Chainsaws and power saws are distinct tools with different purposes. A chainsaw is a portable, engine-driven saw with a cutting chain that rotates around a blade, ideal for felling trees and cutting large logs. A power saw is a broad category encompassing many electric or battery-powered cutting tools like circular saws, miter saws, and jigsaws, used for various DIY and woodworking tasks. Understanding their specific functions ensures you choose the right tool for your job.

Hey there, DIY enthusiasts and aspiring woodworkers! Ever stood in the tool aisle, scratching your head, wondering about the real differences between a chainsaw and, well, all those other power saws? It’s a common question, and honestly, it’s easy to get a little mixed up. These tools can look similar from a distance, but they’re built for very different jobs. Using the wrong one can lead to frustration, less-than-perfect cuts, and even safety hazards. Don’t worry, though! We’re going to break down exactly what makes a chainsaw a chainsaw and what sets other power saws apart. By the end of this, you’ll feel confident choosing the right tool for your next project, whether it’s trimming branches, building a deck, or crafting a beautiful piece of furniture. Let’s get cutting!

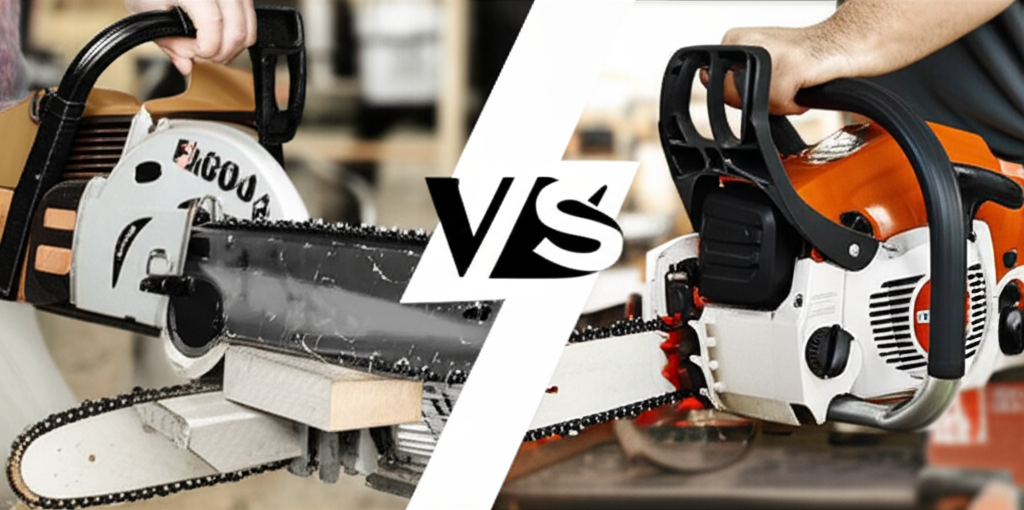

Understanding the Core Differences: Chainsaw vs. Power Saw

When we talk about “power saws,” it’s a really broad term. Think of it like saying “vehicles” – it could mean a car, a truck, a motorcycle, or even a bus! Similarly, “power saw” refers to any saw that uses electricity (either from a cord or a battery) or an engine to do the cutting. A chainsaw, on the other hand, is a very specific type of power saw.

The fundamental difference lies in their design and primary function. A chainsaw is built for aggressive, high-speed cutting of wood, especially larger pieces like trees and thick branches. Other power saws are generally designed for more controlled, precise cuts on lumber, plywood, and other building materials.

What Exactly is a Chainsaw?

A chainsaw is a portable, mechanical saw that features a set of teeth attached to a rotating chain. This chain moves at high speed around a guide bar. The engine (either gasoline or electric) powers the rotation of this chain, allowing it to efficiently cut through wood.

Key characteristics of a chainsaw:

- Cutting Mechanism: A continuous loop of metal chain with sharp teeth that moves rapidly around a guide bar.

- Power Source: Typically gasoline-powered for maximum power and portability, but increasingly available in powerful battery-operated and corded electric models.

- Primary Use: Felling trees, limbing (removing branches from a felled tree), cutting firewood, and clearing brush.

- Portability: Designed to be held and maneuvered by an operator, though they can be heavy.

- Safety Concerns: High risk of kickback, requiring significant safety gear and training.

What Falls Under the “Power Saw” Umbrella?

The term “power saw” is an umbrella category for a wide array of cutting tools that use power to operate. These tools are designed for a vast range of applications, from intricate woodworking to framing houses.

