To use a #10 machine screw, you need a specific drill bit size. Typically, a 5/32-inch drill bit works best for a #10 machine screw.

But, why is this important? Choosing the right drill bit size is crucial for a secure and snug fit. Using the wrong size can lead to loose or tight screw fittings, both of which can cause problems. A proper fit ensures the screw holds firmly without damaging the material.

In this guide, you’ll learn why the 5/32-inch drill bit is ideal for a #10 machine screw. We’ll also explore the importance of matching screws and drill bits for different materials. Understanding these basics helps you achieve better results in your DIY projects. Ready to get started? Let’s dive in!

Understanding Drill Bit Sizes

Choosing the right drill bit size is crucial for any project. This is especially true for using a #10 machine screw. The drill bit size needs to be precise to ensure the screw fits properly. A too-large hole can make the screw loose. A too-small hole can make it difficult to drive the screw in.

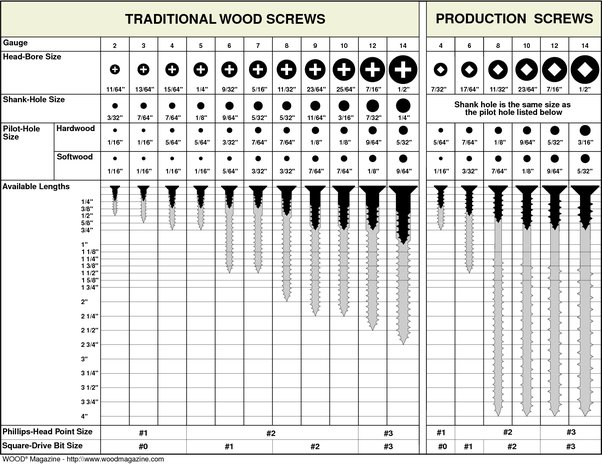

Drill Bit Size Charts

Drill bit sizes are available in various standards. These include fractional inches, letters, and metric measurements. Using a drill bit size chart can help you find the right bit for your screw. Below is a simple chart for common sizes:

