Don’t drain your air compressor’s water separator? You risk rust, damage to tools, reduced performance, and potential safety hazards from contaminated air. Regularly draining prevents these issues, ensuring your compressor and connected equipment work reliably and safely.

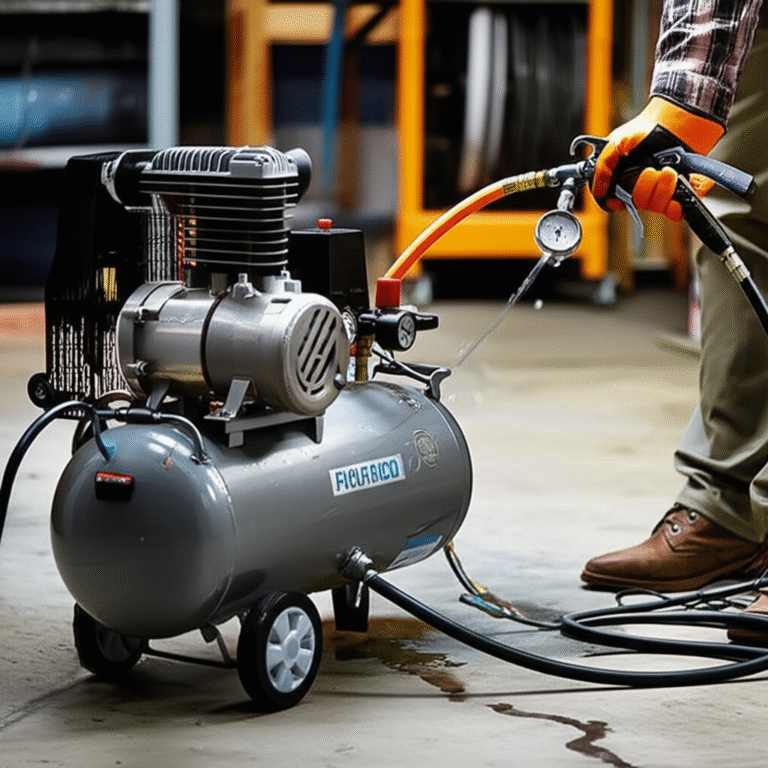

Hey there, fellow DIYers and tool enthusiasts! Samuel H. Murphy here from Capische. We all love the power and versatility of air compressors, whether we’re inflating tires, powering a nail gun, or getting our sprinkler systems ready for winter. But there’s one little maintenance step that many folks overlook, and it can lead to some surprisingly big headaches: not draining the water separator. It’s a common oversight, and honestly, it’s easy to forget when you’re busy with a project. But ignoring it can cause more trouble than you might think. Don’t worry, though! I’m here to walk you through exactly what can go wrong and why this simple task is so crucial for keeping your equipment running smoothly and safely. We’ll break down the dangers and show you why it’s worth those few extra seconds.

The Silent Killer: Why Water in Your Air System is a Problem

Think of your air compressor as the heart of your pneumatic tool setup. It pumps air, but that air isn’t perfectly dry. As the air is compressed, moisture naturally condenses out of it. This is completely normal! Your air compressor setup usually includes a water separator, often found right after the tank or at the tool connection, designed to catch this moisture. Its job is to prevent that water from getting into your valuable tools and air lines. However, if you don’t regularly drain the collected water from this separator, it can start to cause a cascade of problems.

This collected water isn’t just plain water; it can pick up oil and other contaminants from inside the compressor. When left to sit, it becomes a breeding ground for rust and corrosion. This sludge can then travel through your air lines, wreaking havoc on the delicate internal components of your air tools. It’s like letting dirt build up in your car’s engine – eventually, things are going to break down.

The Essential Dangers: What Happens If You Don’t Drain

So, what exactly happens if you skip that draining step? Let’s dive into the most common and critical issues:

1. Rust and Corrosion: The Slow Undermining

This is probably the most significant danger. Metal components inside your air compressor tank, the air lines, and especially your air tools are susceptible to rust when exposed to moisture. This rust doesn’t just make things look bad; it weakens the metal. In the air tank, rust particles can break off and travel through the system, acting like tiny bits of sandpaper. For your tools, this means:

- Reduced lifespan: Rust wears down internal parts faster.

- Internal damage: Pistons, valves, and seals can be scored and damaged.

- Blockages: Rust flakes can clog small air passages.

