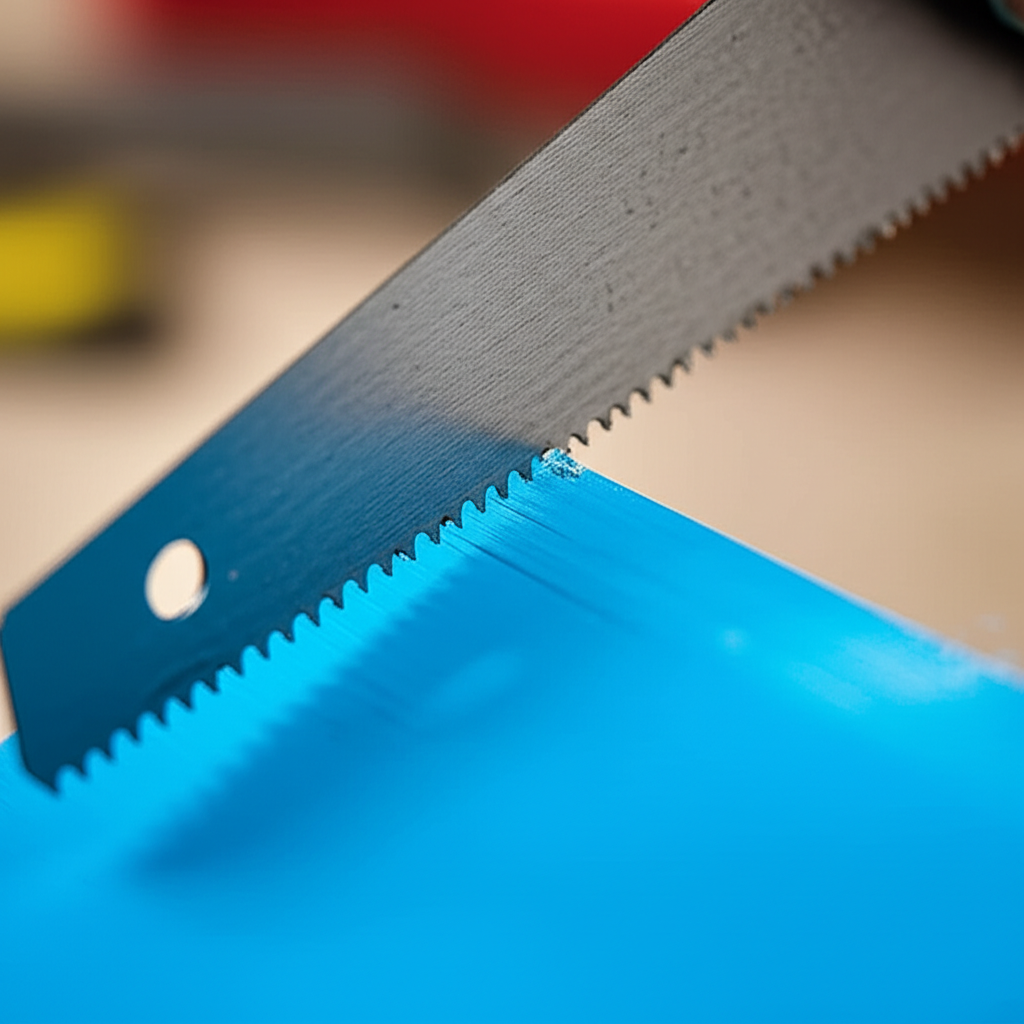

For cutting plastic with a hacksaw, choose a blade with a higher TPI (Teeth Per Inch) – ideally 18 TPI or higher – and a fine-set tooth pattern. This prevents the plastic from melting and gumming up the blade, ensuring a clean, smooth cut.

Ever stared at a pile of plastic, a trusty hacksaw in hand, and wondered, “Which blade do I even use for this?” It’s a common puzzle! Trying to cut plastic with the wrong hacksaw blade can be a frustrating experience. You might end up with jagged edges, melted plastic stuck to your blade, or even a broken blade. But don’t worry, it doesn’t have to be that way. With the right blade and a few simple tips, you can cut plastic cleanly and easily. We’ll walk you through exactly what you need to know to pick the perfect hacksaw blade for your plastic projects, making your DIY tasks smoother and more successful.