Here are some common types of power saws:

- Circular Saws: These are perhaps the most common power saws for DIYers. They use a circular, toothed blade that spins rapidly to make straight cuts through lumber, plywood, and other materials. They are versatile for ripping (cutting along the grain) and cross-cutting (cutting across the grain).

- Miter Saws (Chop Saws): Designed for making precise angled cuts, especially crosscuts. They have a blade that drops down onto the workpiece, which is held against a fence. Essential for framing, trim work, and creating accurate joints.

- Jigsaw (Saber Saw): Features a reciprocating blade that moves up and down. Excellent for making curved cuts, intricate shapes, and cutouts in various materials, including wood, metal, and plastic.

- Reciprocating Saws: Similar to jigsaws in their back-and-forth motion, but with a more robust blade and heavier build. They are often used for demolition, cutting through nails, pipes, and rough-sawn lumber.

- Table Saws: A stationary saw with a circular blade that protrudes through a table. They are used for precise rip cuts and crosscuts, offering excellent control and accuracy, especially for larger sheet goods and lumber.

- Band Saws: Use a continuous metal band with teeth that runs around two or more wheels. They are ideal for cutting curves, resawing (cutting thick lumber into thinner pieces), and making intricate shapes.

- Scroll Saws: A smaller, stationary saw with a very fine, reciprocating blade. They are perfect for extremely detailed scrollwork and fine woodworking projects.

As you can see, the variety within the “power saw” category is immense, each designed for specific tasks that require different types of cuts and levels of precision.

Chainsaw vs. Power Saw: A Feature Comparison

To really highlight the differences, let’s look at how these tools stack up against each other in key areas. This will help you visualize where each type of saw excels.

| Feature | Chainsaw | Common Power Saws (e.g., Circular Saw, Miter Saw) |

|---|---|---|

| Cutting Mechanism | Rotating chain with sharp teeth around a guide bar. | Spinning circular blade, reciprocating blade, or band blade. |

| Primary Function | Aggressive cutting of trees, logs, and thick branches. | Precise cuts in lumber, plywood, and building materials. |

| Portability | Handheld, designed for maneuverability in outdoor environments. | Varies; some are handheld (circular, jigsaw), others stationary (table, miter). |

| Precision & Control | Lower precision, designed for speed and power. | Higher precision and control, ideal for detailed work and joinery. |

| Power Source | Gasoline, battery, or electric. | Primarily electric (corded or battery). |

| Typical Materials Cut | Wood (logs, branches). | Wood, engineered wood, plastics, metal (with appropriate blades). |

| Safety Considerations | High risk of kickback, requires extensive PPE and training. | Varies by saw type, but generally lower kickback risk than chainsaws; still requires appropriate PPE. |

| Operator Skill Level | Requires significant training and experience due to power and safety risks. | Beginner-friendly options available, with increasing complexity for advanced saws. |

When to Choose a Chainsaw

A chainsaw is your go-to tool when you need to tackle tasks involving larger, natural wood. Think of it as the heavy-duty workhorse for anything related to trees and substantial logs.

- Felling Trees: If you need to cut down a tree, a chainsaw is the only tool for the job. Its power and design allow for efficient cutting through thick trunks.

- Cutting Firewood: Turning large logs into manageable pieces for your fireplace or wood stove is a classic chainsaw task.

- Limbing: Removing branches from fallen trees or standing trees (with proper safety and training) is best done with a chainsaw.

- Clearing Large Brush: For overgrown areas with thick, woody stems, a chainsaw can make quick work of it.

- Wood Sculpting/Carving: While requiring specialized bars and techniques, some artists use chainsaws for large-scale wood sculpting.

It’s important to remember that chainsaws are powerful and can be dangerous if not handled correctly. Always wear appropriate personal protective equipment (PPE) and understand safe operating procedures. The Occupational Safety and Health Administration (OSHA) provides extensive guidelines on chainsaw safety, which are crucial for anyone using this tool.

When to Choose Other Power Saws

For most home improvement, DIY projects, and woodworking, you’ll be reaching for one of the many other types of power saws. These tools offer the precision and control needed for building, crafting, and making accurate cuts in manufactured lumber and sheet goods.

- Building Decks or Fences: A circular saw is excellent for cutting deck boards and fence pickets to length.

- Framing a House: Circular saws and miter saws are essential for cutting studs, joists, and other framing members accurately.

- Installing Trim or Molding: A miter saw is invaluable for making clean, angled cuts for baseboards, crown molding, and window casings.

- Making Custom Furniture: Table saws, band saws, and even jigsaws are used for precise cuts, joinery, and shaping wood for furniture projects.

- Cutting Plywood or Sheet Goods: Circular saws (often with a guide) or table saws are best for breaking down large sheets of plywood or MDF.

