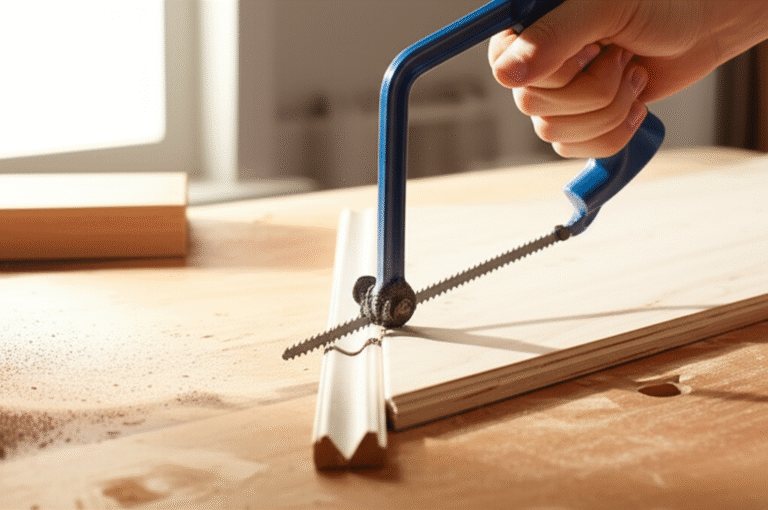

A coping saw is a versatile hand tool primarily used for intricate curved cuts, detailed patterns, and precise joinery in woodworking and other crafts. It excels at cutting curves, shapes, and removing waste material cleanly, making it ideal for tasks like cutting molding, creating decorative elements, and fitting joints.

Ever found yourself staring at a piece of wood, a tricky curve, or a detailed pattern, wondering if there’s a better way than wrestling with a big, clumsy saw? Many DIYers and woodworkers face this challenge. Trying to make those delicate cuts with the wrong tool can lead to frustration, wasted material, and less-than-perfect results. But what if I told you there’s a simple, elegant solution that’s been around for ages? The coping saw is that solution. It’s a surprisingly capable tool that, once you understand its quirks, can unlock a world of precision and creativity in your projects. We’ll walk through exactly what this handy saw is good for, how to use it effectively, and why it deserves a spot in your toolkit.

Understanding the Coping Saw: More Than Just a Saw

At its heart, a coping saw is a type of bow saw, characterized by its U-shaped frame and a very thin, fine-toothed blade held under tension. This design is what gives it its unique cutting capabilities. Unlike a handsaw with a rigid blade, the coping saw’s flexible blade and narrow kerf (the width of the cut) allow for incredibly tight turns and intricate shapes. Think of it as the scalpel of the sawing world – precise, controlled, and designed for detail work.

The name “coping saw” itself hints at one of its most common uses: cutting “copes” in molding. A cope is a type of joinery where the end of one piece of molding is cut to fit snugly against the profile of another, often used at inside corners in decorative trim work. This requires a very precise angled cut, which the coping saw handles with finesse.

But its utility extends far beyond just trim. Whether you’re a seasoned woodworker crafting a delicate inlay, a hobbyist creating a unique puzzle, or a homeowner tackling a DIY project, understanding the strengths of a coping saw will open up new possibilities.

What Is a Coping Saw Used For Cutting? The Core Applications

The versatility of a coping saw means it’s useful for a surprising range of tasks. Here are some of the most common and effective uses:

- Cutting Intricate Curves and Shapes: This is where the coping saw truly shines. Its thin blade can pivot and turn easily, allowing you to follow complex curves and cut out detailed shapes that would be impossible with a standard handsaw.

- Making Internal Cuts: Need to cut a shape or opening within a piece of material, rather than cutting from an edge? The coping saw is perfect for this. You can detach the blade from the frame, thread it through a pre-drilled hole in your material, reattach it, and then cut out the desired shape from the inside.

- Trimming and Fitting Moldings: As mentioned, cutting copes in trim is a classic use. It’s also excellent for making precise, clean cuts on decorative moldings, picture frames, and other architectural details where a clean finish is essential.

- Creating Dovetail Joints and Other Fine Joinery: While not its primary function, experienced woodworkers can use a coping saw for certain fine joinery tasks, like cutting the waste out of dovetail pins or other small, precise cuts.

- Cutting Thin Wood and Plywood: Coping saws work best on thinner materials. They are ideal for cutting through hardwoods and softwoods up to about 1 inch thick, as well as plywood and veneers.

- Working with Other Materials: Beyond wood, a coping saw with the right blade can also be used for cutting plastics, thin metal sheeting, and even foam board for craft projects.

- Removing Waste Material: In some joinery, you might need to carefully remove small sections of material. The coping saw’s control makes it suitable for this delicate waste removal.

Choosing the Right Blade: The Secret to Success

The blade is the business end of your coping saw, and selecting the right one is crucial for achieving clean, efficient cuts. Coping saw blades come in various tooth counts (TPI – teeth per inch) and blade widths, each suited for different materials and tasks.

