drain valve. This allows you to drain the moisture that collects in the hose itself after use, preventing it from sitting there and potentially causing problems. If your current reel doesn’t have this feature, you might consider upgrading or simply ensuring you disconnect and drain the hose properly.

Tools You Might Need

To keep water out of your air compressor, you won’t need a huge toolkit. Here are a few basic items that will help:

- Adjustable Wrench or Pliers: For opening and closing stubborn drain valves or for installing moisture separators.

- Small Bucket or Container: To catch water when draining the tank.

- Rags or Shop Towels: For wiping up spills and keeping things clean.

- Thread Seal Tape (PTFE Tape): If you’re installing a new moisture separator or fittings, this helps create a watertight seal.

- Manual or Automatic Moisture Separator: A worthwhile investment for better protection.

Step-by-Step Guide: Draining Your Air Compressor Tank

Let’s break down the most important task – draining your tank – into simple, actionable steps. This is something you should do every time you finish using your compressor.

- Power Down and Unplug: First and foremost, turn off the power switch for your air compressor and unplug it from the wall outlet. This is a critical safety step.

- Locate the Drain Valve: Look at the bottom of your air compressor’s tank. You’ll find a valve there. It might look like a small faucet, a ball valve with a handle, or a petcock valve that you turn with a screwdriver or pliers.

- Position Your Container: Place a small bucket, pan, or a few shop towels directly underneath the drain valve. This will catch the water and any debris that comes out.

- Open the Valve:

- For Ball Valves: If it has a lever handle, rotate it 90 degrees so it’s perpendicular to the pipe.

- For Petcock Valves: If it has a small knob or wingnut, turn it counter-clockwise. You might need pliers if it’s tight.

You should hear a hiss as the air pressure inside the tank is released.

- Allow Water to Drain: Let the water drain out completely. You’ll see it coming out of the valve. Continue to let it drain until only air (or perhaps a little oil mist) comes out.

- Close the Valve: Once all the water is out, close the drain valve.

- For Ball Valves: Rotate the handle back parallel to the pipe.

- For Petcock Valves: Turn the knob or wingnut clockwise until it’s snug. Don’t overtighten.

- Clean Up: Wipe away any spilled water or oil with your rags.

- Inspect: Briefly check the drain valve to ensure it’s properly closed and not leaking.

Congratulations! You’ve successfully drained your air compressor tank. Making this a habit is the best way to prevent water damage.

The Importance of a Dry Compressed Air System

Keeping your compressed air system dry goes beyond just preventing rust in the tank. Dry air is essential for the longevity and performance of all the tools and equipment that use it. Think about it:

- Tool Longevity: Water can cause internal components of pneumatic tools (like nail guns, impact wrenches, or spray guns) to corrode and seize up. Dry air means your tools will last much longer.

- Paint Finish Quality: If you use your compressor for painting, water in the air lines can cause “fisheyes” or imperfections in the paint finish. Dry air ensures a smooth, professional result.

- Precision and Efficiency: Moisture can affect the performance of sensitive pneumatic equipment, leading to inconsistent operation and reduced efficiency.

- Winterizing: For tasks like winterizing irrigation systems, it’s crucial to blow out water with dry compressed air. If your air is moist, you might not fully remove the water, leaving it vulnerable to freezing.

According to the Engineering Toolbox, the dew point of compressed air can be significantly lower than the ambient air, meaning water will condense even in relatively cool conditions. Managing this condensation is key.

Troubleshooting Common Moisture Issues

Even with the best practices, you might encounter some moisture-related hiccups. Here’s how to address them:

Problem: Water still coming out after draining

Solution: This is normal. The first bit of air released will likely contain moisture. Keep draining until it’s mostly air. If you continue to get large amounts of water after every use, it might indicate very high humidity in your environment or a need for a more robust moisture removal system like a separator or dryer.

Problem: My tools are spitting water

Solution: This means water has accumulated in your air lines or tools. Drain your tank and air lines thoroughly. Consider installing a moisture separator closer to your tools or at the end of your main air line. Blow out the air lines with dry air before connecting your tools.

Problem: My compressor tank is rusty inside

Solution: If rust is already present, you may need to address it. For minor rust, draining and running the compressor for a short period can help dry it out. For significant rust, you might need to consult a professional or consider replacing the tank if it’s compromised. The best approach is prevention through regular draining.

Problem: My moisture separator is always full of water

Solution: This is actually a good sign that it’s working! Just make sure you are draining it regularly. If it’s an automatic drain and it’s not releasing water, the drain mechanism might be clogged or faulty and needs cleaning or replacement.

Frequently Asked Questions (FAQ)

Why is my air compressor tank wet inside?

This is due to condensation. As the compressor works and the air cools, moisture in the air turns into liquid water and collects in the tank. Regular draining is the solution.

How often should I drain my air compressor?

It’s best to drain your air compressor tank after every use. If you use it frequently, draining it daily is a good minimum. In humid conditions, more frequent draining may be necessary.

Can I use my air compressor in the rain?

It’s generally not recommended to operate an air compressor in heavy rain or extremely damp conditions. Moisture can be drawn into the compressor more easily, leading to increased condensation. If you must use it, ensure it’s protected from direct rain and drain the tank immediately afterward.

What happens if I don’t drain my air compressor?

If you don’t drain your air compressor, the accumulated water can cause the inside of the tank to rust. This rust can then travel through your air lines and damage your pneumatic tools, leading to costly repairs or replacements.

Are moisture separators worth the cost?

Yes, absolutely. For most users, a moisture separator is a very worthwhile investment. It significantly reduces the amount of water that reaches your tools, protecting them and improving the quality of your work, especially for tasks like painting.

Can I use regular compressed air for painting?

For best results in painting, it’s highly recommended to use dry, clean compressed air. Moisture or oil in the air can cause defects in the paint finish. Using a moisture separator and an air dryer will help ensure a professional finish.

Conclusion

Keeping water out of your air compressor isn’t a mystery; it’s a matter of consistent, simple maintenance. By making regular draining of the tank a habit, considering a moisture separator, and practicing good storage habits, you’re safeguarding your equipment. These steps will not only prevent rust and damage but also ensure your air compressor and the tools you power with it perform at their best for years to come. So, grab that wrench, open that valve, and give your compressor the dry, healthy environment it deserves. Happy compressing!