The air receiver tank, if not drained, can also rust from the inside out. Over time, this can compromise the structural integrity of the tank, which is a serious safety concern.

2. Tool Damage and Malfunction: Your Tools Suffer

Air tools, especially precision tools like nail guns, impact wrenches, and paint sprayers, have very fine internal mechanisms. Even a small amount of water can cause:

- Sticking parts: Moisture can cause plungers, pistons, and valves to stick or seize.

- Lubrication washout: Water can wash away the specialized lubricants that keep tools running smoothly.

- Corrosion of internal components: Small metal parts inside the tool can rust, leading to erratic performance or complete failure.

- Impact on air quality: For painting, water in the air can cause fisheyes or a poor finish.

Imagine your nail gun jamming constantly or your impact wrench losing its power. That’s often the direct result of water contamination from a neglected separator.

3. Reduced Airflow and Pressure: A Loss of Power

Water accumulating in the system, especially in the lines and at connection points, can create partial blockages. This restricts the flow of air, meaning your tools won’t receive the volume or pressure they need to operate efficiently. You might notice:

- Lower tool performance: Nail guns might not drive nails fully, or grinders might spin slower.

- Longer cycle times: The compressor might have to work harder and longer to build up pressure.

- Increased energy consumption: Your compressor will use more electricity trying to compensate for the reduced efficiency.

This inefficiency can lead to wasted energy and a frustrating user experience.

4. Freezing in Cold Weather: A Seasonal Hazard

This is a critical danger, especially if you use your compressor in colder climates or for tasks like winterizing irrigation systems. If water collects in the air lines or regulator and the temperature drops below freezing, that water will turn to ice. Ice:

- Can completely block air lines: Preventing any air from passing through.

- Can expand and damage components: Bursting hoses, cracking regulators, or damaging tool parts.

- Makes draining impossible: Until the temperature rises above freezing.

This can lead to costly repairs and leave you unable to use your equipment when you need it most. For those winterizing sprinkler systems, ice in the lines can cause significant damage if not properly cleared by dry air.

5. Contaminated Air Output: Affecting Your Work and Health

The water that collects isn’t pure. It can mix with oil and other particles from the compressor. When this contaminated water gets into your air supply, it can:

- Spoil paint finishes: Causing defects like “fisheyes” or poor adhesion.

- Contaminate food or beverages: If used in food-grade applications.

- Create health hazards: If inhaled, especially if the compressor is used in enclosed spaces or for tasks like sandblasting where fine particles are involved. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of clean, dry air for workplace safety.

Understanding Your Water Separator

Most air compressor systems have at least one point where water can collect and be drained. This is often:

- At the bottom of the air receiver tank: Many tanks have a drain valve.

- In inline water separators/filters: These are often placed near the compressor outlet or before the regulator.

- In regulators and air dryers: If your system includes these.

These separators typically have a small valve at the bottom. This valve can be a manual drain (a small knob or lever you turn) or an automatic drain (which opens periodically or when a certain amount of water is detected). Regardless of the type, they need to be checked and, if manual, operated regularly.

How Often Should You Drain?

The frequency of draining depends on a few factors:

- Usage: The more you use your compressor, the more moisture will condense.

- Humidity: Humid environments produce more condensation.

- Compressor type: Oil-lubricated compressors may produce more water mixed with oil than oil-free ones.

- Ambient temperature: Temperature fluctuations can increase condensation.

As a general rule of thumb:

- After each use: This is the best practice, especially if you’ve used the compressor for an extended period.

- Daily: If you use it frequently.

- Weekly: If usage is light, but still check for any visible water.

It’s always better to drain too often than not enough. A quick check can save you a lot of trouble.

Simple Steps to Prevent the Problems: Draining 101

Draining your water separator is a straightforward process. Here’s how to do it, covering both manual and automatic drains:

For Manual Drains:

Tools You Might Need:

- A small container or bucket to catch the water.

- Gloves (optional, as the discharge can be oily).

- A rag for wiping up spills.

Steps:

- Ensure the Compressor is Off and Depressurized: For safety, turn off the compressor and bleed off any remaining air pressure from the tank. You can do this by opening a connected tool or using the tank’s main drain valve slightly.

- Locate the Drain Valve: Find the small valve at the bottom of your air receiver tank or water separator bowl. It might look like a small knob, a lever, or a petcock.

- Position Your Container: Place your bucket or container directly beneath the drain valve.

