Don’t drain your air compressor’s water separator? You risk equipment damage, reduced efficiency, and potential safety hazards like rust, freezing, and contamination of your air tools. Regularly draining it is crucial for longevity and performance.

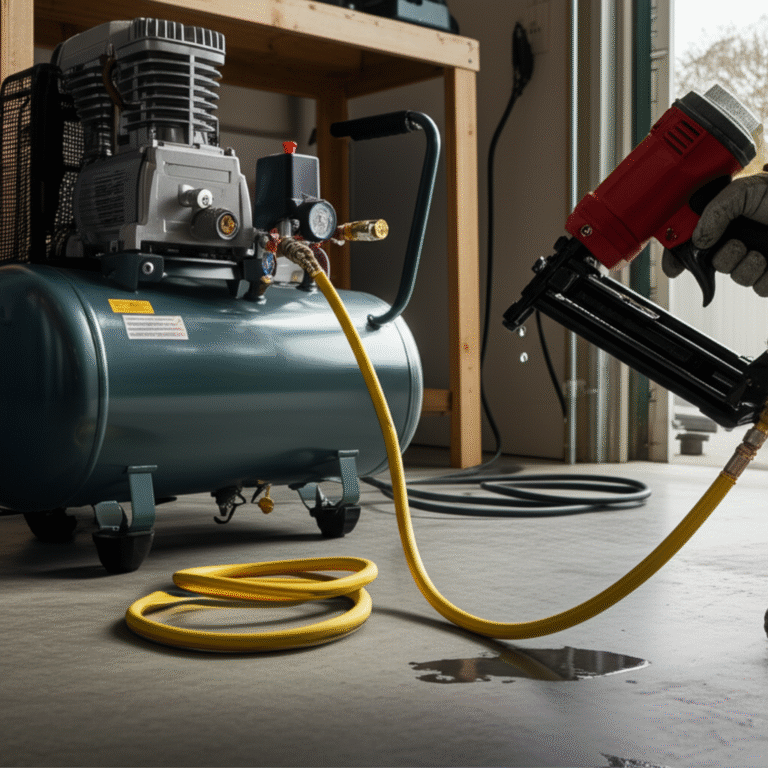

Hey there, fellow DIYers and homeowners! Ever looked at your air compressor and seen that little valve on the bottom of the water separator, wondering if it’s really that important? You’re not alone! Many of us get caught up in the excitement of a project, whether it’s inflating tires, running a nail gun, or getting that paint sprayer ready. But overlooking a simple maintenance step like draining the water separator can lead to some real headaches down the line. Don’t worry, though! I’m here to walk you through exactly what happens if you skip this crucial task and how easy it is to keep your compressor running smoothly. Let’s dive in!

The Unseen Enemy: Why Water Builds Up in Your Air Compressor

Air compressors work by compressing air. As air is compressed, its temperature rises. When this warm, compressed air cools down, it releases moisture. Think of it like the condensation you see on a cold glass of water on a hot day. This moisture, or water vapor, is then released from the air and collects in the tank and, importantly, in your water separator. The water separator is designed to catch this moisture before it can travel through your air lines and into your tools. It’s a vital component, but it needs a little help to do its job effectively.

This water buildup isn’t just a minor inconvenience; it’s an active threat to your equipment. Over time, even small amounts of water can cause significant problems. Understanding where this water comes from is the first step to preventing these issues.

What Happens If You Don’t Drain a Water Separator? The Essential Dangers

Skipping the drain on your water separator might seem harmless in the short term, but the consequences can be surprisingly severe. These issues can range from minor performance dips to costly equipment failures. Let’s break down the key dangers:

1. Rust and Corrosion: The Silent Saboteur

The inside of your air compressor tank and lines are typically made of metal. When water sits in these metal components, it creates a perfect environment for rust. Rust isn’t just unsightly; it weakens the metal over time. Small rust particles can break off and travel through your air system, potentially clogging filters or damaging the delicate internal parts of your air tools. Imagine a tiny piece of rust getting into the piston of your nail gun – it can cause it to seize up! This is especially true for the air tank itself, which can corrode from the inside out, eventually compromising its structural integrity.

2. Freezing and Expansion: A Winter Nightmare

If you live in a climate where temperatures drop below freezing, an undrained water separator can turn into a major problem. Water expands when it freezes. If your water separator is full of water and the temperature plummets, that water can freeze, expand, and potentially crack the separator itself or even damage the air tank. This can lead to leaks and costly repairs. It’s a common reason for compressor failure during colder months if not properly managed.