Understanding Your Hacksaw Blade: The Key to Cutting Plastic

A hacksaw is a versatile tool, but its effectiveness really comes down to the blade you choose. Think of the blade as the business end of your saw – it’s what does all the hard work. When it comes to cutting different materials, the blade’s design is crucial. For plastic, this means paying close attention to two main features: the TPI (Teeth Per Inch) and the tooth set.

What is TPI (Teeth Per Inch)?

TPI is exactly what it sounds like: it’s the number of teeth that fit into one inch of the blade. This is a super important spec for any cutting job.

- Lower TPI (e.g., 14-18 TPI): These blades have fewer, larger teeth. They’re great for cutting thicker, softer materials like wood or thicker metals. The larger teeth remove material quickly.

- Higher TPI (e.g., 24-32 TPI): These blades have more, smaller teeth. They’re designed for cutting thinner materials and provide a smoother, cleaner finish.

When you’re cutting plastic, especially softer or more flexible types, you want to avoid those big, aggressive teeth. Why? Because they can grab the plastic, cause it to chip, or worse, melt it. Melting is a big problem because the softened plastic can gum up the teeth, making the blade less effective and potentially damaging it.

What is Tooth Set?

Tooth set refers to how the teeth on the blade are angled. There are a few common types:

- Regular Set: The teeth alternate to the left and right in a regular pattern. This is common for general-purpose cutting.

- Raker Set: One tooth is bent to the left, one to the right, and one is straight (or set back). This creates a wider kerf (the width of the cut) and helps clear chips.

- Wavy Set: Teeth are bent in a wavy pattern. This is often found on blades for cutting thin metals and tubing, as it allows for a smoother cut on thinner materials by reducing the number of teeth in contact at any one time.

For plastic, you generally want a blade where the teeth aren’t too aggressive. A fine-set pattern, often seen on blades with higher TPI, is usually best. The wavy set can be particularly good for plastics because it minimizes the surface area of the teeth that are engaging with the material at any given moment, reducing friction and the chance of melting.

The Best Hacksaw Blades for Cutting Plastic: Your Go-To Guide

So, what’s the magic combination for cutting plastic? It’s all about finding that sweet spot between blade sharpness and tooth configuration to get a clean cut without the melt-and-gum-up disaster.

Recommended Blade Specifications for Plastic

When you’re at the hardware store or browsing online, look for these specs:

- TPI: 18 TPI to 32 TPI. For most common plastics, 18 TPI is a good starting point, especially for slightly thicker pieces. For thinner plastics or when you need a very smooth finish, go up to 24 TPI or even 32 TPI.

- Tooth Type: Fine-set or Wavy Set. These tooth patterns are designed to cut smoothly and reduce the risk of melting.

- Material: Bi-metal blades are excellent. These blades combine a flexible spring steel back with high-speed steel teeth. They’re durable, heat-resistant, and less prone to shattering, making them a great all-around choice for various materials, including plastics.

Blade Types to Consider (and Why)

Let’s break down the common types of hacksaw blades and how they fare with plastic:

| Blade Type | Typical TPI | Best For | Pros for Plastic | Cons for Plastic |

|---|---|---|---|---|

| High-Speed Steel (HSS) | 24-32 TPI | Thin metals, tubing | Durable, good heat resistance, fine teeth for clean cuts. | Can be brittle if flexed too much. |

| Bi-Metal | 18-32 TPI | General purpose, metals, plastics | Flexible yet durable, good heat resistance, can handle a variety of materials including plastic well. | Slightly more expensive than carbon steel. |

| Carbon Steel | 14-24 TPI | Wood, softer metals | Inexpensive. | Less heat resistant, teeth can dull or melt plastic more easily, not ideal for fine plastic cuts. |

For most plastic cutting tasks, a bi-metal blade with 18-24 TPI and a fine or wavy set is your safest bet. It offers a good balance of speed, smoothness, and durability.

