Choosing the right hacksaw blade for your project makes all the difference for clean, efficient cuts. For general metalwork, a 24 TPI blade is your go-to. For harder metals or thinner materials, opt for a 32 TPI blade. For softer materials like plastic or conduit, a 18 TPI blade works well. Always match the TPI to the material thickness for the best results and a frustration-free experience.

Ever stared at a pile of materials, ready to tackle a project, only to be stumped by the array of hacksaw blades? You’re not alone! It can feel a bit overwhelming, especially when you just want to make a clean cut without a fuss. The good news is, picking the right blade isn’t rocket science. It’s all about understanding a few simple things, and I’m here to walk you through it, step-by-step. We’ll demystify TPI, explore the best blades for different jobs, and get you cutting like a pro in no time. Get ready to feel confident and capable with your hacksaw!

Understanding Your Hacksaw Blade: The Tooth Count (TPI) Matters!

The most important thing to know about hacksaw blades is their TPI, which stands for Teeth Per Inch. Think of it like this: the more teeth packed into an inch of the blade, the finer the cut. This is super important because using the wrong TPI can lead to a rough cut, break the blade, or even damage your material. It’s like trying to slice a tomato with a bread knife – it just doesn’t work as well!

Here’s a simple breakdown:

- High TPI (e.g., 24-32 TPI): More teeth mean finer cuts. These are best for harder metals and thinner materials. The smaller teeth grip the material better, preventing snagging and producing a smoother finish.

- Low TPI (e.g., 14-18 TPI): Fewer teeth mean coarser cuts. These are ideal for softer metals and thicker materials. The larger teeth remove material more quickly and are less likely to get clogged.

A good rule of thumb to remember is: use more teeth for thinner materials, and fewer teeth for thicker materials. This ensures that at least two teeth are always in contact with the material you’re cutting. This is crucial for a clean, efficient cut and to prevent the blade from snagging or breaking.

Choosing the Right Blade for the Job: Proven Cuts for Common Materials

So, you know about TPI, but which blade is actually best for what? Let’s break down some common materials and the hacksaw blades that work best for them. This is where the magic happens, turning that confusing array of blades into your helpful cutting toolkit.

Cutting Metal: The Most Common Task

Hacksaws are often thought of as metal-cutting tools, and for good reason. Whether you’re working with pipes, bolts, or metal stock, the right blade is key.

- Steel Pipe & Conduit: For standard steel pipes and electrical conduit, a 24 TPI blade is your best friend. It offers a good balance between cutting speed and a relatively smooth finish. You’ll find these blades are versatile for a wide range of metal thicknesses you’ll encounter in home repairs or DIY projects.

- Thin Sheet Metal: When you’re cutting thinner sheet metal, like that found in ductwork or some craft projects, you need more teeth to avoid snagging. A 32 TPI blade is perfect here. The finer teeth will bite into the thin metal without catching and potentially bending or tearing the material.

- Thicker Metal Stock (e.g., Angle Iron, Solid Rod): For tougher, thicker pieces of metal, you might lean towards a 18 TPI blade. While 24 TPI can still work, the 18 TPI blade will remove material a bit faster. Just be sure you’re maintaining good contact with the material, as with any blade choice.

- Aluminum: Aluminum is softer than steel. For aluminum tubing or stock, a 24 TPI blade is generally a good choice. You could also use an 18 TPI blade if the aluminum is quite thick, but 24 TPI offers a cleaner cut for most common applications.

Cutting Plastic: Smooth and Easy

Plastic is another material many DIYers encounter. From PVC pipes for plumbing projects to acrylic sheets for crafting, a hacksaw can handle it.

- PVC Pipe & Plastic Tubing: For most PVC pipes, especially those used in plumbing or garden projects, a 18 TPI blade is excellent. The larger teeth cut through the plastic quickly and efficiently, and they are less likely to clog than finer-toothed blades.

- Acrylic Sheets & Thicker Plastics: When cutting thicker acrylic sheets or other hard plastics, you might want to switch to a 24 TPI blade. This will give you a cleaner edge and reduce the risk of chipping or cracking the plastic. Always cut slowly and steadily with plastic.

Cutting Wood: When a Handsaw Isn’t an Option

While a dedicated wood saw is usually preferred for woodworking, a hacksaw can be a lifesaver for small cuts on wood, especially in tight spaces or when you only have a hacksaw available.

- General Wood Cuts: For general wood cutting, a 14 TPI or 18 TPI blade is recommended. These coarser teeth are designed to clear wood chips effectively, preventing the blade from binding. If you’re cutting very thin wood or plywood, you might find a 24 TPI blade works better to avoid splintering.

Blade Material: What’s It Made Of?