- Making Curved Cuts or Cutouts: A jigsaw is the perfect tool for intricate shapes, sink cutouts in countertops, or decorative elements.

- Demolition Work: A reciprocating saw is ideal for cutting through walls, pipes, and other materials during tear-down projects.

The key here is the level of control and accuracy. If your project involves precise measurements, clean edges, and joining pieces together, you’ll want a power saw other than a chainsaw.

Safety First: Chainsaw vs. Power Saw Precautions

Safety is paramount with any power tool, but the risks and precautions can differ significantly between chainsaws and other power saws.

Chainsaw Safety Essentials

Chainsaws are inherently more dangerous due to their design and the nature of their work. The high-speed chain and the potential for kickback demand respect and rigorous safety practices.

- Personal Protective Equipment (PPE): This is non-negotiable. You absolutely need:

- Chainsaw Chaps: Special protective legwear designed to stop a moving chain.

- Helmet with Face Shield and Hearing Protection: Protects your head, eyes, and ears from debris and noise.

- Heavy-Duty Gloves: Provide grip and some protection.

- Steel-Toed Boots: Protect your feet from falling objects or accidental contact with the chain.

- Kickback: This is the most common and dangerous hazard. It occurs when the tip of the guide bar (the “kickback zone”) contacts an object, causing the saw to be thrown upward and backward violently. Always be aware of the bar tip and avoid cutting with it.

- Proper Stance and Grip: Maintain a firm, balanced stance with your feet apart. Grip the saw firmly with both hands, thumbs wrapped around the handles.

- Chain Tension: Ensure the chain is properly tensioned. A loose chain can derail; a too-tight chain can cause excessive wear.

- Sharp Chain: A sharp chain cuts more efficiently and safely. A dull chain requires more force, increasing the risk of kickback and operator fatigue.

- Safe Starting Procedures: Always start the saw on the ground or a stable surface, ensuring the chain is clear of obstructions.

- Never Work Alone: Always have someone nearby in case of an emergency.

For a comprehensive guide on safe chainsaw operation, resources like those from the U.S. Forest Service are invaluable.

General Power Saw Safety

While generally less prone to the extreme dangers of chainsaws, other power saws still require careful attention to safety.

- Read the Manual: Every power saw is different. Always read and understand your specific tool’s operation and safety features.

- Wear Safety Glasses: Essential for protecting your eyes from flying sawdust and debris, regardless of the saw type.

- Appropriate Clothing: Avoid loose clothing, jewelry, or anything that could get caught in the blade.

- Secure Your Workpiece: Use clamps or a vise to hold your material firmly in place. Never try to hold a small piece by hand while cutting.

- Blade Awareness: Always be aware of the blade’s position and never reach under the material being cut.

- Kickback (for Circular/Table Saws): While less severe than chainsaw kickback, it can still happen with circular and table saws if the blade binds in the wood. Ensure you’re using the right blade for the material and that the workpiece is supported correctly.

- Dust Collection: Many power saws generate fine dust that can be harmful to inhale. Consider using dust collection systems or wearing a dust mask.

- Cord Management: For corded tools, ensure cords are routed safely away from the cutting area and don’t create a tripping hazard.

Understanding the specific safety features and potential hazards of each type of power saw is crucial for a safe and productive experience.

Choosing the Right Tool for Your Project

The biggest takeaway is that there’s no “better” saw; there’s only the right saw for the job. Making the correct choice saves you time, effort, and ensures a better outcome.

When You Absolutely Need a Chainsaw:

- You’re cutting down a tree.

- You need to process large logs into firewood.

- You’re clearing thick, woody brush or fallen limbs.

- You’re doing large-scale outdoor wood removal.

When Other Power Saws Are the Better Choice:

- You need to cut lumber for framing, decks, or furniture.

- You require precise angled or straight cuts for joinery or trim.

- You need to make curved cuts or cut out shapes.

- You’re working with sheet goods like plywood or MDF.

- You’re doing indoor construction or renovation projects.

If you’re a beginner tackling your first home improvement project, starting with a circular saw or a jigsaw is generally more manageable and less intimidating than a chainsaw. As you gain experience, you can explore more specialized saws like miter saws or table saws for increased precision.

Maintaining Your Saws for Optimal Performance

Regardless of the type of saw you own, proper maintenance is key to its longevity, performance, and safety.

Chainsaw Maintenance

A well-maintained chainsaw is a safer and more efficient chainsaw.

- Chain Sharpening: This is the most critical maintenance task. A sharp chain cuts cleanly and reduces strain on the saw and operator. You’ll need a file guide and the correct size file for your chain. Regularly check the chain for dullness (it will produce sawdust rather than fine chips) and sharpen it often.

