The water separator on your air compressor should be placed as close to the compressor outlet as possible, before any tools or air lines, to effectively capture moisture and protect your equipment.

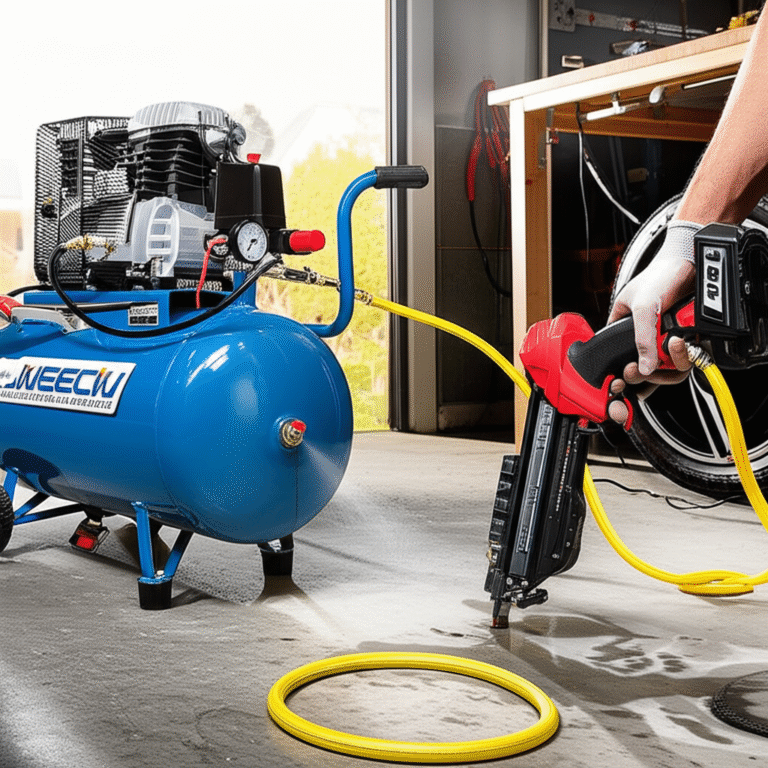

Air compressors are fantastic tools for all sorts of jobs, from inflating tires to powering your nail gun. But have you ever noticed little water droplets or a misty spray coming out of your air tools? That’s not ideal! It’s caused by moisture that naturally builds up in compressed air. This moisture can damage your tools and ruin paint jobs. You might be wondering, “Where does this little gizmo, the water separator, actually go?” It’s a common question, and getting it right is key to keeping your air compressor and your projects running smoothly. Don’t worry, we’ll walk through it step-by-step so you can get this sorted out easily.

Why Water Separators Are a Big Deal

Think of a water separator as a tiny guardian for your air compressor system. When air gets compressed, it heats up. As it cools down, water vapor in the air turns into liquid water. This water can cause a few problems:

Rust: It can cause the inside of your air tank and tools to rust.

Tool Damage: Water can gum up the delicate parts inside air tools, leading to poor performance or even complete failure.

Poor Finish: If you’re painting, water in the air line can cause blemishes, bubbles, or an uneven finish.

Reduced Efficiency: Moisture can make your tools less effective.

A water separator is designed to catch this water before it travels through your air lines and into your tools.

Understanding the Air Compressor System Flow

To know where the water separator goes, it helps to understand how air moves through your compressor system. It’s a pretty straightforward path:

1. Air Intake: The compressor draws in ambient air.

2. Compression: The pump compresses this air, increasing its pressure.

3. Cooling: The compressed air cools down, often in the tank or via cooling fins. This is where moisture forms.

4. Storage: The compressed air is stored in the air tank.

5. Distribution: The air travels out of the tank, through hoses, and to your tools.

The goal is to intercept the water after it has been compressed and cooled, but before it reaches your valuable tools.

Where to Place Your Water Separator: The Sweet Spot

The absolute best place for a water separator is as close to the air compressor’s main outlet as possible, before any hoses or other accessories.

Here’s why this location is critical:

Captures All Moisture: This ensures that any water that condenses in the tank or in the initial part of the air line is caught.

Protects Everything Downstream: By placing it here, you’re creating a barrier that protects all subsequent components, including air hoses, regulators, filters, and the tools themselves.

Easy Access for Draining: You’ll want to drain your water separator regularly, so having it in an accessible spot near the compressor is convenient.

Imagine your air system as a river. You want to put your water filter where the river exits the main reservoir, before it flows into smaller streams that lead to different gardens.

Visualizing the Setup

A typical setup would look like this:

Air Compressor Tank Outlet → Water Separator → Air Hose → (Optional: Regulator/Filter) → Air Tool

If you have multiple tools or a longer hose setup, you might also consider secondary filters or separators closer to the tools, but the primary, most important one goes right at the source.

Types of Water Separators and Their Placement

There are a few common types of water separators you might encounter:

1. In-Line Water Separators

These are the most common and are designed to be plumbed directly into the air line.