Beyond TPI, the material your hacksaw blade is made from also plays a role in its performance and durability. Understanding these materials can help you make a more informed choice, especially if you’re cutting a lot of tough stuff.

Here’s a quick look at common blade materials:

| Blade Material | Pros | Cons | Best For |

|---|---|---|---|

| High-Carbon Steel (HCS) | Inexpensive, flexible, good for soft metals and wood. | Dulls quickly, not ideal for hard metals or heavy-duty use. | Wood, soft plastics, general purpose light cutting. |

| High-Speed Steel (HSS) | Harder than HCS, holds an edge longer, can cut harder materials. | More brittle, can snap if flexed too much, more expensive than HCS. | Various metals (including mild steel), harder plastics. |

| Bi-Metal | Combines a flexible steel back with HSS teeth. Very durable, shatter-resistant, long-lasting, versatile. | More expensive than HCS or HSS alone. | Almost all materials: various metals, plastics, wood. Excellent all-around choice. |

For most beginners and for general DIY tasks, bi-metal blades are an excellent investment. They offer the best combination of durability, flexibility, and cutting performance across a wide range of materials. They are more forgiving if you’re still getting the hang of your cutting technique.

How to Get the Best Cut: Technique Tips

Having the right blade is only half the battle. Your technique is just as important for getting clean cuts and making your work easier and safer. Don’t worry, these are simple things you can practice right away!

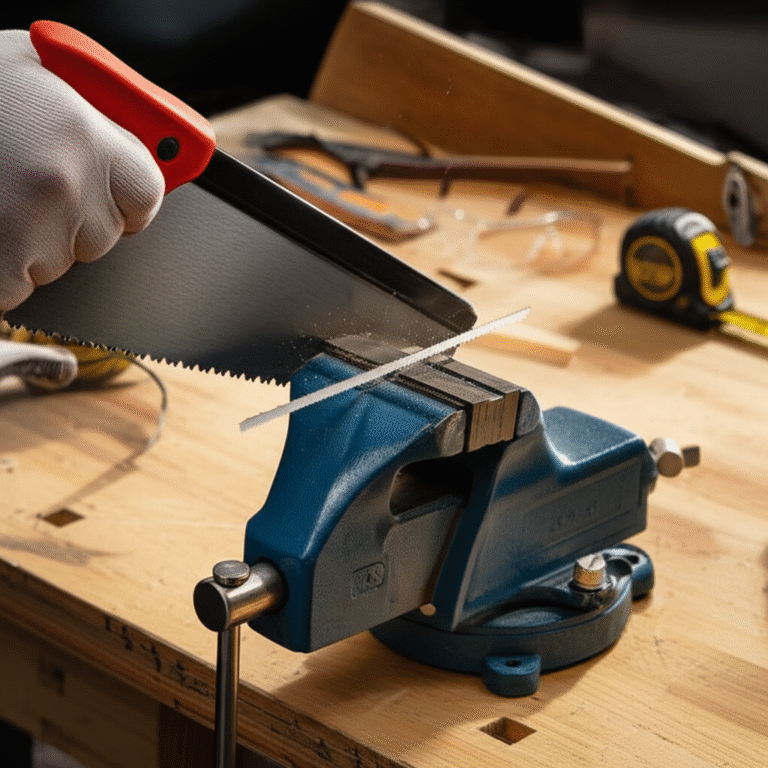

- Secure Your Material: Always clamp your workpiece firmly in a vise or with clamps. A wobbly piece is hard to cut accurately and can be dangerous. Make sure the part you want to cut is close to the vise jaws to prevent bending.

- Proper Blade Tension: Ensure your hacksaw blade is tensioned correctly. It should be tight enough to cut straight, but not so tight that it snaps. When you pluck a properly tensioned blade, it should make a high-pitched “ping” sound, not a dull “thud.” Many hacksaws have tension indicators, or you can learn to feel it. A loose blade will wander and make a mess.

- Start the Cut: To prevent the blade from slipping, create a small notch or guide mark with a file or a center punch where you want to start cutting. Place the blade on the mark and make a few short, backward strokes with light pressure to create a groove.

- The Cutting Stroke: Use long, smooth strokes. Apply steady pressure on the forward stroke (when the teeth are cutting) and lift the pressure on the backward stroke. Let the blade do the work! Aim for about 40-60 strokes per minute.

- Maintain Angle: Try to keep the blade at a consistent angle to the material. This helps distribute the cutting load evenly across the teeth and prevents the blade from binding or breaking.

