Finding the right drill bit size for an 8/32 machine screw is crucial. It ensures a perfect fit and secure fastening.

In this guide, we’ll explore the exact drill bit size needed for an 8/32 machine screw. Using the right drill bit size is key to a smooth project. It prevents damage to materials and ensures the screw holds firmly. Whether you’re a seasoned DIY enthusiast or a beginner, knowing the correct size can save you time and frustration.

In this post, we will provide you with clear information and tips. This will help you achieve the best results for your project. So, let’s dive in and find out the precise drill bit size for your 8/32 machine screw needs.

Introduction To Drill Bit Sizes

Choosing the right drill bit size is crucial for a secure fit. For an 8/32 machine screw, use a #29 drill bit. This ensures proper threading and a strong hold.

Understanding drill bit sizes is crucial for any DIY project. Especially when working with machine screws. You need the right size for a perfect fit.Importance Of Correct Drill Bit Size

Using the correct drill bit size ensures a tight, secure hold. This prevents damage to materials and enhances the durability of the assembly. A mismatched size can lead to loose fittings or stripped screws.Common Drill Bit Sizes

Drill bits come in many sizes. The most common sizes range from 1/16 inch to 1/2 inch. For an 8/32 machine screw, you typically need a #29 drill bit. This provides the right fit for threading. “`

Credit: www.amazon.com

Understanding 8/32 Machine Screws

Machine screws come in many sizes and types. One common type is the 8/32 machine screw. Knowing the right drill bit size for an 8/32 machine screw is crucial. This ensures proper fitting and avoids damaging the material or the screw.

What Is An 8/32 Machine Screw?

An 8/32 machine screw has a diameter of 8 and 32 threads per inch. They are commonly used for securing components in electronics, machinery, and more. The threads of these screws are fine, making them ideal for precise applications.

Applications Of 8/32 Machine Screws

8/32 machine screws are versatile. They are used in various fields:

- Electronics: Securing circuit boards and components.

- Machinery: Assembling parts and panels.

- Furniture: Joining pieces together.

Choosing the right drill bit ensures the screw fits snugly. This prevents loosening and ensures the assembly is durable.

Choosing The Right Drill Bit Size

Finding the correct drill bit size for an 8/32 machine screw is crucial. The right size ensures a snug fit and secure hold. This section will guide you through the process.

Factors To Consider

Several factors affect the choice of drill bit size. Here are the key considerations:

- Material: The type of material you’re drilling into affects bit size.

- Screw Type: Different screws may need different bit sizes.

- Thread Count: Higher thread count may need a smaller bit.

Common Mistakes To Avoid

Avoid these common mistakes when choosing a drill bit size:

- Using Too Large a Bit: This can cause the screw to be loose.

- Using Too Small a Bit: This can make it difficult to insert the screw.

- Ignoring Material Type: Different materials require different bit sizes.

Choosing the correct drill bit size is essential. Remember these tips for better results.