3. Contamination of Air Tools and Applications

The primary job of your air compressor is to provide clean, dry air. When water isn’t removed, it can travel through your air lines and into your tools. For many applications, this is unacceptable:

- Painting: Water in the air supply can cause paint to spray unevenly, create blisters, or leave a poor finish. It can ruin a paint job.

- Nail Guns/Staplers: Moisture can lead to internal corrosion, gumming up the mechanisms, and reducing the force of the piston, resulting in nails or staples not driving fully.

- Inflating Tires: While less critical, introducing moisture into tires isn’t ideal and can contribute to corrosion inside the tire rim over time.

- Pneumatic Tools in General: Any tool with moving parts, especially those with seals and O-rings, can be damaged by water. Lubrication can be washed away, leading to increased wear and premature failure.

4. Reduced Compressor Efficiency and Performance

Water in the system takes up space that should be filled with air. This means your compressor has to work harder to achieve the desired pressure. It can also lead to more frequent cycling of the motor, increasing wear and tear and consuming more electricity. You might notice your compressor takes longer to build pressure or doesn’t reach its full potential, impacting your productivity.

5. Filter and Regulator Damage

Many air compressor systems include inline filters and regulators to ensure air quality and control pressure. Water and rust particles carried through the system can quickly clog or damage these components. A clogged filter will restrict airflow, reducing efficiency. A damaged regulator might not maintain the correct pressure, leading to inconsistent tool performance or even over-pressurization, which is a safety hazard.

The Science Behind It: Why Water Separators Work (and Need Draining)

A water separator, often called a moisture trap or drain, is typically a simple device at the lowest point of your air system where water naturally collects. There are a few common types:

- Manual Drain Valves: These are usually small petcock-style valves or ball valves that you manually open to release the accumulated water.

- Automatic Drain Valves: These use a float mechanism or an electronic sensor to detect water and automatically open a valve to drain it. Even automatic ones can sometimes get clogged or fail, so periodic checks are still a good idea.

The principle is simple physics: water is denser than air and will settle to the lowest point. The separator’s job is to provide an easy way to remove it. However, if the water isn’t removed, it just keeps accumulating, and the problems described above begin to manifest.

How Often Should You Drain Your Water Separator?

The frequency of draining depends on several factors, including:

- Usage: The more you use your compressor, the more moisture it will generate.

- Humidity: Humid environments lead to more water condensation.

- Ambient Temperature: Temperature changes contribute to condensation.

As a general rule of thumb:

- After each use: This is the ideal practice for manual drain valves. It prevents water from sitting in the system overnight or for extended periods.

- Daily (if used frequently): If you’re using your compressor heavily throughout the day, draining it at the end of the day is a good habit.

- Weekly (for light use): If you only use your compressor occasionally, checking and draining it at least once a week is recommended.

Always consult your air compressor’s manual for specific recommendations from the manufacturer. They know their equipment best!

How to Drain Your Air Compressor Water Separator: A Simple Guide

Draining your water separator is usually a straightforward process. Here’s a step-by-step guide for the most common manual drain valve:

Tools You Might Need:

- A sturdy container or bucket to catch the water.

- Gloves (optional, for cleanliness).

- A rag or shop towel.

Steps:

- Ensure the Compressor is Off and Depressurized: Safety first! Turn off your air compressor and disconnect it from the power source. Release any pressure remaining in the tank by opening a connected air tool or a dedicated bleed valve. This prevents water from being forcefully expelled.

- Locate the Drain Valve: The drain valve is typically found at the very bottom of the air compressor tank. It often looks like a small spigot, a petcock, or a ball valve handle.

- Position Your Container: Place your bucket or container directly underneath the drain valve.

- Open the Drain Valve: Slowly open the valve. You’ll hear a hiss as any residual air escapes. Water will begin to flow out. For petcock-style valves, you might need to turn a small handle. For ball valves, you’ll turn the handle 90 degrees.

- Let it Drain: Allow all the water to drain out. You’ll see a stream of water, which may be cloudy or contain rust particles. Let it drain until only air is coming out.

- Close the Drain Valve: Once all the water is out, securely close the drain valve. Ensure it’s fully closed to prevent leaks.

- Clean Up: Wipe up any spilled water with your rag.

- Check for Leaks: If you’re comfortable, you can repressurize the tank slightly and check around the drain valve for any leaks.

For compressors with automatic drain valves, you’ll still want to periodically check that they are functioning correctly and not clogged. You can usually test them by manually actuating the drain mechanism (if available) or by listening for the periodic “hiss” of drainage.