When to Use Different TPIs for Plastic

The thickness and type of plastic really influence the best TPI:

- Thin Plastic Sheets (e.g., acrylic, polycarbonate, PVC sheeting under 1/8″): Aim for 24-32 TPI. These blades will give you a very clean, smooth edge with minimal chipping. The fine teeth prevent the plastic from grabbing and melting.

- Medium Thickness Plastic (e.g., PVC pipe, thicker acrylic, ABS sheets): 18-24 TPI is usually perfect. This range offers enough tooth engagement to cut efficiently without being so aggressive that it causes melting or excessive chipping.

- Thick or Hard Plastics (e.g., certain engineering plastics): You might still lean towards 18 TPI, but ensure the tooth set is fine. For very hard plastics, you might even consider specialized plastic cutting blades if available, but a good bi-metal 18 TPI blade will often do the job.

It’s important to remember that plastic is a broad category. Acrylic, PVC, ABS, polycarbonate, and nylon all behave differently when cut. Generally, the softer or more flexible the plastic, the higher the TPI you’ll want.

How to Cut Plastic with a Hacksaw: Step-by-Step

Now that you know which blade to grab, let’s talk about the actual cutting process. Following these steps will help you achieve a clean, frustration-free cut every time.

Step 1: Choose and Install the Right Blade

As we’ve discussed, select a hacksaw blade with a higher TPI (18-32) and a fine or wavy tooth set. Ensure it’s a bi-metal or HSS blade for best results. To install it:

- Loosen the wing nut or screw on the hacksaw frame to release tension on the blade.

- Remove the old blade (if any).

- Insert the new blade into the slots on the frame. Make sure the teeth are facing away from the handle – this is the direction the saw cuts.

- Tension the blade by tightening the wing nut or screw. The blade should be taut, like a guitar string. A loose blade will bend and break easily.

Step 2: Secure Your Plastic

This is crucial for a clean cut and your safety. Plastic can easily shift or spin while you’re cutting.

- Use a Vice: The best way to secure plastic is in a vice. Clamp the plastic firmly, but not so tightly that you crack or deform it. If you’re cutting a pipe, use pipe jaws or wrap the plastic with a cloth or scrap wood in the vice jaws to prevent marring.

- Use Clamps: If you don’t have a vice, use C-clamps or bar clamps to hold the plastic securely to a workbench or sturdy surface.

- Mark Your Cut Line: Use a fine-tip marker or a pencil to draw a clear line where you want to cut.

Step 3: Start the Cut

Getting the cut started smoothly is key to a good result.

- Backstroke Start: Begin by drawing the blade back gently across your marked line a few times. This creates a small groove that helps guide the blade and prevents it from jumping.

- Engage Teeth: Once you have a slight groove, start making forward strokes.

Step 4: Sawing Technique

This is where the magic happens. Focus on a smooth, consistent motion.

- Use the Full Blade: Let the entire length of the blade do the work. This distributes the wear and makes cutting more efficient.

- Apply Steady Pressure: Use moderate, consistent pressure on the forward stroke (when the teeth are cutting) and lift slightly or use very light pressure on the backstroke. Don’t force the blade.

- Maintain a 45-Degree Angle: Try to keep the hacksaw frame at a slight angle to the plastic, generally around 45 degrees. This helps the teeth engage the material effectively.

- Keep it Smooth: Avoid jerky movements. Smooth, rhythmic strokes are best for clean cuts and preventing the plastic from melting.

- Clear Debris: For longer cuts, you might need to periodically brush away any plastic shavings or dust.

Step 5: Finishing the Cut

As you get close to the end of the cut, be extra careful.

- Ease Up: Reduce the pressure as you near the end of the cut. This prevents the piece you’re cutting off from breaking off abruptly, which can leave a rough edge.

- Support the Piece: Make sure the piece you are cutting off is supported so it doesn’t break off unevenly.

Step 6: Finishing Touches

Once the cut is complete, you might want to clean up the edges.

- Deburr: Use a deburring tool, a sharp utility knife (carefully!), or fine-grit sandpaper (like 220 grit or higher) to smooth any rough edges or burrs left by the cut. For plastics like acrylic, you can sometimes use a file designed for plastic or even a specialized plastic deburring tool.