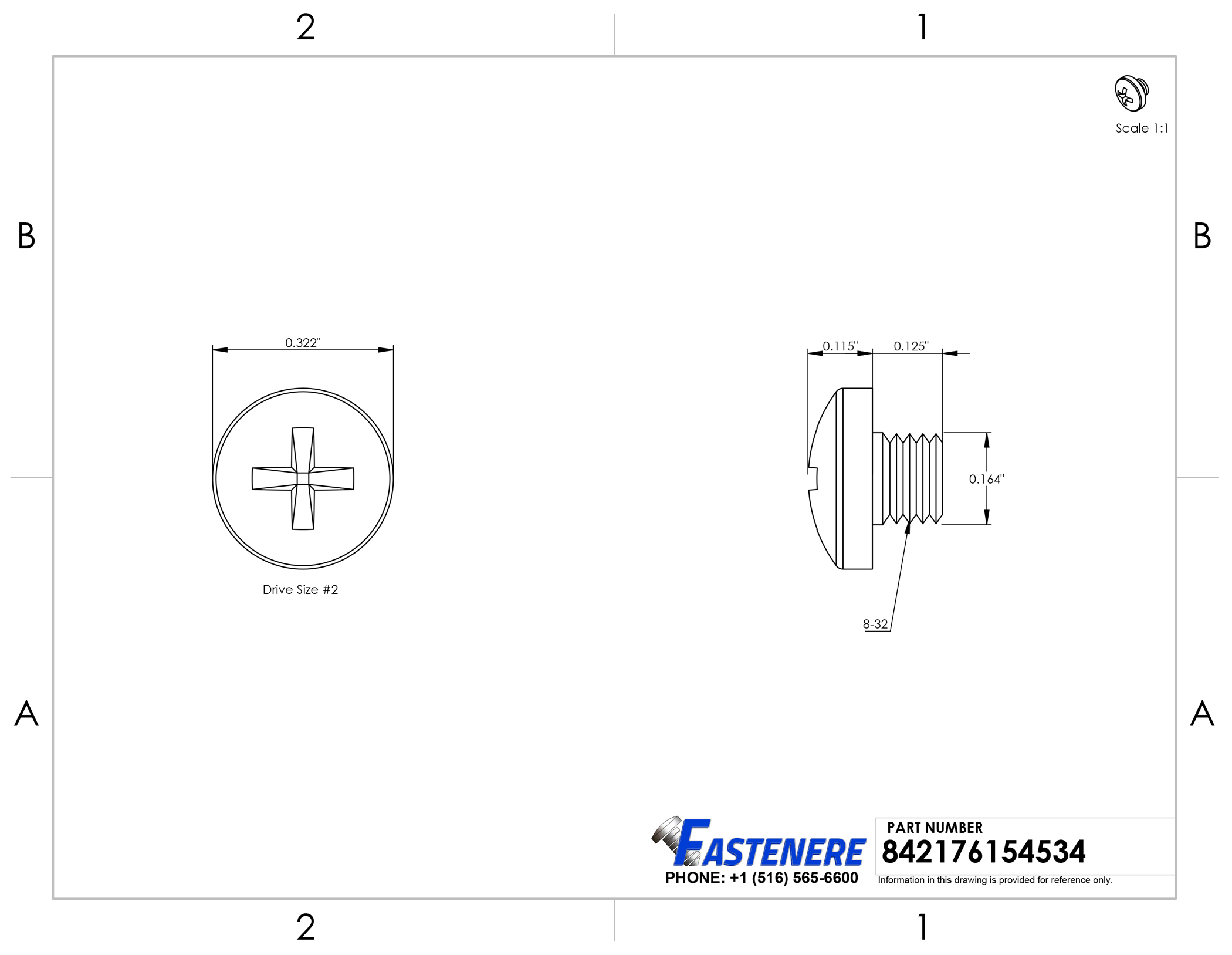

Credit: www.fastenere.com

Recommended Drill Bit Size For 8/32 Machine Screw

For an 8/32 machine screw, use a #29 drill bit. This size ensures a proper fit and secure threading.

Choosing the correct drill bit size is crucial for a secure fit. An 8/32 machine screw requires a specific size to work properly. The right size ensures your screw threads properly and provides a strong hold.Standard Drill Bit Size

The standard drill bit size for an 8/32 machine screw is a #29 bit. This size creates a hole with a diameter of 0.136 inches. This measurement allows the screw to thread securely without stripping. Using a #29 bit helps in achieving a perfect fit for your screw.Alternative Sizes

In some situations, you might need to use an alternative size. A #28 bit can be used if a tighter fit is desired. This bit has a diameter of 0.140 inches. It provides a snugger fit for the screw. For a slightly looser fit, you can use a #30 bit. This bit has a diameter of 0.128 inches. It offers a bit more room for the screw, which can be useful in softer materials. Using the correct drill bit size is essential for the strength and stability of your screw connection. Always ensure that the bit size matches your specific requirements. “`Step-by-step Guide To Drilling

Choosing the right drill bit is crucial. For an 8/32 machine screw, use a #29 drill bit. This ensures a perfect fit and secure fastening.