Table: Common Air Compressor Problems and Their Relation to Water Buildup

Here’s a quick look at how neglecting your water separator can manifest as common air compressor issues:

| Problem Observed | Likely Cause Related to Undrained Water | Impact on Performance/Equipment |

|---|---|---|

| Rust particles in air lines | Internal tank corrosion due to standing water | Clogged filters, damaged tool components |

| Paint defects (blisters, poor finish) | Water in the air supply to the sprayer | Ruined paint jobs, wasted materials |

| Nail gun misfires or weak impact | Corrosion and gumming of internal tool parts | Reduced productivity, damaged tools |

| Compressor takes longer to build pressure | Reduced tank volume due to water, increased system load | Lower efficiency, increased energy consumption, motor strain |

| Air leaks from the tank bottom | Corrosion and weakening of the tank material, or cracked drain valve from freezing | Loss of pressure, potential safety hazard, costly tank replacement |

Maintaining Your Air System for Peak Performance

Beyond draining the water separator, a few other simple maintenance practices will keep your air compressor and tools in top shape:

- Check Air Filters: Regularly inspect and clean or replace the air intake filter. A clogged filter restricts airflow and strains the motor. You can find great resources on air filter maintenance from organizations like the Occupational Safety and Health Administration (OSHA), which emphasizes the importance of proper compressed air system maintenance for safety.

- Inspect Hoses and Fittings: Look for cracks, kinks, or leaks in your air hoses and fittings. Leaks waste air and reduce efficiency.

- Lubricate Tools (if applicable): If you have pneumatic tools that require oil lubrication, follow the manufacturer’s recommendations for oil type and frequency.

- Store Properly: If storing your compressor for an extended period, especially in freezing temperatures, ensure the tank and separator are completely drained.

These small steps, including the crucial habit of draining the water separator, contribute significantly to the lifespan and reliable operation of your entire compressed air system.

Frequently Asked Questions (FAQ)

Q1: Can water in the air compressor tank cause it to explode?

While extremely rare, severe internal corrosion from prolonged water exposure can weaken the tank’s metal structure. If a severely compromised tank were to over-pressurize without a functioning safety relief valve, the risk of catastrophic failure exists. However, regular draining and maintenance significantly mitigate this risk. Always ensure your compressor’s safety relief valve is functional.

Q2: My air compressor has an automatic drain valve. Do I still need to check it?

Yes, it’s a good idea to check automatic drain valves periodically. They can become clogged with rust or sediment, or the mechanism can fail. Listening for the occasional hiss of drainage or manually testing the valve (if your model allows) can confirm it’s working correctly.

Q3: What does the water coming out of the drain valve look like?

Typically, the water will appear cloudy and may contain small particles of rust or debris from inside the tank. If you see oily residue, it could indicate a problem with the compressor’s internal seals or lubrication system, which might require professional attention.

Q4: Is it okay to leave the drain valve slightly open all the time?

No, it is generally not recommended to leave the drain valve open all the time. This would cause your compressor to constantly lose air pressure, preventing it from building up to the required operating level. It also wastes energy as the compressor would run continuously trying to maintain pressure.

Q5: How much water can accumulate in an air compressor tank?

The amount of water can vary greatly depending on usage, humidity, and ambient temperature. On a humid day with moderate use, you might drain a few ounces to over a pint of water after a single session. Over weeks or months of neglect, the accumulation can be significant.

Q6: Can I use my air compressor for breathing air if I don’t drain the water separator?

Absolutely not. Breathing air requires extremely high purity. Water, rust, and oil contamination in the air supply can be hazardous to your health. Specialized breathing air filters and compressors are required for such applications, and meticulous maintenance, including proper water drainage, is paramount.

Conclusion: A Simple Habit for a Long-Lasting Compressor

As you can see, that little drain valve on your water separator is a surprisingly important part of your air compressor’s maintenance routine. What might seem like a minor oversight – not draining the water – can lead to a cascade of problems, from damaging rust and freezing issues to poor performance and costly repairs for your tools. By making it a habit to drain your water separator after each use, or at least regularly, you’re not just maintaining your compressor; you’re protecting your investment and ensuring it performs reliably for years to come.

It’s a simple, quick task that pays dividends in efficiency, longevity, and avoiding frustrating breakdowns. So, next time you finish a project, take those extra few moments. Give that valve a turn, let the water out, and breathe easy knowing your air compressor is in good health. Happy building, fixing, and creating!