Blade Tooth Count (TPI)

The TPI of a blade dictates how smooth or aggressive the cut will be.

- High TPI (e.g., 14-20 TPI): These blades have more teeth packed closely together. They produce a finer, smoother cut and are ideal for cutting hardwoods, thin materials, and for detailed work where a clean finish is paramount. They cut slower but offer more control.

- Low TPI (e.g., 10-14 TPI): These blades have fewer, larger teeth spaced further apart. They cut more aggressively and faster, making them suitable for softer woods, thicker materials, and general-purpose cutting where a perfectly smooth finish isn’t the top priority.

Blade Width

The width of the blade also affects its ability to turn. Narrower blades are better for tighter curves.

- Narrow Blades: Excellent for very tight turns and intricate patterns.

- Wider Blades: Better for straighter cuts or gentler curves.

Blade Material

Most coping saw blades are made of hardened steel. For cutting metal or plastic, you’ll want blades specifically designed for those materials, often with different tooth shapes and hardness.

Pro Tip: Always ensure the teeth of the blade are pointing away from the handle – towards the direction of the cut. This is standard for most saws.

How to Use a Coping Saw: A Step-by-Step Guide

Using a coping saw might seem a bit fiddly at first, but with a little practice, you’ll be making precise cuts with confidence. Here’s how to get started:

Step 1: Prepare Your Material and Saw

- Secure Your Workpiece: Clamp your material firmly to a workbench or sawhorse. Ensure the area where you’ll be cutting is well-supported and accessible.

- Attach the Blade: If your blade isn’t already attached, slide it into the grooves on the ends of the saw frame. The teeth should point away from the handle.

- Tension the Blade: Most coping saws have a mechanism (often a wingnut or lever) to tension the blade. Tighten it until the blade is taut, like a guitar string. A loose blade will wander and break easily. If you’re unsure, a quick search for your specific saw model can show you how to tension it. For example, many modern designs use a simple twist of the handle to tension the blade.

Step 2: Positioning and Starting the Cut

- Mark Your Cut Line: Clearly mark the line you want to cut on your workpiece. For intricate work, a pencil line is usually sufficient.

- Position the Saw: Place the blade on your cut line. For internal cuts, you’ll need to drill a small starter hole slightly larger than the blade’s width within the waste area. Detach the blade from one end of the frame, thread it through the hole, and reattach it to the frame.

- Start the Cut: Hold the saw handle firmly with one hand and use your other hand to guide the frame. Start with a gentle, short pull stroke to create a small notch. This helps guide the blade.

Step 3: Making the Cut

- Use Smooth Strokes: Once you have a small kerf started, use smooth, steady strokes. Let the saw do the work; don’t force it.

- Maintain Control: Keep the frame of the saw perpendicular to the surface of the material for straight cuts, or tilt it slightly to follow curves. Your guiding hand should be on the frame, not the blade.

- Follow the Line: For curves, turn the workpiece, not the saw, as much as possible. This allows for tighter turns and better control. Keep your eye on the line.

- Manage Blade Twisting: If the blade starts to twist, you’re either pushing too hard, turning too sharply, or the blade isn’t tensioned enough. Ease up, adjust your angle, or re-tension the blade.

- Finishing the Cut: As you approach the end of a cut, especially on internal cuts, support the waste piece to prevent it from breaking off unevenly.

Step 4: Detaching the Blade (for Internal Cuts)

- Once the cut is complete and you need to remove the saw from an internal opening, simply detach the blade from one end of the frame, pull it out through the opening, and then reattach it to the frame for storage.

Coping Saw vs. Other Saws: When to Reach for Which

It’s helpful to understand how a coping saw fits into your toolkit alongside other saws. Each has its strengths:

| Saw Type | Primary Use | Strengths | Weaknesses |

|---|---|---|---|

| Coping Saw | Intricate curves, internal cuts, fine joinery, trim work | Excellent maneuverability for tight curves, precise control, ability to make internal cuts | Slow for long, straight cuts; limited to thinner materials; blade can break if mishandled |

| Jigsaw | Curved cuts, shape cutting in wood, plastic, metal | Fast, powerful, good for thicker materials, powered | Less precise for very fine details, can chip edges, requires electricity |

| Handsaw (Crosscut/Rip) | Straight cuts, rough cutting, general purpose | Fast for straight cuts, no power needed, durable | Poor for curves, limited detail work, can be physically demanding |

| Scroll Saw | Very intricate curves, detailed patterns, fine woodworking | Extremely precise for detailed work, stationary tool for stability, powered | Requires a workbench, limited to smaller pieces, more expensive than a coping saw |

As you can see, the coping saw fills a specific niche for detailed, manual cutting that power tools sometimes struggle to match in terms of finesse and accessibility for small jobs.