| Screw Size | Drill Bit Size (Fractional Inches) | Drill Bit Size (Metric) |

|---|---|---|

| #10 | 5/32″ | 4mm |

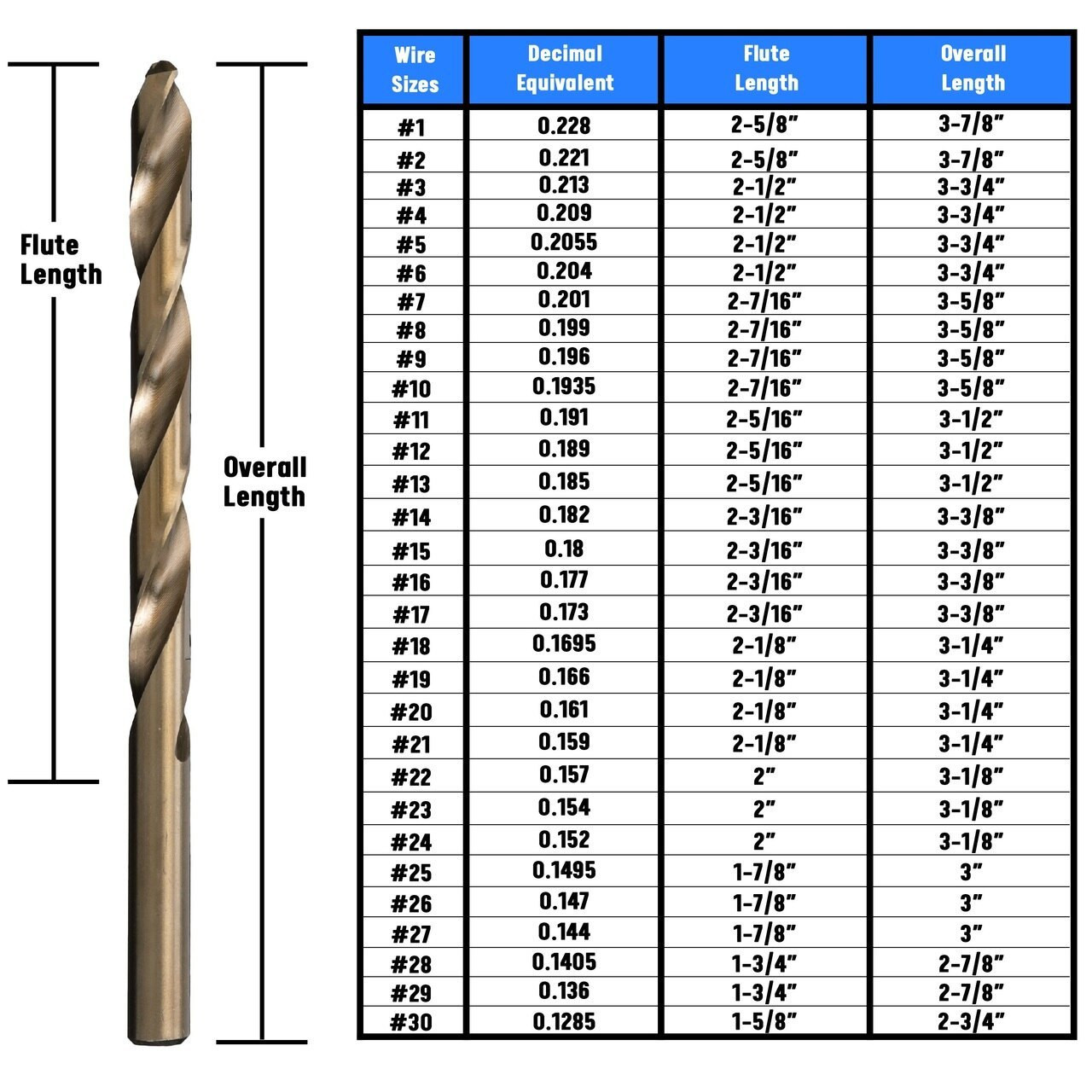

Decimal Equivalents

Understanding decimal equivalents of drill bit sizes can be useful. This is especially true when you do not have a size chart handy. Below is a list of decimal equivalents for common sizes:

- 5/32″ = 0.15625 inches

- 4mm = 0.15748 inches

As seen above, the difference between 5/32″ and 4mm is small. But, it can impact the fit of your screw. Always double-check your measurements.

Choosing the right drill bit size ensures your #10 machine screw fits securely. This prevents potential damage and ensures a strong hold.

Credit: diy.stackexchange.com

The #10 Machine Screw

The #10 machine screw is a popular choice in many projects. Its strength and durability make it suitable for various applications. The size and specifications are crucial for ensuring a perfect fit.

Common Uses

The #10 machine screw is used in both home and industrial projects. It is common in:

- Electronics assembly

- Metalworking

- Woodworking

- Automotive repair

Its versatility makes it a favorite among DIY enthusiasts and professionals.

Specifications

Understanding the specifications of the #10 machine screw is essential. Here is a table outlining the key details:

| Specification | Details |

|---|---|

| Diameter | 0.19 inches (4.83 mm) |

| Thread Count | 32 threads per inch |

| Thread Type | Unified National Coarse (UNC) |

| Length | Varies based on application |

The diameter is crucial for determining the drill bit size. A good fit ensures the screw holds firmly. Always refer to the thread count and type to match the screw with the right drill bit.

By knowing these specifications, you can select the correct drill bit size for your #10 machine screw. This ensures a secure and efficient installation.

Choosing The Right Drill Bit For #10 Screw

Choosing the right drill bit for a #10 machine screw is crucial. It ensures a secure fit and prevents damage. Knowing the correct size can save you time and frustration. Here’s a guide to help you select the perfect drill bit.

Recommended Drill Bit Sizes

To match a #10 machine screw, the drill bit size typically ranges between 3/16 inch and 13/64 inch. Here’s a quick reference table:

| Drill Bit Size (Fractional) | Drill Bit Size (Decimal) |

|---|---|

| 3/16 inch | 0.1875 inches |

| 13/64 inch | 0.2031 inches |

Factors To Consider

- Material Type: Different materials require different drill bit sizes. Softer materials might need a smaller bit.

- Thread Type: Coarse threads may need a different size than fine threads.

- Hole Depth: Deeper holes might need a slightly larger bit for easier screw entry.

Always double-check the manufacturer’s recommendations. This ensures the best fit and longevity for your screws.