- Clean Up: Wipe away any dust or shavings.

Tips for Cutting Different Types of Plastic

Not all plastics are created equal, and some require a little extra care:

- Acrylic (Plexiglass): This can be prone to chipping and cracking. Use a high TPI blade (24-32) and a wavy set if possible. Go slowly and apply steady, even pressure. Some people even recommend using a cooling spray or a bit of water to prevent melting, though this isn’t always necessary with the right blade. For very clean edges, a fine-tooth blade on a scroll saw or a table saw with a specific plastic-cutting blade is often preferred, but a hacksaw can work with patience.

- PVC (Polyvinyl Chloride): This is generally easier to cut. A bi-metal blade with 18-24 TPI works well. PVC can sometimes melt slightly, so smooth, consistent strokes are important.

- ABS (Acrylonitrile Butadiene Styrene): Similar to PVC, ABS cuts relatively easily. An 18-24 TPI blade is suitable. Keep your strokes smooth to avoid melting.

- Polycarbonate (Lexan): This is a tough plastic that can also be prone to melting. Use a high TPI blade (24-32) and a fine tooth set. Slow and steady is the mantra here.

- Delrin (Acetal) and Nylon: These engineering plastics can be quite slippery and prone to melting. A high TPI (24-32) blade with a fine set is essential. Some people find that using a cutting lubricant designed for plastics can help reduce friction and prevent melting. You can find information on cutting various plastics from manufacturers like Boedeker Plastics, which offers detailed guides on machining different polymer types.

A general rule of thumb is that the harder and more brittle the plastic, the higher the TPI you’ll need. The softer and more flexible the plastic, the higher the TPI you’ll need to prevent melting and gumming.

Common Mistakes to Avoid When Cutting Plastic

Even with the right blade, you can run into trouble if you’re not careful. Here are some common pitfalls to sidestep:

- Using the Wrong Blade: This is the most common mistake. Using a coarse-tooth blade (like 14 TPI) will almost guarantee melting and a messy cut.

- Applying Too Much Pressure: Forcing the blade through the plastic will cause it to heat up, melt, and can lead to blade breakage or uneven cuts. Let the blade do the work.

- Not Securing the Plastic Properly: If the plastic moves or spins while you’re cutting, you’ll get a rough, inaccurate cut and it can be dangerous.

- Using a Dull Blade: A dull blade requires more force, increasing the chance of melting and making the cutting process much harder.

- Not Tensing the Blade Correctly: A loose blade will bend, skip teeth, and likely break. Ensure it’s taut in the frame.

- Jerky Sawing Motion: Smooth, consistent strokes are key for clean cuts.

When to Consider Other Tools

While a hacksaw is a great tool for many plastic cutting tasks, sometimes other tools are better suited, especially for very precise or large cuts:

- Utility Knife: For very thin plastic sheets (like styrene or thin acrylic), a sharp utility knife can make a clean cut. You’ll need to score the line multiple times.

- Jigsaw: With the right blade (a fine-tooth wood or plastic blade), a jigsaw is excellent for curved cuts or cutting thicker plastics.

- Circular Saw or Table Saw: For straight, long cuts in thicker plastics, these power tools are very efficient. You’ll need specialized blades designed for plastic to prevent melting and chipping. For example, Tools Today offers a variety of saw blades specifically designed for cutting plastics.

- Rotary Tool (Dremel): For small, intricate cuts or trimming, a rotary tool with a cutting disc designed for plastic can be useful.

However, for general repairs, hobby projects, or when you only have a hacksaw available, knowing how to use it effectively for plastic is a valuable skill.

Frequently Asked Questions (FAQ)

What TPI hacksaw blade is best for cutting PVC pipe?

For PVC pipe, an 18 TPI or 24 TPI hacksaw blade with a fine or wavy tooth set is ideal. This will provide a clean cut without melting the plastic.

Can I use a hacksaw to cut acrylic sheets?

Yes, you can cut acrylic sheets with a hacksaw, but it requires the right blade. Use a blade with a high TPI (24-32) and a fine tooth set to prevent chipping and melting. Go slowly and use steady pressure.