Maintaining Your Coping Saw

Like any tool, a little care will keep your coping saw in good working order for years to come:

- Blade Storage: Keep spare blades in a protective case to prevent them from bending or dulling.

- Blade Tension: Always loosen the blade tension when you’re finished using the saw. Leaving it under tension can weaken the frame over time.

- Cleaning: Wipe down the frame and blade after use, especially if you’ve been working with resinous woods, to prevent buildup. A light application of oil on the metal parts can prevent rust.

- Blade Replacement: Replace blades as soon as they become dull or damaged. A dull blade requires more force, leading to fatigue and poor results.

When to Use a Coping Saw for Trim Work

Trim work is a prime area where the coping saw excels. For inside corners, cutting a “cope” is often preferred over a simple miter cut. Here’s why and how:

- The Cope vs. The Miter: A miter cut is a simple angled cut (usually 45 degrees) that butts two pieces of trim together. While effective for outside corners, inside corners can be tricky. Wood expands and contracts, and if the wall corner isn’t perfectly square, mitered trim pieces can open up, creating unsightly gaps.

- How a Cope Works: To cope an inside corner, you typically cut one piece of trim at a 45-degree angle (a miter cut) and then use the coping saw to carefully cut away the excess wood behind that angle, following the profile of the molding. This leaves a thin “feather edge” that fits precisely against the profile of the second piece of trim, which is usually cut square or at a slight angle to meet the first piece.

- Benefits of Coping: This method creates a much more forgiving and professional-looking joint, especially on older homes with less-than-perfectly square walls. It allows for slight movement of the wood without opening gaps.

- Getting the Angle Right: You’ll often use a miter box or a miter saw to make the initial 45-degree cut on the molding. Then, you’ll use your coping saw to carefully shave away the waste material, following the shape of the molding’s profile. A great resource for understanding trim joinery can be found on sites like This Old House, which offers detailed guides.

Troubleshooting Common Coping Saw Issues

Even with the best intentions, you might run into a few snags. Here’s how to address them:

- Blade Breaking: This is usually due to insufficient blade tension, making a cut that’s too sharp for the blade’s width, or pushing too hard. Ensure the blade is taut and try to make your turns as gradual as possible.

- Blade Wandering: If the blade isn’t cutting straight, it might be dull, not tensioned enough, or you’re not holding the saw correctly. Check your blade’s sharpness and tension, and try to keep the saw frame stable.

- Rough Cuts: A rough cut often indicates a dull blade or using a blade with too few TPI for the material. Switch to a sharper blade with a higher TPI for a smoother finish.

- Difficulty Cutting: If you’re struggling to make progress, ensure you have the correct blade for the material and that it’s sharp. Also, check that you’re using the correct cutting stroke (usually pull strokes).

Frequently Asked Questions about Coping Saws

Q1: What is the main purpose of a coping saw?

A1: The main purpose of a coping saw is to cut intricate curves, shapes, and perform detailed joinery, especially in woodworking and trim installation.

Q2: Can I use a coping saw for straight cuts?

A2: While technically possible, a coping saw is not designed for long, straight cuts. Its thin, flexible blade is prone to wandering, and it’s much slower than a handsaw. It’s best reserved for curves and detailed work.

Q3: What kind of wood can I cut with a coping saw?

A3: You can cut most types of wood with a coping saw, including hardwoods and softwoods, as long as they are relatively thin (typically up to 1 inch thick). For thicker wood, you’ll need a different saw.

Q4: How do I make an internal cut with a coping saw?

A4: To make an internal cut, drill a small starter hole within the waste area of your material. Detach the blade from one end of the coping saw frame, thread it through the hole, reattach it, and then saw your desired shape. Once done, detach the blade to remove the saw.

Q5: How do I choose the right blade for my coping saw?

A5: For smooth, detailed cuts in hardwoods or thin materials, use a blade with a higher TPI (14-20). For faster cuts in softer woods or thicker materials, a lower TPI blade (10-14) is suitable. Narrower blades are best for tighter curves.

Q6: Is a coping saw difficult to use for beginners?

A6: While it requires a bit of practice to master, a coping saw is generally manageable for beginners. The key is to use light, steady strokes, keep the blade tensioned correctly, and support your workpiece properly. Start with simpler curves to build confidence.

Q7: Can a coping saw cut metal?

A7: Yes, with the correct blade. You’ll need to use a metal-cutting blade, which has a higher TPI and a different tooth geometry than wood-cutting blades. Always ensure the material is securely clamped and use appropriate safety gear.

Conclusion: Your Go-To for Detail Work

The coping saw is a fantastic tool for anyone who enjoys detailed work, whether you’re a seasoned woodworker or just starting out on your DIY journey. Its ability to navigate tight curves and make precise internal cuts makes it indispensable for tasks ranging from intricate scrollwork and puzzle making to the essential job of fitting trim in your home. By understanding its purpose, choosing the right blade,