- Coolant for Metal: When cutting metal, especially harder steels, using a cutting fluid or oil can help lubricate the blade, reduce heat buildup, and extend the life of the blade. This also helps create a cleaner cut. You can find specific cutting fluids at most hardware stores. For very light jobs, a bit of WD-40 can help in a pinch, though dedicated cutting fluid is better. The U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) has resources on metalworking processes that highlight the importance of lubrication for cutting efficiency and tool life.

- Clear Debris: Periodically, especially when cutting softer materials like plastic or wood, stop and brush away any accumulated chips or dust from the blade. This prevents the teeth from getting clogged and allows them to cut effectively.

Hacksaw Blade Types: Beyond the Standard

While the standard straight-edge hacksaw blade is what most people think of, there are a few variations you might encounter or find useful for specific tasks.

- All-Purpose Blades: These are usually bi-metal blades with a TPI count that’s a good compromise, often around 24 TPI. They are designed to handle a variety of materials reasonably well.

- Variable Tooth Blades: Some blades have a variable TPI pattern, meaning the number of teeth per inch changes along the blade. This is designed to offer better performance across a wider range of material thicknesses.

- Reciprocating Saw Blades (for Hacksaw Frames): Believe it or not, some specialized hacksaw frames can actually accept small reciprocating saw blades. This can offer more power and different cutting options, but it’s a more niche application.

For most beginners, sticking with standard, good-quality bi-metal blades in the appropriate TPI range (18, 24, or 32) will cover 95% of your needs. Focus on mastering the TPI selection and cutting technique first.

When to Replace Your Hacksaw Blade

Even the best hacksaw blades wear out. Knowing when to swap one out will save you a lot of frustration and ensure you’re always cutting efficiently. A dull blade won’t cut cleanly, will require more effort, and can even be more dangerous because it’s more likely to slip.

Here are signs your blade needs replacing:

- Slow Cutting: If it feels like you’re sawing through butter with a dull knife, the blade is likely worn out.

- Rough Cuts: The cut edges are jagged, splintered, or uneven, even with good technique.

- Blade Glazing: For plastics and some metals, a dull blade can cause the material to melt and re-harden around the teeth, making it difficult to cut.

- Missing Teeth: If you notice several teeth are broken or missing, the blade’s effectiveness is significantly reduced.

- Excessive Force Required: You find yourself having to push much harder than usual to make any progress.

It’s always a good idea to have a few spare blades on hand, especially if you plan on doing a lot of cutting. They are relatively inexpensive and make a huge difference in your project’s outcome.

Frequently Asked Questions About Hacksaw Blades

Q1: How do I know if my hacksaw blade is installed correctly?

A1: The teeth on the blade should always face away from the handle, in the direction of the cutting stroke (forward). Ensure the blade is securely tensioned in the frame.

Q2: Can I use a hacksaw blade on wood?

A2: Yes, you can, but it’s not ideal for large woodworking projects. Use a blade with a lower TPI (14-18 TPI) for wood to prevent clogging. A dedicated wood saw will give cleaner results for woodworking.

Q3: What’s the difference between a hacksaw blade and a coping saw blade?

A3: Hacksaw blades are thicker, wider, and designed for straight cuts in metal and plastic. Coping saw blades are much thinner and narrower, designed for intricate curves and detailed cuts in wood and softer materials.

Q4: How long should a hacksaw blade last?

A4: This depends heavily on the material being cut, the TPI, the blade quality, and your technique. A good bi-metal blade can last for dozens of cuts on common materials, but a cheap carbon steel blade might dull after just a few tough cuts.

Q5: Do I need different blades for cutting threaded rod versus solid bar stock?

A5: Not necessarily. The primary factor is the diameter and hardness of the material. A 24 TPI bi-metal blade is usually suitable for both threaded rod and solid bar stock of similar diameters. The key is ensuring sufficient teeth engagement with the material.

Q6: Can I cut glass with a hacksaw?

A6: No, you should never attempt to cut glass with a hacksaw. Glass requires specialized cutting tools, typically a glass cutter with a diamond or carbide wheel, and a specific technique to score and snap the glass cleanly.

Conclusion: Cut with Confidence!

There you have it! You’ve learned the secrets to choosing the best hacksaw blades for your projects. Remember, it all comes down to understanding TPI and matching it to the material you’re cutting. For general metalwork, a 24 TPI blade is your reliable workhorse. For finer cuts on thin metal or hard plastics, reach for a 32 TPI blade. And for softer materials like PVC or thicker plastics, an 18 TPI blade will serve you well.

Don’t forget the power of bi-metal blades for their durability and versatility. And always, always prioritize safety by securing your workpiece and using proper cutting techniques. With the right blade and a little practice, you’ll be making clean, precise cuts with confidence on all sorts of materials. So grab your hacksaw, pick the right blade, and get ready to tackle your next project with skill and ease!