How they work: They typically use a combination of centrifugal force (spinning the air to fling water outwards) and a coalescing element to trap moisture.

Placement: They have inlet and outlet ports, usually with threaded fittings. You’ll connect a short nipple or fitting from your compressor’s tank outlet to the inlet of the separator, and then another fitting from the separator’s outlet to your main air hose.

Draining: Most have a small valve or petcock at the bottom for draining. Some have automatic drains.

Example Placement:

[Compressor Tank Outlet] -- [Fitting] -- [In-Line Water Separator] -- [Fitting] -- [Air Hose]2. Filter/Regulator/Lubricator (FRL) Units

These are often found in more professional or industrial settings, but smaller versions are available for DIYers. An FRL unit combines filtration, pressure regulation, and sometimes lubrication in one package. The filtration component of an FRL unit will act as a water separator.

How they work: They combine multiple functions. The filter part will trap water and particulates.

Placement: Similar to in-line separators, they are placed after the compressor outlet and before the air hose. They often have a mounting bracket to attach them to a wall or workbench near the compressor.

Draining: Usually feature a drain bowl at the bottom that can be manually or automatically drained.

Example Placement:

[Compressor Tank Outlet] -- [Fitting] -- [FRL Unit (Filter Section)] -- [Air Hose]3. Desiccant Dryers

While not strictly “water separators” in the same way, desiccant dryers remove moisture from the air by using a material that absorbs water.

How they work: Air passes through a bed of desiccant material, which adsorbs the water vapor.

Placement: These are usually placed further down the line, often just before the tool, especially for critical applications like painting. However, a primary desiccant dryer can also be placed after the compressor outlet.

Draining: The desiccant needs to be periodically dried out or replaced.

For most beginner users, an in-line water separator is the most common and effective solution.

Step-by-Step Installation Guide for an In-Line Water Separator

Let’s get this installed! You won’t need a lot of fancy tools for this.

What You’ll Need:

Your new in-line water separator

Pipe thread sealant tape (Teflon tape)

Adjustable wrench or pipe wrench

A rag for cleaning

Installation Steps:

1. Ensure Compressor is Off and Depressurized: Safety first! Turn off your air compressor and bleed any remaining air pressure from the tank by opening the drain valve or pulling the pressure relief valve.

2. Locate the Compressor Outlet: Find the main air outlet port on your air compressor tank. This is usually a threaded fitting where you connect your primary air hose.

3. Remove Existing Fitting (if any): If there’s already a fitting or quick-connect coupler attached, use your wrench to carefully unscrew it.

4. Prepare the Water Separator Threads: Take your water separator. You’ll see an inlet port and an outlet port. Apply pipe thread sealant tape (Teflon tape) to the threads of the inlet port of the water separator. Wrap the tape clockwise around the threads, typically 3-4 times, ensuring it’s snug.

5. Connect to Compressor Outlet: Screw the water separator’s inlet port onto the compressor’s outlet port. Hand-tighten it first, then use your wrench to tighten it an additional half to three-quarters of a turn. Don’t overtighten, as this can damage the threads. Ensure the separator is oriented so the outlet port faces the direction your air hose will run.

6. Prepare the Outlet Fitting: Apply Teflon tape to the threads of a fitting that will connect your air hose to the outlet port of the water separator. This might be a male-to-male nipple or a quick-connect coupler.

7. Connect the Air Hose: Screw the fitting onto the outlet port of the water separator. Tighten it with your wrench. Then, connect your air hose to this fitting.

8. Check for Leaks: Turn on your air compressor and let it build pressure. Listen carefully for any hissing sounds around the connections you just made. If you hear a leak, turn off the compressor, depressurize, and slightly tighten the leaking connection or reapply Teflon tape if necessary.

9. Drain Regularly: Remember to drain the water separator frequently. Most have a small valve at the bottom. You can manually open this valve to release the collected water. Some have automatic drains that open when pressure drops.

Tips for Maximizing Water Separation

Drain Often: The most crucial tip is to drain your separator regularly. If you use your compressor daily, try to drain it at the end of each workday.

Consider a Cold-Weather Drain: If you live in a cold climate, make sure your drain valve is accessible and won’t freeze up.

Use a Secondary Filter: For critical applications like painting or powering sensitive pneumatic tools, consider adding a secondary filter or a desiccant dryer further down the line, closer to the tool. This provides an extra layer of protection.

Maintain Your Compressor: Regularly draining your air compressor tank itself is also vital. Water collects in the tank too! Many compressors have a petcock valve at the very bottom of the tank for this purpose.

* Check Air Quality: Periodically inspect your tools and hoses for any signs of moisture or rust. This can help you identify if your water separator is working effectively or if you need to upgrade.

When to Use Different Types of Moisture Control

The complexity of your moisture control system often depends on your application.

| Application | Recommended Moisture Control