Remember, using the right drill bit size prevents stripping and ensures a secure hold. Happy drilling!

Credit: drillsandcutters.com

Drilling Techniques

Choosing the right drill bit for a #10 machine screw is crucial. It ensures a snug fit and secure fastening. This guide will walk you through the proper drilling techniques to achieve the best results.

Proper Drilling Methods

Using the right drilling methods makes a big difference. Follow these steps to ensure accuracy:

- Select the correct drill bit size. For a #10 machine screw, a 7/32″ bit is ideal.

- Mark the drilling spot using a center punch. This prevents the drill from slipping.

- Secure the material with clamps to avoid movement during drilling.

- Drill at a slow, steady speed. High speeds can cause overheating and damage.

- Keep the drill perpendicular to the surface. This ensures a straight, clean hole.

Avoiding Common Mistakes

Many errors can occur during drilling. Here are some tips to avoid common mistakes:

- Don’t use a worn-out drill bit. It can cause rough holes and tool damage.

- Avoid applying too much pressure. Let the drill do the work to prevent breakage.

- Double-check the drill bit size. Using the wrong size can lead to loose screws.

- Keep the drill bit cool. Pause to let it cool down to avoid overheating.

- Use cutting oil for metal surfaces. It reduces friction and extends bit life.

Following these techniques and avoiding common mistakes will help you achieve the perfect hole for your #10 machine screw.

Tools And Materials Needed

When working with a #10 machine screw, knowing the right tools and materials is crucial. This ensures precise and efficient work. Below, find the essentials you need to get started.

Essential Tools

Having the right tools makes the job easier. Here are some tools you will need:

- Drill – A power drill with variable speed settings.

- Drill Bits – A set of drill bits, especially the right size for #10 screws.

- Tap Wrench – Used for threading the hole.

- Center Punch – Helps in marking the spot to drill.

- Measuring Tape – For accurate measurements.

- Safety Gear – Safety glasses and gloves.

Material Considerations

The material you’re drilling into affects the drill bit size and type. Consider the following:

| Material | Recommended Drill Bit Size |

|---|---|

| Wood | 7/64 inch |

| Plastic | 7/64 inch |

| Metal | 7/64 inch |

Always use a drill bit slightly smaller than the screw size. This ensures a tight fit.

Pro Tip: Use lubricant when drilling into metal. This reduces heat and extends the life of your drill bit.

Safety Tips

Choosing the right drill bit size for a #10 machine screw is crucial. Equally important is maintaining safety throughout the drilling process. Here are some essential safety tips to keep in mind while drilling.

Protective Gear

Before starting, always wear the necessary protective gear. This includes safety goggles to protect your eyes from debris. Use ear protection to guard against loud drilling noises.

Gloves are also important. They protect your hands from sharp edges and hot surfaces. Wear a dust mask if drilling materials that produce fine dust.

Safe Drilling Practices

Ensure the drill bit is securely fastened in the chuck. Loose bits can cause accidents. Keep your work area clean and free of clutter.

Always use a clamp to secure the material being drilled. This prevents movement that can lead to injury. Maintain a firm grip on the drill. Apply steady pressure without forcing the bit.

Drill at a consistent speed. Avoid sudden starts or stops that can break the bit. Turn off the drill and unplug it when changing bits.

Following these safety tips ensures a smooth and safe drilling experience.

Credit: drillsandcutters.com

Frequently Asked Questions

What Size Drill Bit For 10 Machine Screw?

For a #10 machine screw, use a 7/32 inch drill bit. This ensures a proper fit.

How Do I Choose The Right Drill Bit Size?

Match the drill bit size to the screw’s diameter. For #10 screws, use a 7/32 inch bit.

Can I Use A Different Drill Bit Size?

It’s best to use the recommended size. For #10 machine screws, a 7/32 inch bit ensures a secure fit.

Why Is Drill Bit Size Important?

Using the correct drill bit size ensures a secure and proper fit. It prevents damage and loosening.

Conclusion

Choosing the right drill bit for a #10 machine screw is crucial. A 9/64 inch drill bit works well. It ensures a proper fit and secure hold. Always double-check sizes before drilling. This simple step can save time and effort.

Precise drilling enhances project quality. So, remember to use the correct drill bit size. Your projects will benefit from this attention to detail. Happy drilling!