- Chain Tension: Check and adjust chain tension before each use and periodically during extended use.

- Lubrication: Ensure the chain oiler is functioning correctly and the reservoir is full. The chain needs constant lubrication to prevent wear and overheating.

- Air Filter: Clean or replace the air filter regularly, especially if you’re working in dusty conditions.

- Spark Plug: For gas-powered chainsaws, check and clean or replace the spark plug as needed.

- Bar Maintenance: Keep the guide bar clean and check for wear. You can file down burrs on the edges.

For detailed sharpening instructions, many manufacturers provide excellent video tutorials, and resources like Wood Magazine offer step-by-step guides.

General Power Saw Maintenance

Maintenance for other power saws focuses on keeping the cutting mechanism and the tool itself in good working order.

- Blade Care: Keep blades clean and sharp. For circular saws and miter saws, replace blades when they become dull or damaged. Different tasks require different blade types (e.g., fine-tooth for trim, aggressive for framing).

- Blade Guard Functionality: Ensure all blade guards are present, clean, and functioning correctly. For saws with retractable guards, make sure they spring back into place smoothly.

- Motor Vents: Keep the motor vents clear of dust and debris to prevent overheating. Use compressed air to blow out dust.

- Cord Inspection: For corded tools, regularly inspect the power cord for any cuts, frays, or damage.

- Battery Maintenance: For cordless tools, follow the manufacturer’s instructions for battery care to maximize their lifespan.

- Lubrication (for stationary saws): Some moving parts on table saws or miter saws may require occasional lubrication according to the manual.

Proper maintenance not only ensures your tools work efficiently but also significantly contributes to your safety.

Frequently Asked Questions (FAQ)

Q1: Can I use a chainsaw for DIY home projects like building a shelf?

A1: No, a chainsaw is not suitable for fine woodworking or DIY home projects like building a shelf. Its design is for aggressive cutting of logs and trees, and it lacks the precision needed for accurate joinery or detailed cuts. You would be much better off using a circular saw, miter saw, or even a handsaw for such tasks.

Q2: What is the biggest difference in safety between a chainsaw and a circular saw?

A2: The biggest difference in safety is the high risk of severe kickback with a chainsaw. While circular saws can also experience kickback, chainsaw kickback is far more violent and dangerous due to the rotating chain and bar design. Chainsaws also require more extensive PPE specifically designed to protect against the moving chain.

Q3: Which saw is better for cutting firewood: a chainsaw or a reciprocating saw?

A3: A chainsaw is significantly better for cutting firewood. Reciprocating saws are designed for demolition and cutting through smaller materials or branches, not for efficiently processing large logs. A chainsaw’s power and cutting chain are specifically made for this purpose.

Q4: Do I need a special license to own or operate a chainsaw?

A4: In most places, you do not need a special license to own a chainsaw. However, operating a chainsaw, especially for commercial purposes or on certain properties, may require training or certification. For personal use, the focus is on understanding safe operating procedures and using appropriate safety gear.

Q5: How often should I sharpen my chainsaw chain?

A5: You should sharpen your chainsaw chain whenever it starts to feel dull, typically after about 5-10 minutes of continuous cutting, or if it begins producing sawdust instead of fine wood chips. It’s also a good idea to sharpen it if you hit dirt or a rock, as this can quickly dull the chain.

Q6: Can I use the same blade for cutting hardwood and softwood with a circular saw?

A6: While you can use the same blade, it’s not ideal. Hardwood is denser and requires a blade with more teeth and a sharper angle for a cleaner cut. Softwood can be cut with fewer teeth. Using the wrong blade can result in rougher cuts, increased strain on the saw, and faster blade dulling.

Conclusion

So, there you have it! The world of power saws is diverse, and understanding the specific roles of each tool is key to success in your DIY and woodworking endeavors. A chainsaw is a powerful, specialized tool for aggressive wood cutting, primarily outdoors, dealing with trees and logs. On the other hand, the broad category of “power saws” encompasses a wide range of tools like circular saws, miter saws, and jigsaws, all designed for more controlled, precise cutting of lumber and building materials, often in more refined settings.

Remember, the right tool makes all the difference. Whether you’re tackling a backyard tree-trimming job or building a new bookshelf, choosing the correct saw ensures efficiency, accuracy, and, most importantly, safety. Always prioritize safety by wearing the right protective gear and understanding your tool’s operation. With the knowledge gained here, you’re well-equipped to select the perfect saw for your next project and approach it with confidence. Happy cutting!