Drilling holes for an 8/32 machine screw can seem tricky. This guide simplifies the process. Follow these steps for a perfect fit.Preparation Steps

First, gather your tools. You need a drill, an 8/32 machine screw, and the correct drill bit size. For an 8/32 machine screw, use a #29 drill bit. This bit has a diameter of 0.136 inches. Next, mark the spot where you need the hole. Use a pencil or marker for precision. Ensuring accuracy at this stage saves time later. Secure the material you will drill into. Use a clamp or vise to hold it steady. Safety is crucial.Drilling Techniques

Begin by aligning the drill bit with the marked spot. Hold the drill steady. Start drilling at a low speed. Press gently to avoid slipping. Maintain a straight angle to ensure a clean hole. Increase the speed gradually as the bit goes deeper. Keep a firm grip on the drill. Consistent pressure is key. Pull the drill bit out occasionally. This clears away debris. It also prevents overheating. Check the hole size once drilled. The 8/32 machine screw should fit snugly. If it’s too tight, slightly widen the hole. Repeat the process if necessary. Practice improves skill. By following these steps, drilling for an 8/32 machine screw becomes straightforward and easy. Happy drilling! “`

Credit: drillsandcutters.com

Tools And Equipment Needed

Drilling the correct size hole for an 8/32 machine screw requires the right tools and equipment. This section will guide you through the essential tools and safety gear needed. Follow these steps to ensure a precise and safe drilling process.

Essential Tools

To drill a hole for an 8/32 machine screw, you need a few key tools. First, get a drill with variable speed settings. This helps you control the drilling process better. Second, use a 9/64-inch drill bit. This size matches the screw and ensures a snug fit. Third, have a center punch. This tool marks the spot where you will drill, preventing the bit from wandering. Fourth, use a clamp. This secures the material, keeping it steady while you drill. Lastly, have a screwdriver on hand. This helps you insert the screw once the hole is ready.

Safety Gear

Safety is crucial when using power tools. Always wear safety glasses. They protect your eyes from flying debris. Gloves are also important. They shield your hands from sharp edges and hot surfaces. Wear a dust mask. Drilling can create dust that is harmful if inhaled. Ear protection is also advisable. Drills can be noisy, and earplugs or earmuffs will protect your hearing. Lastly, wear a long-sleeve shirt and long pants. These provide an extra layer of protection against sharp or hot materials.

Tips For Successful Drilling

Drilling the correct hole size for an 8/32 machine screw can be tricky. Using the wrong drill bit can result in a loose or tight fit. Following a few tips can help you achieve successful drilling and ensure your projects are sturdy and reliable.

Best Practices

First, always use a sharp drill bit. A dull bit can cause the hole to be uneven. This can lead to poor screw fit. Second, secure your material properly before drilling. Movement can cause an inaccurate hole. Third, use a center punch to mark the drilling spot. This helps keep the drill bit from wandering.

Fourth, drill at a steady, moderate speed. High speeds can overheat the drill bit. Overheating can damage both the bit and the material. Fifth, use cutting oil if drilling metal. This reduces friction and heat. Finally, check the hole size with a gauge before inserting the screw. This ensures the fit is correct.

Common Issues And Solutions

One common issue is a hole that is too large. This often happens when the drill bit is not centered. To fix this, use a smaller bit to start the hole. Then switch to the correct size. Another issue is a hole that is too small. This can occur if the drill bit size is incorrect. Always double-check your bit size before drilling.

Sometimes, the drill bit may break. This usually happens due to excessive force or incorrect speed. Use gentle pressure and the right speed for the material. If the material is hard, like metal, ensure you use cutting oil. This reduces the risk of breaking the bit.

Lastly, misaligned holes can cause problems. Ensure your material is clamped securely. Use a guide or jig if needed. This helps keep the drill bit straight and aligned.

Frequently Asked Questions

What Size Drill Bit For 8/32 Screw?

For an 8/32 machine screw, a #29 drill bit is recommended. This ensures a secure fit.

How Do I Choose Drill Bit Size?

Match the drill bit size to the screw’s minor diameter. This ensures proper threading.

What Is A 29 Drill Bit?

A #29 drill bit measures 0. 136 inches or 3. 45mm. It’s ideal for 8/32 screws.

Can I Use A Different Drill Bit?

Using a different size can affect the screw’s grip. Stick to #29 for best results.

Conclusion

Choosing the right drill bit size for an 8/32 machine screw is crucial. It ensures a tight, secure fit. A 9/64 inch bit usually works best. Always double-check your drill bit size before starting. This avoids frustration and damage. Proper tools and preparation make any project easier.

Remember, measure twice, drill once. With these tips, you can confidently tackle your next task. Happy drilling!