- Open the Valve Slowly: Turn the valve slowly. You’ll hear air hissing out, and water (likely mixed with some oil and debris) will start to discharge into your container.

- Let it Drain: Allow the water to drain until only air comes out. This usually takes just a few seconds.

- Close the Valve: Once the water has drained, close the valve securely.

- Wipe Down: Use a rag to wipe away any drips or spills.

For Automatic Drains:

Automatic drains are designed to do the work for you, but they still need occasional checks:

- Check for Functionality: Periodically listen for the brief hiss of the drain releasing water. If you don’t hear it, the drain might be clogged or faulty.

- Manual Override (If Available): Some automatic drains have a manual override button. Pressing this should release any accumulated water. If it doesn’t, the drain needs cleaning or replacement.

- Clean the Drain: If you suspect a blockage, you may need to unscrew the automatic drain from the tank or separator bowl for cleaning. Consult your compressor’s manual for specific instructions.

Comparing Drain Types

Here’s a quick look at the pros and cons of different drain types:

| Drain Type | Pros | Cons |

|---|---|---|

| Manual Drain Valve | Simple, reliable, low cost, complete control over draining. | Requires user intervention, can be forgotten, may be inconvenient. |

| Automatic Timer Drain | Automated, consistent draining, reduces user error. | Requires power (solenoid type), can be set incorrectly (too frequent/infrequent), potential for failure. |

| Automatic Float Drain | Automated, no power required, drains only when water is present. | Can get stuck if debris is present, may not drain completely if float mechanism fails. |

Maintaining Your Air System for Longevity

Beyond draining, a few other simple practices will extend the life of your compressor and tools:

- Regular Filter Replacement: Air intake filters keep dust and debris out of the compressor.

- Oil Changes (for oil-lubricated models): Follow the manufacturer’s recommendations for oil type and change intervals.

- Inspect Hoses and Fittings: Check for leaks or damage regularly.

- Clean the Exterior: Dust buildup can cause overheating.

A well-maintained system is an efficient system. For more on general air compressor maintenance, resources like Popular Mechanics often offer practical advice.

Frequently Asked Questions (FAQs)

Q1: What happens if I don’t drain my air compressor tank?

If you don’t drain your air compressor tank, water will accumulate. This moisture can cause rust and corrosion inside the tank and air lines, leading to tool damage, reduced airflow, and potential tank weakening over time.

Q2: Can water damage my air tools?

Yes, absolutely. Water can wash away lubricants, cause internal parts to rust and seize, and lead to erratic performance or complete failure of air tools. For painting, it can ruin your finish.

Q3: How often should I drain the water separator on my air compressor?

It’s best practice to drain it after each use, or at least daily if you use it frequently. In very humid conditions or with heavy use, you might need to drain it more often.

Q4: What is the white milky substance that comes out when I drain?

This is typically a mixture of water, oil (from oil-lubricated compressors), and sometimes rust particles or other contaminants. It indicates that moisture has been present and is being flushed out.

Q5: My compressor has an automatic drain. Do I still need to check it?

Yes, it’s a good idea to check automatic drains periodically to ensure they are functioning correctly. Listen for them to cycle, and if they have a manual override, test it occasionally to make sure it’s not stuck.

Q6: What if I live in a cold climate and forget to drain?

If water freezes in your air lines or tools, it can expand and cause significant damage, such as bursting hoses or cracking components. It will also block airflow until it thaws.

Q7: Is it safe to use my compressor if the tank is rusty inside?

It’s generally not recommended. Internal rust can weaken the tank’s structure, posing a safety risk. Rust particles can also contaminate your air supply and damage your tools. It’s best to address internal rust promptly, which may involve cleaning or tank replacement.

Conclusion: A Small Task for Big Rewards

So, there you have it! Skipping the simple step of draining your air compressor’s water separator might seem insignificant, but the potential consequences are far-reaching and can be quite costly. From the slow, insidious creep of rust and corrosion to the immediate damage of your valuable air tools, the risks are real. Remember, that moisture is a natural byproduct of compression, and your water separator is there to manage it. By taking just a few moments after each use, or at least daily, to drain that collected water, you’re actively protecting your investment.

You’re ensuring your compressor runs efficiently, your tools perform at their best, and you avoid those frustrating breakdowns that can derail your projects. It’s a small habit that pays off immensely in the long run, keeping your air system reliable and your DIY adventures smooth sailing. So, next time you finish using your compressor, give that drain valve a quick turn – your tools will thank you for it!